To be clear, Polytetrafluoroethylene (PTFE) rotary shaft seals are considered ideal for chemical processing plants primarily due to their exceptional chemical inertness. This material can withstand a vast range of aggressive and corrosive fluids—from strong acids to organic solvents—without degrading, which is a fundamental requirement for maintaining the integrity and reliability of equipment like pumps, mixers, and agitators.

The core reason for choosing PTFE seals in chemical processing is not simply their material resistance; it is the operational stability this resistance provides. By preventing seal failure, PTFE directly translates into reduced maintenance, increased uptime, and enhanced safety when handling hazardous media.

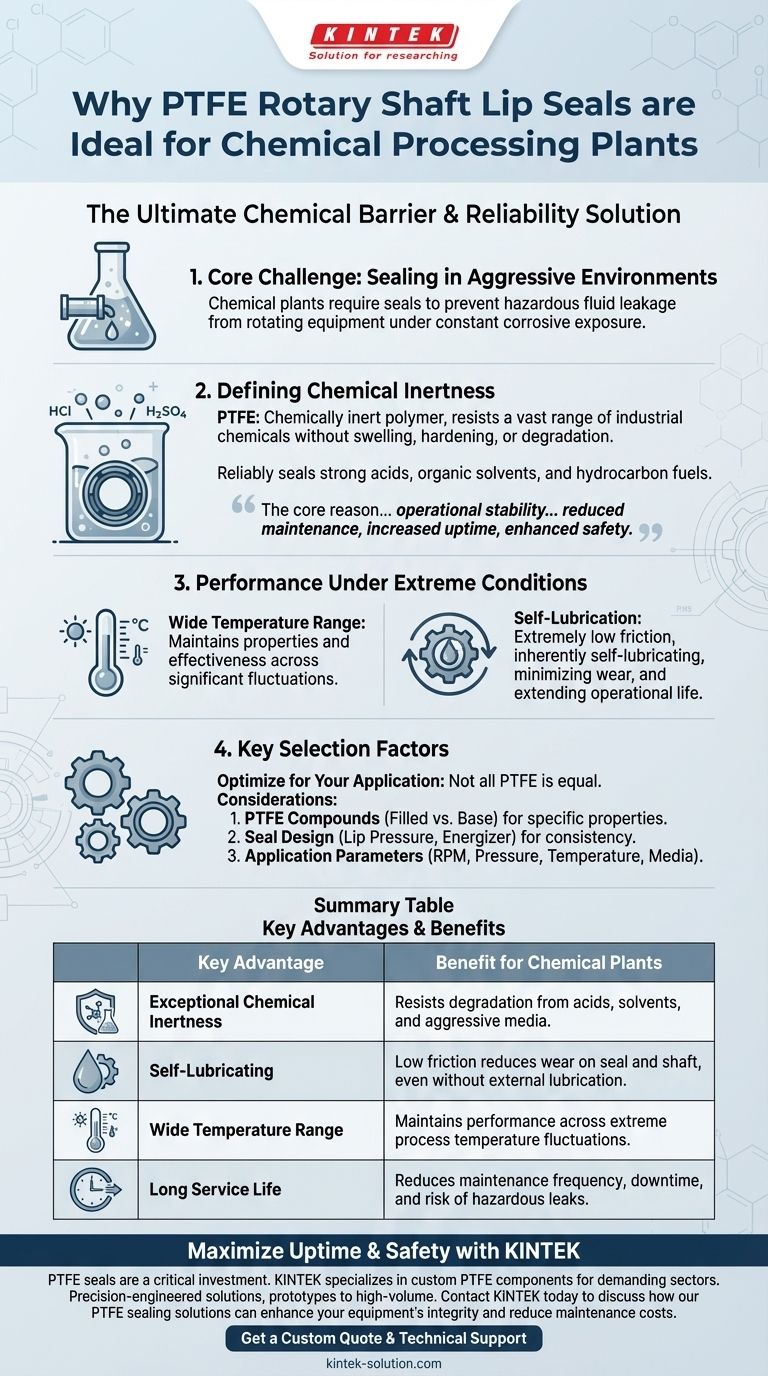

The Core Challenge: Sealing in Aggressive Environments

In a chemical processing plant, the primary function of a rotary seal is to prevent the leakage of fluids from rotating equipment. The constant exposure to corrosive media makes this one of the most demanding sealing applications imaginable.

Defining Chemical Inertness

PTFE is one of the most chemically inert polymers available. It does not react with the vast majority of industrial chemicals.

This means it can reliably seal aggressive media such as hydrochloric acid, sulfuric acid, organic solvents, and hydrocarbon-based fuels without swelling, hardening, or breaking down over time.

Impact on Equipment Integrity

When a seal degrades, it fails. In a chemical plant, this failure can lead to costly downtime, loss of valuable product, and dangerous leaks of hazardous materials.

Because PTFE seals resist chemical attack, they maintain their structural integrity and sealing performance far longer than many traditional elastomers, ensuring the long-term reliability of the equipment they protect.

The Benefit of Self-Lubrication

PTFE has an extremely low coefficient of friction, which means it is inherently self-lubricating.

This property is critical in applications where external lubrication may be minimal or incompatible with the process fluid. It reduces friction and heat generation at the sealing point, minimizing wear and extending the operational life of both the seal and the shaft.

Performance Under Extreme Operating Conditions

Beyond just chemical compatibility, the operational environment in a chemical plant often involves other stressors that PTFE is uniquely equipped to handle.

Wide Temperature Range

Chemical processes can involve significant temperature fluctuations. PTFE seals maintain their properties and sealing effectiveness across a much wider temperature range than most traditional rubber sealing materials.

Durability and Longevity

The combination of chemical resistance, low friction, and temperature stability results in a highly durable seal with a significantly longer lifespan.

This longevity reduces the frequency of seal replacements, directly lowering maintenance costs and minimizing process interruptions.

Understanding the Key Selection Factors

While PTFE is an outstanding material, its successful application depends on selecting the right type of seal for the specific operational parameters. It is not a one-size-fits-all solution.

Not All PTFE Is Equal

Base PTFE can be blended with various fillers (such as carbon, glass fiber, or graphite) to enhance specific properties.

For example, fillers can improve wear resistance, reduce creep, or increase thermal conductivity. Choosing the correct PTFE compound is critical for optimizing performance in a given application.

The Importance of Seal Design

The physical design of the seal lip and the inclusion of an energizer (like a metal spring) are just as important as the material itself.

A well-designed seal ensures consistent lip pressure against the shaft, compensating for wear and maintaining a tight seal even under pressure fluctuations and dynamic conditions.

Matching the Seal to the Application

Factors such as rotational speed (RPM), system pressure, temperature, and the specific chemical media must all be considered. A seal designed for a slow-moving agitator will be different from one intended for a high-speed pump.

How to Apply This to Your Project

Your choice should be guided by the most demanding aspect of your specific application.

- If your primary focus is handling highly corrosive chemicals: Prioritize selecting a PTFE compound that offers the broadest chemical compatibility for the media in your process.

- If your primary focus is high-speed or high-temperature operation: Select a filled PTFE grade and a seal design optimized for thermal stability and low friction to manage heat generation.

- If your primary focus is purity for food or pharmaceutical-grade chemicals: Ensure the PTFE material complies with relevant standards like FDA, 3-A, or NSF/ANSI 61.

Ultimately, leveraging PTFE seals is about investing in the long-term reliability and safety of your critical rotating equipment.

Summary Table:

| Key Advantage | Benefit for Chemical Plants |

|---|---|

| Exceptional Chemical Inertness | Resists degradation from acids, solvents, and aggressive media. |

| Self-Lubricating | Low friction reduces wear on seal and shaft, even without external lubrication. |

| Wide Temperature Range | Maintains performance across extreme process temperature fluctuations. |

| Long Service Life | Reduces maintenance frequency, downtime, and risk of hazardous leaks. |

Maximize Uptime and Safety in Your Chemical Processing Plant

PTFE seals are a critical investment in the reliability of your pumps, mixers, and agitators. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver precision-engineered solutions, from prototypes to high-volume orders, tailored to withstand your specific chemical and operational challenges.

Contact KINTEK today to discuss how our PTFE sealing solutions can enhance your equipment's integrity and reduce maintenance costs.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech