The primary advantages of Teflon gland packing stem from its unique molecular structure, which provides exceptional chemical resistance, a vast temperature tolerance, and an extremely low coefficient of friction. These core properties work together to deliver superior sealing performance, protect expensive equipment from wear, and reduce long-term maintenance costs in demanding industrial environments.

While often selected for its resistance to harsh chemicals and extreme temperatures, the true operational value of Teflon (PTFE) packing lies in its ability to minimize friction. This single characteristic reduces equipment wear, lowers energy consumption, and extends service intervals, leading to a lower total cost of ownership.

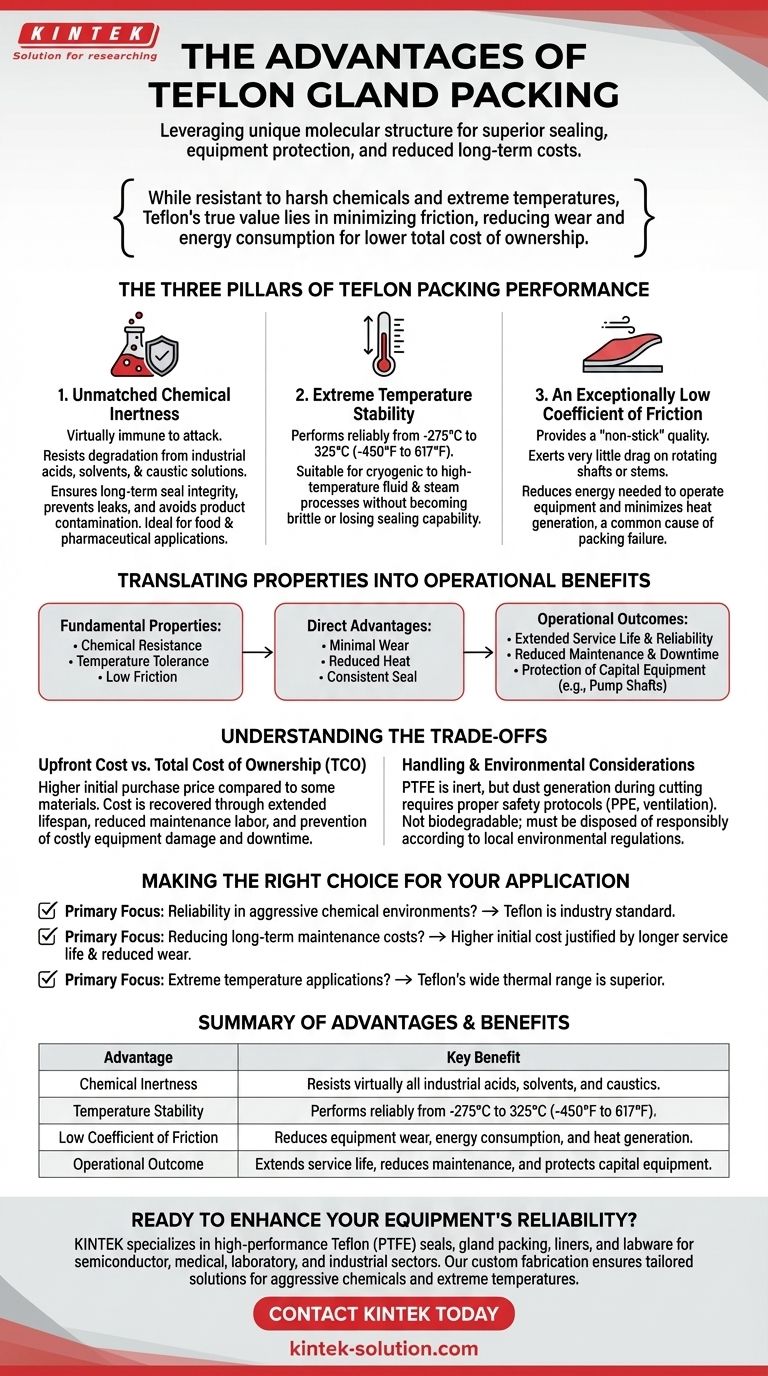

The Three Pillars of Teflon Packing Performance

The effectiveness of Teflon, or Polytetrafluoroethylene (PTFE), packing can be understood by examining three fundamental material properties. These characteristics are the reason it is specified for so many critical applications.

Unmatched Chemical Inertness

Teflon packing is virtually immune to chemical attack. It will not swell, degrade, or dissolve when exposed to the vast majority of industrial acids, solvents, and caustic solutions.

This chemical inertness ensures the integrity of the seal is maintained over time, preventing dangerous leaks and product contamination. It is also why PTFE is a go-to material for food processing and pharmaceutical applications.

Extreme Temperature Stability

Teflon performs reliably across an exceptionally wide temperature range, from as low as -275°C (-450°F) to as high as 325°C (617°F).

This allows it to be used in everything from cryogenic services to high-temperature fluid and steam applications without becoming brittle or losing its sealing capability.

An Exceptionally Low Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any solid material, giving it a characteristic "non-stick" quality.

In a pump or valve, this means the packing exerts very little drag on a rotating shaft or moving stem. This directly reduces the energy needed to operate the equipment and minimizes heat generation at the sealing point, which is a common cause of packing failure.

Translating Properties into Operational Benefits

The fundamental characteristics of Teflon create tangible advantages in day-to-day operations, impacting everything from equipment health to the bottom line.

Extended Service Life and Reliability

Because Teflon packing resists chemical degradation and causes minimal wear on moving parts, it simply lasts longer. This results in superior, long-term sealing performance you can depend on.

Reduced Maintenance and Downtime

A longer service life directly translates to fewer shutdowns for repacking pumps, mixers, and valves. For any production facility, minimizing scheduled and unscheduled downtime is a significant financial and operational benefit.

Protection of Capital Equipment

The low-friction nature of Teflon packing significantly reduces wear on expensive equipment components like pump shafts and sleeves. Over the life of a machine, this can save thousands in repair and replacement costs.

Understanding the Trade-offs

To make an informed decision, it's critical to evaluate the complete picture, including the potential downsides.

Upfront Cost vs. Total Cost of Ownership

Teflon gland packing typically has a higher initial purchase price compared to some conventional packing materials like graphite or vegetable fiber.

However, this higher upfront cost is often recovered multiple times over. The return on investment comes from its extended lifespan, reduced need for maintenance labor, and prevention of costly equipment damage and operational downtime.

Handling and Environmental Considerations

While the final product is inert and safe, PTFE dust can be generated when cutting or removing old packing. Proper safety protocols, including personal protective equipment (PPE) and good ventilation, should always be followed.

Furthermore, Teflon is not biodegradable. This means that used packing material must be disposed of responsibly according to local environmental regulations.

Making the Right Choice for Your Application

Choosing the correct packing material depends entirely on your operational priorities.

- If your primary focus is reliability in aggressive chemical environments: Teflon packing is an industry standard, offering a seal that will not degrade when exposed to nearly all industrial fluids.

- If your primary focus is reducing long-term maintenance costs: The higher initial cost of Teflon packing is often justified by its significantly longer service life and the reduction in associated equipment wear.

- If you are operating in applications with extreme temperatures: Teflon's wide thermal operating range makes it a superior choice for processes involving both cryogenic cold and significant heat.

Ultimately, selecting Teflon gland packing is an investment in operational stability and long-term efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resists virtually all industrial acids, solvents, and caustics. |

| Temperature Stability | Performs reliably from -275°C to 325°C (-450°F to 617°F). |

| Low Coefficient of Friction | Reduces equipment wear, energy consumption, and heat generation. |

| Operational Outcome | Extends service life, reduces maintenance, and protects capital equipment. |

Ready to enhance your equipment's reliability and reduce long-term costs with precision PTFE components?

KINTEK specializes in manufacturing high-performance Teflon (PTFE) seals, gland packing, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution perfectly tailored to your application's demands, including aggressive chemicals and extreme temperatures.

Contact KINTEK today to discuss your specific requirements and invest in lasting operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications