At their core, Teflon sheet washers are categorized into three functional types designed for distinct mechanical tasks. These are plain washers for distributing load, spring washers for resisting vibration, and locking washers for preventing fasteners from rotating loose. Each type leverages the unique properties of Teflon to perform its role in specific environments.

The choice between a plain, spring, or locking Teflon washer is not about the material itself, but about the mechanical problem you need to solve: distributing pressure, absorbing vibration, or preventing loosening. Teflon simply adds its signature low-friction and chemical resistance benefits to the solution.

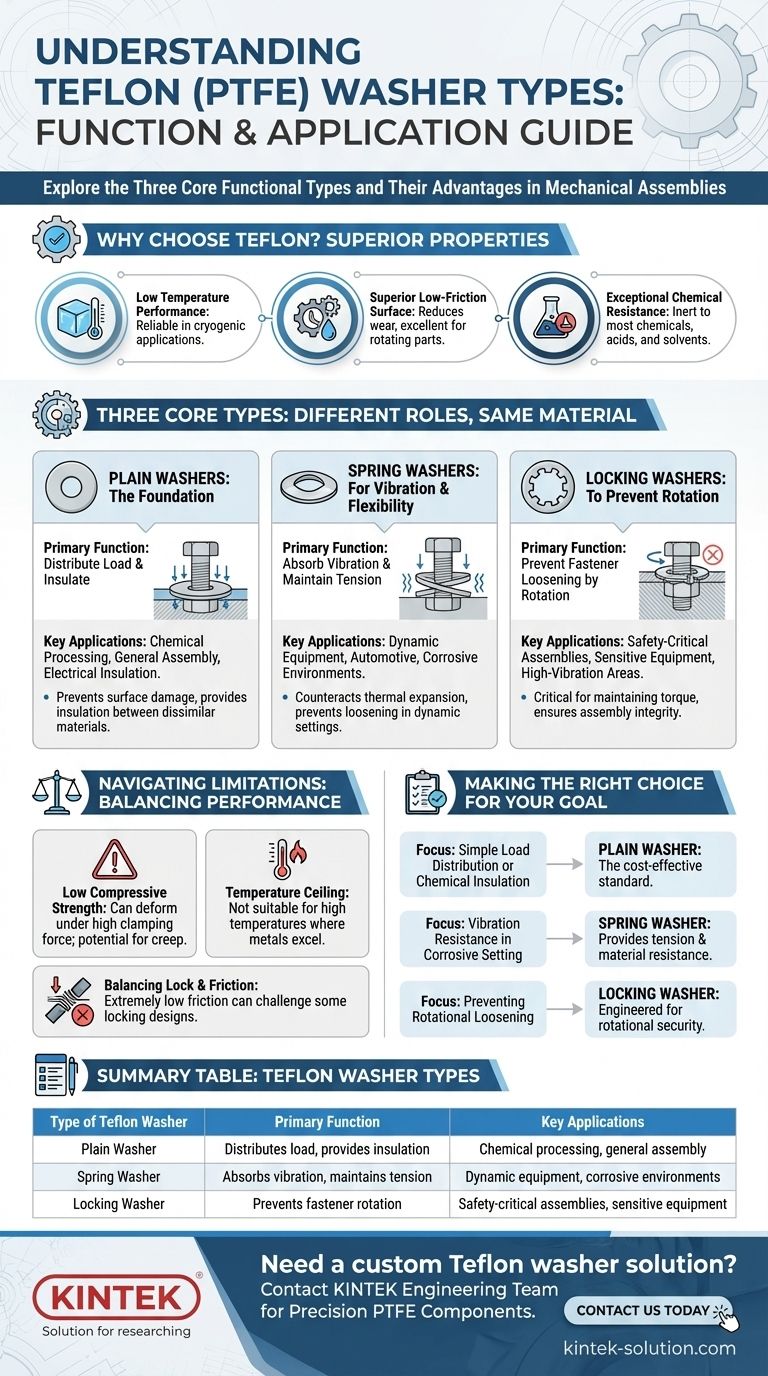

The Unique Advantages of Teflon (PTFE)

Before examining the types, it's crucial to understand why Teflon, or Polytetrafluoroethylene (PTFE), is selected as a washer material. Its properties make it ideal for applications where metal washers would fail.

Superior Low-Friction Surface

Teflon possesses one of the lowest coefficients of friction of any solid material. This makes it an excellent choice for applications with rotating parts, as it reduces wear and binding.

Exceptional Chemical Resistance

These washers are virtually inert and resistant to most chemicals, acids, and solvents. This makes them indispensable in corrosive environments found in the chemical processing, automotive, and plumbing industries.

Performance in Low Temperatures

While many materials become brittle in the cold, Teflon maintains its properties at very low temperatures, ensuring reliability in cryogenic or refrigerated applications.

The Three Core Types of Teflon Washers

Each type of Teflon washer is engineered to solve a different mechanical challenge.

1. Plain Washers: The Foundation

A plain Teflon washer is a simple flat disc with a central hole. Its primary job is to distribute the load of a threaded fastener, like a screw or nut, over a wider surface area.

This prevents damage to the surface of the components being joined and can also provide electrical or chemical insulation between materials.

2. Spring Washers: For Vibration and Flexibility

Teflon spring washers are not flat. They are formed into a shape that provides axial flexibility, allowing them to act like a spring.

Their purpose is to counteract vibration and thermal expansion. They exert continuous pressure on the fastener, creating tension that helps prevent it from gradually loosening in dynamic environments.

3. Locking Washers: To Prevent Rotation

Locking washers are specifically designed to stop a fastener from loosening due to rotation. While many locking washers are metal and rely on "biting" into the material, Teflon versions can use friction or shape to achieve a similar effect.

They are critical in assemblies where maintaining bolt torque is essential for safety and reliability, adding Teflon's low-friction and non-corrosive benefits.

Understanding the Trade-offs

While highly versatile, Teflon is not a universal solution. Understanding its limitations is key to proper application.

Low Compressive Strength

Compared to metal, Teflon is a soft material. In applications with extremely high clamping forces, a plain Teflon washer can deform or "creep" over time, leading to a loss of preload.

Temperature Ceiling

Although excellent for low temperatures, Teflon has a relatively low melting point compared to metals. It is not suitable for high-temperature applications where a steel or ceramic washer would be required.

Balancing Lock and Friction

The very low-friction nature of Teflon can be a disadvantage for some locking washer designs that rely on high static friction to prevent rotation. The design must be chosen carefully to ensure it can function effectively with a low-friction material.

Making the Right Choice for Your Goal

Selecting the correct washer is about matching its mechanical function and material properties to your specific need.

- If your primary focus is simple load distribution or chemical insulation: A plain Teflon washer is the standard, cost-effective choice.

- If your primary focus is preventing loosening from vibration in a corrosive setting: A Teflon spring washer provides the necessary tension and material resistance.

- If your primary focus is stopping a fastener from rotating loose in a sensitive assembly: A Teflon locking washer is engineered to provide rotational security.

By understanding the distinct role of each washer type, you can leverage the powerful benefits of Teflon to ensure the integrity and longevity of your assembly.

Summary Table:

| Type of Teflon Washer | Primary Function | Key Applications |

|---|---|---|

| Plain Washer | Distributes load, provides insulation | Chemical processing, general assembly |

| Spring Washer | Absorbs vibration, maintains tension | Dynamic equipment, corrosive environments |

| Locking Washer | Prevents fastener rotation | Safety-critical assemblies, sensitive equipment |

Need a custom Teflon washer solution for your specific requirements?

At KINTEK, we specialize in manufacturing precision PTFE components (including seals, liners, labware, and custom washers) for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures you get the right washer type with optimal material properties for your application.

Contact our engineering team today to discuss your project and receive a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the aerospace and defense applications of PTFE? Essential for Extreme Reliability

- Where is PTFE packing typically used? The Go-To Sealing Solution for Harsh Environments

- Why is PTFE considered important in RF PCB applications? Ensure Superior Signal Integrity

- How do PTFE and EPDM valve seats perform in actuated butterfly valves? Choose the Right Seal for Your Media

- What are the main advantages of using Teflon gland packing? Achieve Superior Sealing and Lower Costs

- What is PTFE and why is it used in mechanical seals? Unmatched Chemical Resistance & Low Friction

- How do expanded PTFE gaskets compare to rubber or plastic seals in terms of lifespan? Last Up to 7x Longer

- What is expanded PTFE gasket material and how is it produced? A Guide to Superior Sealing Performance