The primary reason PTFE is specified for rotary shaft applications is its unique combination of an extremely low coefficient of friction and high thermal and chemical stability. This allows PTFE seals, bushings, and bearings to operate reliably at high speeds and temperatures, often without external lubrication, while resisting degradation from aggressive media.

While many materials can handle a single challenging condition, PTFE excels across a wide operational spectrum—high speed, high pressure, extreme temperatures, and aggressive chemicals. Its value lies not in a single property, but in its reliable, integrated performance when these demanding factors converge.

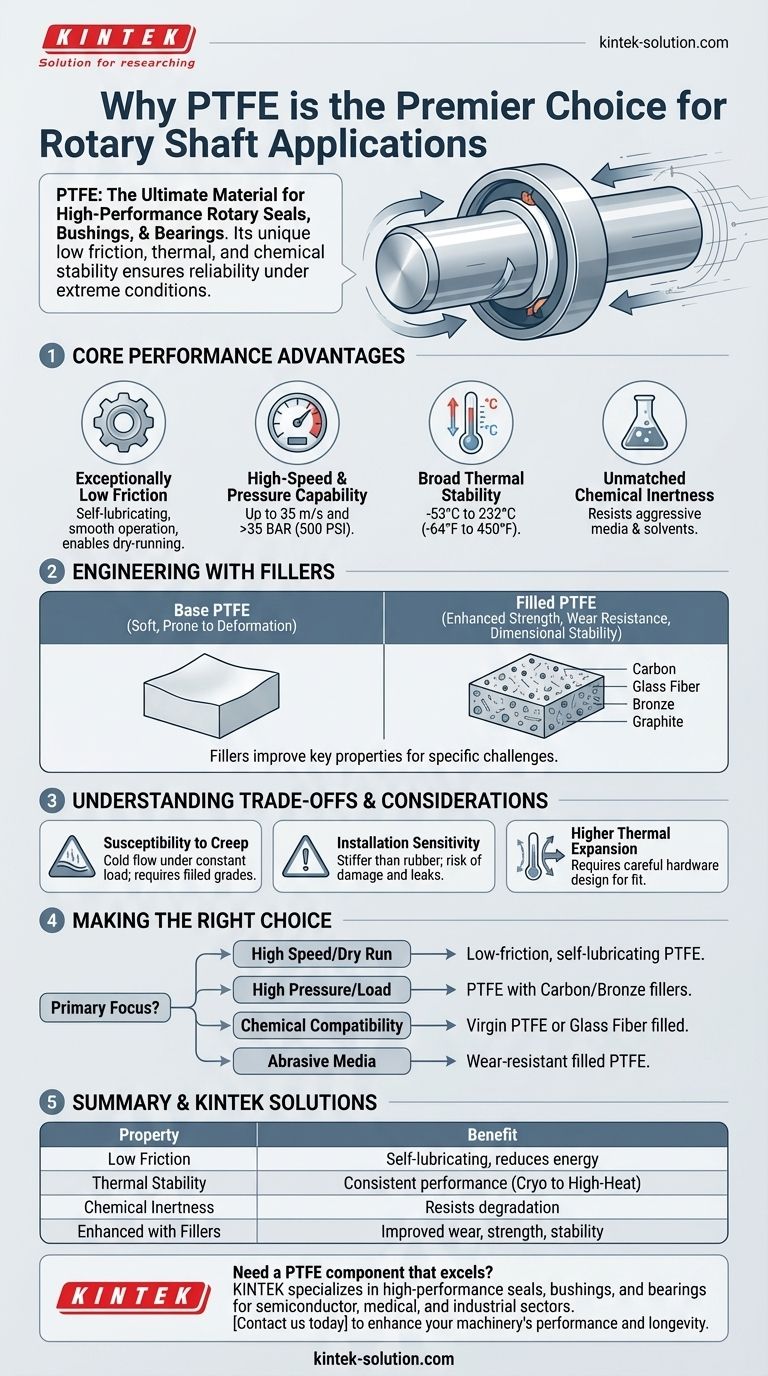

The Core Performance Advantages of PTFE

PTFE's fundamental characteristics make it a default choice for engineers designing systems with rotating shafts, where managing friction, heat, and wear is paramount.

Exceptionally Low Friction

PTFE is inherently self-lubricating, possessing one of the lowest coefficients of friction of any solid material.

This property virtually eliminates stick-slip behavior and minimizes the initial breakout friction required to start motion. The result is smoother operation, lower energy consumption, and suitability for dry-running applications where traditional lubricants are undesirable or impossible to use.

High-Speed and High-Pressure Capability

Compared to traditional elastomeric seals, PTFE compounds can operate in far more demanding dynamic conditions.

They are engineered to handle shaft surface speeds up to 35 m/s and system pressures exceeding 35 BAR (500 PSI). This performance envelope allows for more compact and efficient machinery designs.

Broad Thermal Stability

PTFE maintains its integrity across an exceptionally wide temperature range, typically from -53°C to 232°C (-64°F to 450°F).

This stability ensures consistent sealing performance in environments ranging from cryogenic systems to high-heat automotive engines and industrial gearboxes, where other materials would quickly fail.

Unmatched Chemical Inertness

PTFE is inert to nearly all industrial chemicals, solvents, and lubricants.

This chemical resistance guarantees that the seal or bearing will not swell, soften, or degrade when exposed to the operating medium, ensuring long-term reliability and preventing leaks.

Engineering PTFE for Specific Demands

While pure PTFE offers remarkable properties, its true potential is unlocked by blending it with fillers to create composite materials tailored to specific challenges.

The Critical Role of Fillers

Base PTFE can be relatively soft and prone to deformation under load.

By adding fillers like carbon, glass fiber, bronze, or graphite, manufacturers can dramatically improve key mechanical properties. These enhancements target specific weaknesses to create a more robust material.

Enhanced Strength and Wear Resistance

Fillers significantly increase compressive strength, stiffness, and wear resistance.

This makes the material less prone to extrusion under high pressure and more durable in the presence of abrasive particles. A properly selected filled PTFE component not only lasts longer but can also eliminate wear on the shaft itself.

Dimensional Stability

Improved stiffness and thermal conductivity from fillers give PTFE composites excellent dimensional stability.

The material maintains its precise shape and sealing force under mechanical load and across temperature fluctuations, which is crucial for preventing leaks in dynamic applications.

Understanding the Trade-offs and Considerations

No material is perfect. Acknowledging the inherent limitations of PTFE is key to successful application design.

Susceptibility to Creep

Unfilled PTFE can be prone to "cold flow," or creep, where the material slowly deforms under a constant load. This is a primary reason why filled grades are necessary for most high-load structural or sealing applications.

Installation Sensitivity

PTFE seals are generally stiffer and less forgiving than their rubber counterparts. Care must be taken during installation to avoid scratching the seal lip or the shaft, as minor damage can create a significant leak path.

Higher Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. Hardware design must account for this to ensure that the proper interference fit and sealing force are maintained across the entire operating temperature range.

Making the Right Choice for Your Application

The optimal PTFE solution depends entirely on balancing the specific demands of your operating environment.

- If your primary focus is high speed and dry running: A low-friction, self-lubricating PTFE compound is essential to minimize heat generation and wear.

- If your primary focus is high pressure and load: Select a PTFE blend with fillers like carbon or bronze to improve compressive strength and resist creep.

- If your primary focus is chemical compatibility: A virgin PTFE or a formulation with a chemically inert filler like glass fiber is the safest choice to ensure seal integrity.

- If your primary focus is operation in abrasive media: A wear-resistant filled PTFE is required to prevent premature failure of the seal and protect the shaft surface.

By understanding these core properties and trade-offs, you can specify a PTFE material that delivers exceptional reliability in the most demanding rotary applications.

Summary Table:

| Property | Benefit for Rotary Shaft Applications |

|---|---|

| Low Coefficient of Friction | Self-lubricating, reduces energy use, enables dry-running |

| High Thermal Stability (-53°C to 232°C) | Consistent performance from cryogenic to high-heat environments |

| Chemical Inertness | Resists degradation from aggressive chemicals and solvents |

| Enhanced with Fillers | Improved wear resistance, compressive strength, and dimensional stability |

Need a PTFE component that excels in your specific rotary application?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, bushings, and bearings tailored to the unique demands of the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard solution or a custom fabrication—from prototypes to high-volume orders—our precision production ensures reliability under high speed, pressure, and temperature.

Contact us today to discuss how our PTFE solutions can enhance your machinery's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE perform against stainless steel in terms of friction? Discover Unmatched Low-Friction Performance

- What installation methods are available for PTFE slide bearings? Choose the Right Method for Your Structure

- What are some common applications of machined Teflon? Critical Components for Harsh Environments

- What are the limitations of using PTFE in sealing applications? Overcome Mechanical Weaknesses for Reliable Sealing

- What are the key properties of PTFE that make it suitable for sealing rings? Unmatched Chemical & Thermal Resistance

- Why is PTFE's chemical resistance significant for shaft seals? Ensuring Leak-Free Performance in Harsh Environments

- What are the different types of washers made from Teflon sheets? Choose the Right PTFE Washer for Your Application

- What are the long-term benefits of using PTFE lined butterfly valves? Achieve Lower Costs & Superior Reliability