At their core, Teflon encapsulated o-rings provide a significant advantage over traditional elastomeric o-rings by combining the superior chemical and temperature resistance of a Teflon outer jacket with the flexibility and reliable sealing force of an inner elastomer core. This dual-material design allows them to succeed in hostile environments where a standard rubber o-ring would quickly fail.

The fundamental advantage is synergy: you get the chemical inertness and low-friction surface of Teflon without sacrificing the essential elasticity that a standard rubber o-ring provides for a reliable, long-term seal.

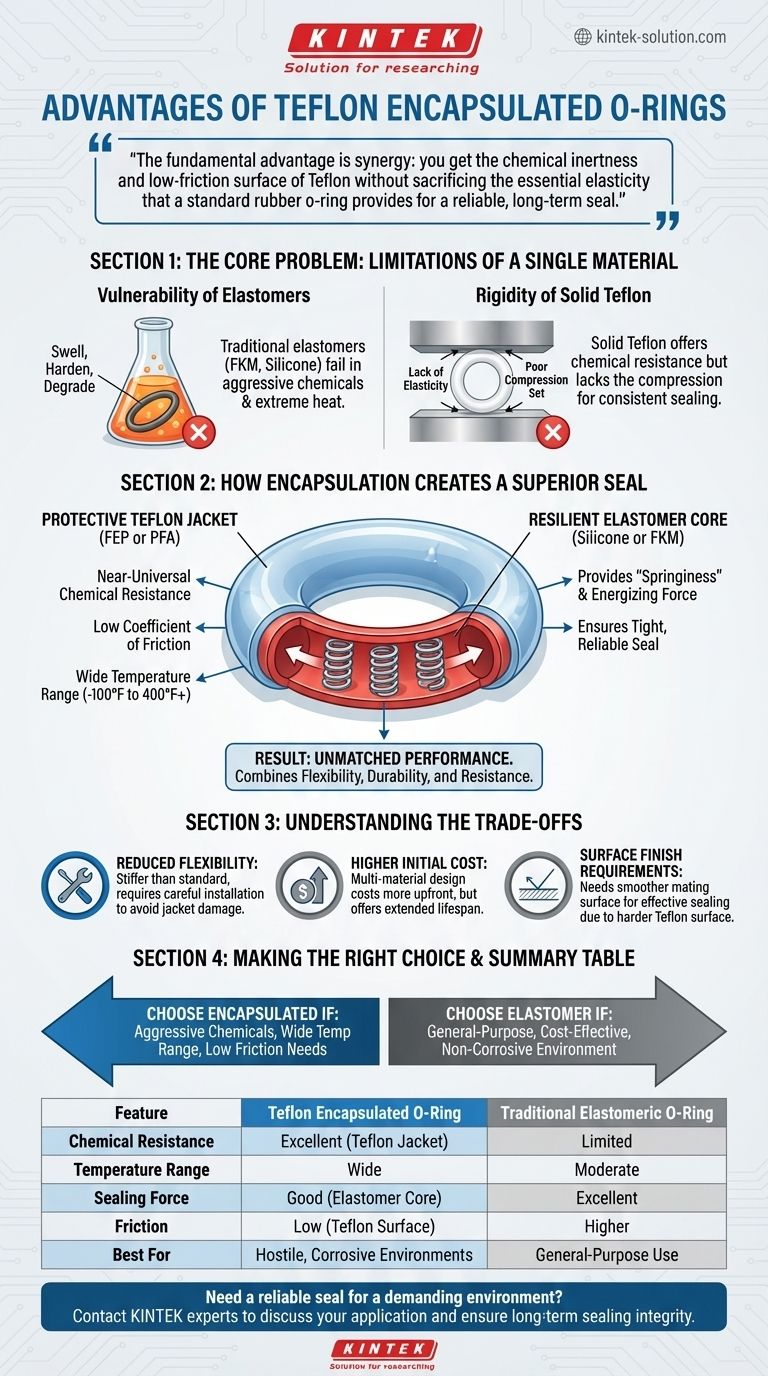

The Core Problem: Limitations of a Single Material

To understand the value of encapsulation, we must first recognize the inherent limitations of using either an elastomer or solid Teflon alone for demanding sealing applications.

The Vulnerability of Elastomers

Traditional o-rings made from elastomers like FKM (Viton®), Silicone, or EPDM are excellent for general-purpose sealing.

However, they possess a limited tolerance for aggressive chemicals and extreme temperatures. Exposure to corrosive solvents, acids, or high heat can cause them to swell, harden, or degrade, leading to seal failure.

The Rigidity of Solid Teflon

Solid PTFE (Teflon) o-rings offer nearly universal chemical resistance and a vast temperature range.

Their critical weakness is a lack of elasticity. They do not compress and rebound effectively, a property known as "compression set." This rigidity makes it difficult for them to maintain a consistent sealing force, especially under fluctuating pressures or temperatures.

How Encapsulation Creates a Superior Seal

A Teflon encapsulated o-ring is engineered to overcome the weaknesses of each material by combining their strengths into a single, high-performance component.

The Protective Teflon "Jacket"

The seamless outer layer is a thin jacket of Teflon, typically FEP or PFA. This shell acts as the first line of defense.

It provides the o-ring with its signature properties: near-universal chemical resistance, a low coefficient of friction for dynamic applications, and excellent performance across a wide temperature range.

The Resilient Elastomer Core

Inside the Teflon jacket is a standard elastomeric o-ring, most commonly Silicone or FKM (Viton®).

This inner core is completely protected from the external environment. Its sole purpose is to provide the "springiness" or energizing force, pushing the outer Teflon jacket against the sealing surfaces to create a tight, reliable seal.

The Result: Unmatched Performance

This composite design delivers a seal that outperforms traditional elastomers in several key areas.

It provides the flexibility and compression needed for effective sealing while simultaneously offering the durability and resistance required to survive in hostile chemical and thermal environments.

Understanding the Trade-offs

While highly effective, encapsulated o-rings are not a universal replacement for all standard o-rings. Acknowledging their specific characteristics is key to proper application.

Reduced Flexibility

The Teflon jacket makes the o-ring significantly stiffer than a standard elastomer seal. This can make installation more challenging and requires greater care to avoid creasing or damaging the jacket, which would compromise the seal.

Higher Initial Cost

The multi-material construction and more complex manufacturing process result in a higher upfront cost compared to standard elastomeric o-rings. However, this cost is often justified by extended equipment lifespan and reduced maintenance downtime in aggressive applications.

Surface Finish Requirements

Because the Teflon surface is harder and less compliant than rubber, it requires a smoother mating surface to achieve an effective seal. Any imperfections in the hardware are less likely to be compensated for by the seal material itself.

Making the Right Choice for Your Application

Selecting the correct o-ring requires matching the material's capabilities to the demands of the environment.

- If your primary focus is sealing against aggressive chemicals or solvents: The encapsulated o-ring is the definitive choice for ensuring seal integrity and longevity.

- If your application involves a very wide temperature range: The encapsulated design offers a much broader operational window than most standard elastomers can provide.

- If you need to reduce friction in a dynamic (moving) seal: The low-friction Teflon surface provides a significant performance advantage, reducing wear and drag.

- If you need a cost-effective, general-purpose seal for a non-corrosive environment: A standard elastomeric o-ring is likely the more practical and economical solution.

Ultimately, choosing an encapsulated o-ring is an investment in reliability for applications where standard seals are simply not sufficient.

Summary Table:

| Feature | Teflon Encapsulated O-Ring | Traditional Elastomeric O-Ring |

|---|---|---|

| Chemical Resistance | Excellent (Teflon jacket) | Limited |

| Temperature Range | Wide (e.g., -100°F to 400°F+) | Moderate |

| Sealing Force/Elasticity | Good (from inner elastomer core) | Excellent |

| Friction | Low (Teflon surface) | Higher |

| Best For | Hostile, corrosive environments | General-purpose, non-corrosive use |

Need a reliable seal for a demanding environment?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom Teflon encapsulated o-rings. Our seals are engineered for the semiconductor, medical, laboratory, and industrial sectors, where failure is not an option.

We combine precision production with custom fabrication to deliver the exact solution you need, from prototypes to high-volume orders.

Contact our experts today to discuss your application and ensure long-term sealing integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers