At its core, the installation benefits of expanded PTFE (ePTFE) gaskets stem from two primary material characteristics: their exceptional softness and their high degree of compressibility. This unique combination allows them to be easily cut and shaped by hand on-site, while also conforming perfectly to irregular or damaged flange surfaces with minimal effort, creating a reliable seal where more rigid materials would fail.

The true value of expanded PTFE isn't just that it's easier to install. Its installation benefits are a direct result of the material properties that also create a more forgiving and durable seal, especially on the imperfect surfaces common in real-world industrial environments.

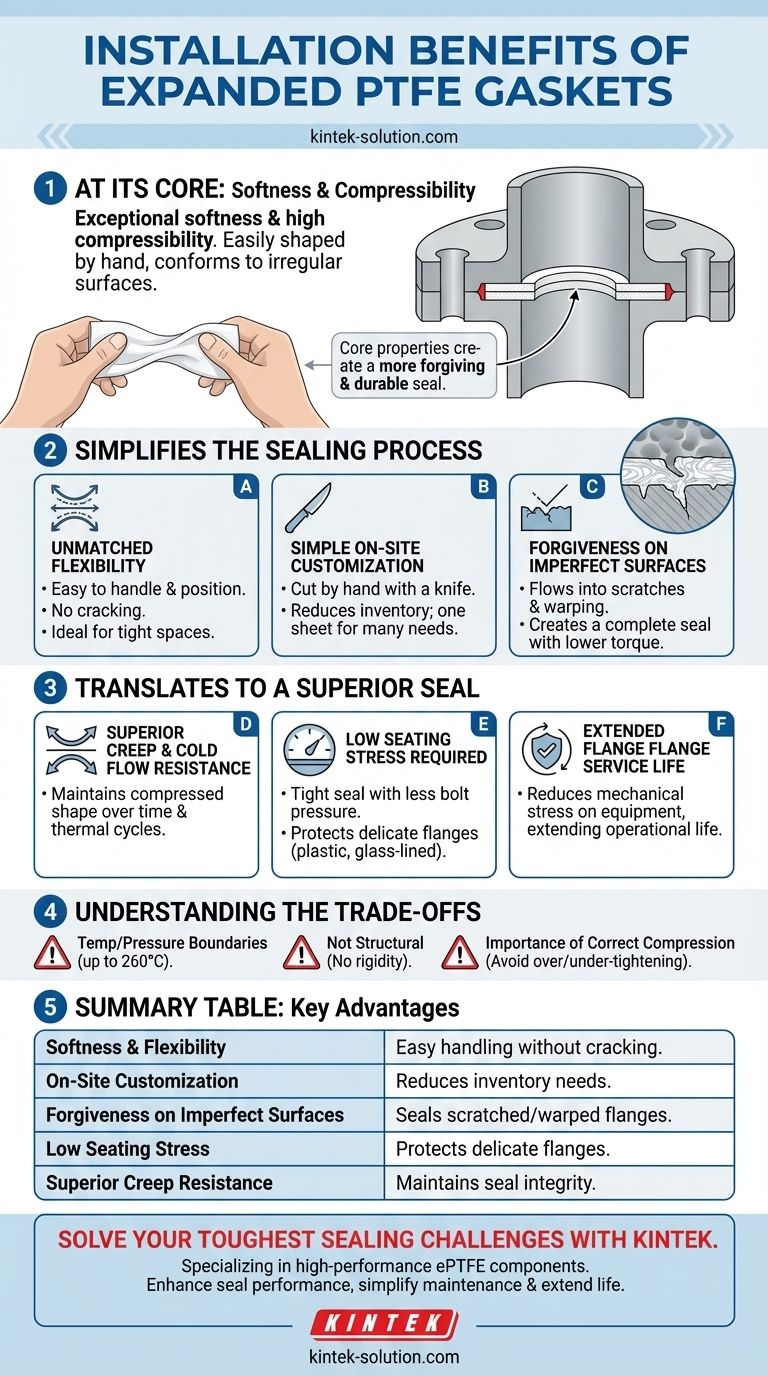

Why Expanded PTFE Simplifies the Sealing Process

The advantages of ePTFE become clear when you compare it to standard, rigid gaskets. The installation process is fundamentally less demanding and more tolerant of common flaws.

Unmatched Softness and Flexibility

Expanded PTFE is remarkably soft and pliable. This makes the gasket easy to handle and position during installation without the risk of cracking or breaking.

This flexibility allows it to be used in complex shapes or tight spaces where manipulating a rigid gasket would be difficult or impossible.

Simple On-Site Customization

Unlike gaskets that must be precisely pre-cut, ePTFE material can be conveniently cut by hand with a simple knife or blade.

This eliminates the need for a large inventory of different-sized gaskets. A single roll or sheet can be used to create custom seals for various flange sizes and configurations directly in the field, saving time and reducing waste.

Forgiveness on Imperfect Surfaces

This is the most critical installation benefit. The soft, compressible nature of ePTFE allows it to flow into and fill the microscopic imperfections common on flange faces, such as scratches, pits, or slight warping.

Where a standard gasket might create leak paths over these irregularities, ePTFE deforms to create a complete, uniform seal with lower initial bolt torque.

How Installation Benefits Translate to a Superior Seal

The same properties that make ePTFE easy to install are also what make it a highly reliable sealing material. The ease of use is a symptom of its superior performance capabilities.

Superior Creep and Cold Flow Resistance

A common failure point for standard PTFE is "creep" or "cold flow," where the material slowly deforms and flows out from under the pressure of the bolts, causing the seal to loosen.

Expanded PTFE is specifically engineered to resist this phenomenon. It maintains its compressed shape and sealing capability over long periods and through thermal cycles, ensuring a durable, long-lasting seal.

Low Seating Stress Required

Because ePTFE is so conformable, it achieves a tight seal without requiring extreme bolt pressure (clamping force).

This is a significant advantage for protecting delicate or older equipment, such as plastic, glass-lined, or fiberglass-reinforced flanges, which could crack under the high torque required to seat a harder gasket material.

Extended Flange Service Life

By compensating for minor flange deformation and requiring less clamping force, ePTFE gaskets reduce the mechanical stress placed on the flanges themselves. This can help extend the operational life of your equipment.

Understanding the Trade-offs

While highly effective, ePTFE is not a universal solution. Understanding its limitations is key to using it successfully.

Temperature and Pressure Boundaries

Expanded PTFE has an excellent temperature range, typically from cryogenic levels up to 260°C (500°F). However, it is not suitable for applications that exceed this limit. Always confirm the specific product's pressure and temperature ratings against your system's requirements.

Not a Structural Component

Expanded PTFE is strictly a sealing material. Its softness means it provides no structural rigidity and cannot be used to correct significant flange misalignment or large gaps. The flange connection must be structurally sound on its own.

Importance of Correct Compression

While forgiving, ePTFE is not immune to poor installation practices. Extreme over-tightening can damage the gasket's porous structure, and insufficient torque will fail to create an initial seal. Following the manufacturer's recommended torque values is still essential for reliability.

Making the Right Choice for Your Application

Selecting the right gasket comes down to matching the material's strengths to your primary challenge.

- If your primary focus is sealing old, warped, or damaged flanges: The unmatched conformability of ePTFE makes it the ideal choice to compensate for surface imperfections.

- If your primary focus is simplifying field maintenance and inventory: The ability to cut ePTFE on-site from a single sheet or roll makes it a versatile and efficient solution.

- If your primary focus is protecting fragile or non-metallic flanges: The ability of ePTFE to seal effectively at low bolt loads prevents damage to delicate equipment.

By understanding that its installation advantages are intrinsically linked to its performance, you can confidently specify expanded PTFE to solve your most challenging sealing problems.

Summary Table:

| Installation Benefit | Key Advantage |

|---|---|

| Softness & Flexibility | Easy handling and positioning without cracking. |

| On-Site Customization | Cut by hand to reduce inventory needs. |

| Forgiveness on Imperfect Surfaces | Seals effectively on scratched or warped flanges. |

| Low Seating Stress | Protects delicate flanges with minimal bolt torque. |

| Superior Creep Resistance | Maintains seal integrity over time and thermal cycles. |

Solve Your Toughest Sealing Challenges with KINTEK

Struggling with leaky, damaged, or hard-to-seal flanges? KINTEK specializes in manufacturing high-performance expanded PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our ePTFE gaskets offer unmatched installation ease and long-term reliability, thanks to precision engineering and custom fabrication from prototypes to high-volume orders.

Let us help you enhance seal performance, simplify maintenance, and extend equipment life. Contact KINTEK today for a tailored solution that meets your exact needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications