In a direct comparison, Polytetrafluoroethylene (PTFE) exhibits exceptionally low friction when sliding against stainless steel. This combination results in one of the lowest coefficients of friction ever recorded between two solid materials, often outperforming even lubricated steel-on-steel contact. The interaction is less about which material "wins" and more about how the two work together to create an incredibly efficient, low-resistance system.

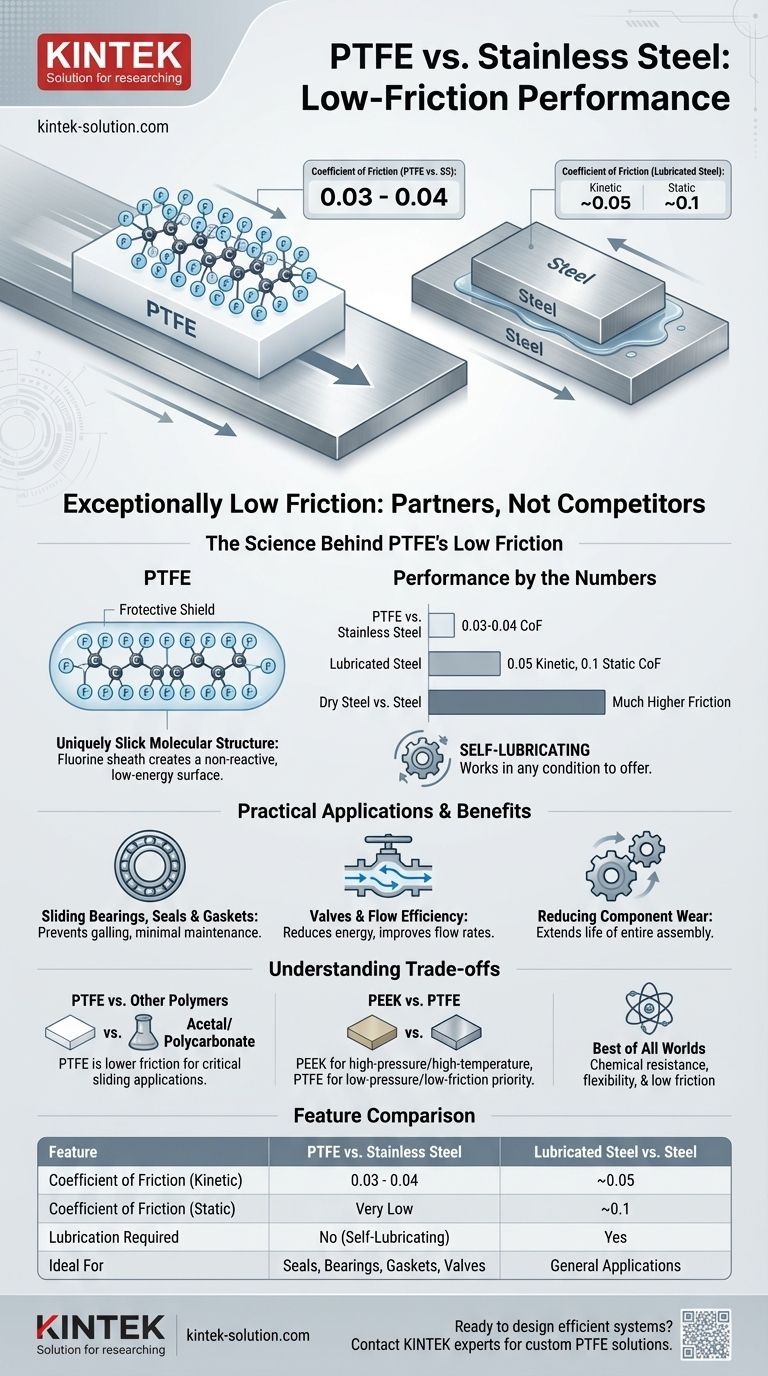

The core insight is not to view PTFE and stainless steel as competitors, but as partners. Using a PTFE surface against a stainless steel component creates a system with a coefficient of friction so low (0.03 to 0.04) that it often eliminates the need for liquid lubricants entirely.

The Science Behind PTFE's Low Friction

The performance of PTFE is rooted in its unique molecular structure, which translates directly into measurable real-world advantages.

A Uniquely Slick Molecular Structure

PTFE's properties are not accidental; they are a direct result of its chemical makeup. Its long, simple carbon chains are completely sheathed by fluorine atoms.

This fluorine sheath creates a very smooth, low-energy surface that is highly non-reactive and repels other substances, which is why materials do not readily stick to it.

The Coefficient of Friction by the Numbers

When measured, the performance is remarkable. The coefficient of friction for PTFE against stainless steel can be as low as 0.03 to 0.04.

To put that in perspective, even lubricated steel-on-steel has a kinetic (moving) coefficient of friction around 0.05 and a static (starting) friction of 0.1.

Performance in Any Condition

A key advantage of PTFE is its consistency. It maintains its low-friction properties in both dry and lubricated environments.

This effectively makes it self-lubricating, providing reliable performance where traditional lubricants might fail, degrade, or be undesirable.

Why This Matters in Practical Applications

This extremely low friction has profound implications for the design and efficiency of mechanical systems.

Bearings, Seals, and Gaskets

For any application requiring parts to slide against one another, PTFE is a premier choice.

Its non-stick nature prevents galling and seizing, making it ideal for creating durable sliding bearings, high-performance seals, and reliable gaskets that require minimal maintenance.

Valves and Flow Efficiency

In PTFE-lined valves, the slick surface significantly reduces the energy required to operate the mechanism.

This not only lowers operational costs but also improves flow rates, allowing more material to be processed compared to valves made from other materials.

Reducing Component Wear

Because PTFE is so smooth, it dramatically reduces wear and tear on the mating surface, such as a stainless steel shaft or housing.

This extends the operational life of the entire assembly, not just the PTFE component itself.

Understanding the Broader Context and Trade-offs

While PTFE's friction performance is elite, selecting the right material requires understanding its position relative to other engineering plastics and its operational limits.

Comparison with Other Polymers

Compared to common plastics like Acetal or Polycarbonate, PTFE's coefficient of friction is exceptionally lower, making it the clear choice for critical sliding applications.

However, other high-performance polymers exist. PEEK, for example, also offers low friction and excellent chemical resistance. The key difference lies in its mechanical strength under load.

The PEEK vs. PTFE Scenario

PEEK excels in high-pressure and high-temperature scenarios where structural integrity is paramount.

PTFE is better suited for high-temperature but low-to-medium pressure applications where the absolute lowest friction is the primary goal.

Balancing Multiple Properties

PTFE often represents a "best of all worlds" solution. While rubber expansion joints offer more flexibility and metal bellows handle higher pressure, PTFE uniquely combines excellent chemical resistance, good flexibility, and elite low-friction performance.

Making the Right Choice for Your Goal

Your specific engineering goal will determine if the PTFE-on-steel system is the optimal choice for your application.

- If your primary focus is achieving the lowest possible friction: The combination of PTFE sliding against stainless steel is one of the best performing systems available.

- If your primary focus is handling high pressure and high temperature simultaneously: PEEK may be a more suitable alternative due to its superior mechanical strength under load.

- If your primary focus is balancing chemical resistance, flexibility, and performance: PTFE provides a versatile and highly effective solution that outperforms many specialized materials.

Ultimately, leveraging PTFE's properties with a durable material like stainless steel is a foundational strategy for designing efficient and long-lasting mechanical systems.

Summary Table:

| Feature | PTFE vs. Stainless Steel | Lubricated Steel vs. Steel |

|---|---|---|

| Coefficient of Friction (Kinetic) | 0.03 - 0.04 | ~0.05 |

| Coefficient of Friction (Static) | Very Low | ~0.1 |

| Lubrication Required | No (Self-Lubricating) | Yes |

| Ideal For | Seals, Bearings, Gaskets, Valves | General Applications |

Ready to design more efficient, low-friction systems? KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact PTFE solution to minimize friction and maximize performance. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance