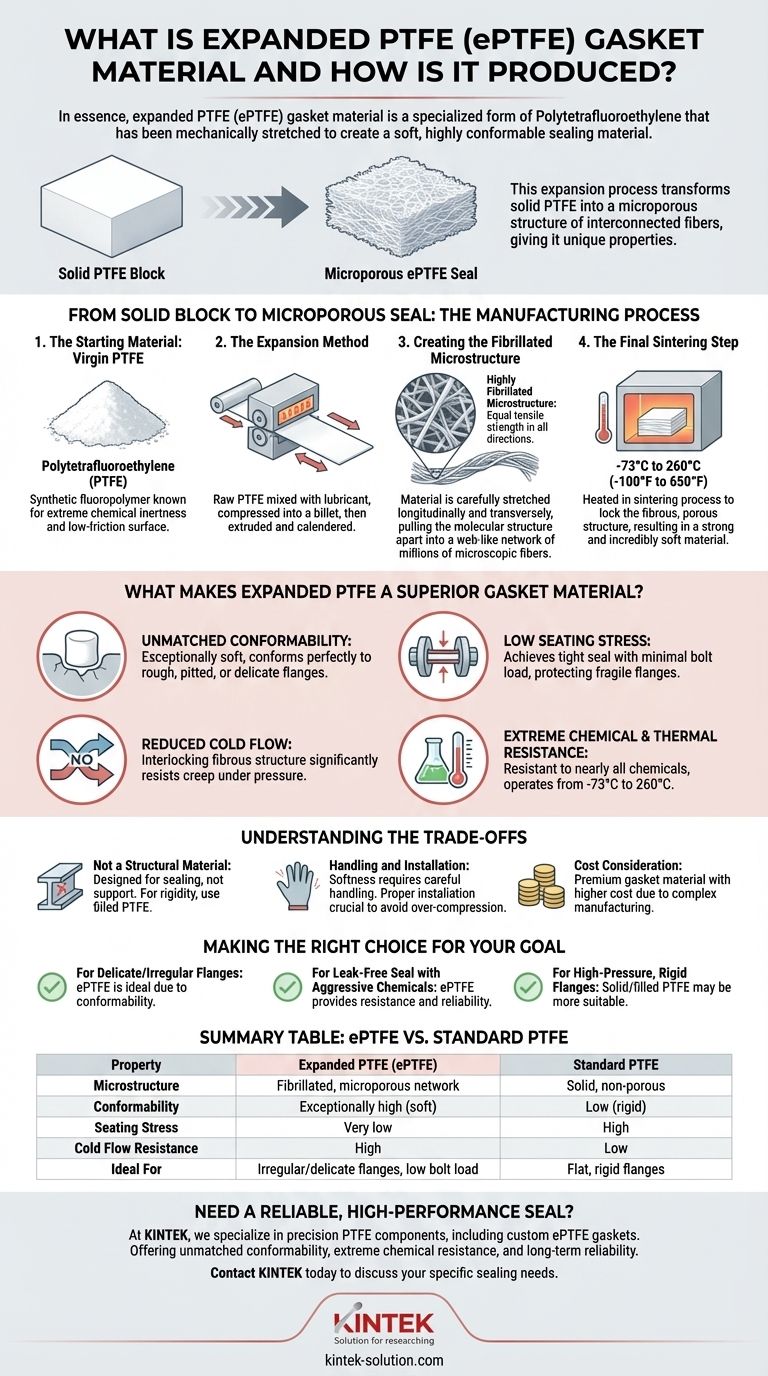

In essence, expanded PTFE (ePTFE) gasket material is a specialized form of Polytetrafluoroethylene that has been mechanically stretched to create a soft, highly conformable sealing material. This expansion process transforms solid PTFE into a microporous structure of interconnected fibers, giving it unique properties that standard PTFE lacks. The manufacturing method involves mixing virgin PTFE with a lubricant, extruding it, and then carefully stretching it in multiple directions before heating it to lock the new structure in place.

The core advantage of expanded PTFE lies not just in the chemical resistance it shares with standard PTFE, but in the unique fibrous microstructure created during its manufacturing. This structure makes it exceptionally soft and conformable, enabling it to create a highly effective seal on irregular surfaces with very little compressive force.

From Solid Block to Microporous Seal: The Manufacturing Process

The unique properties of ePTFE are a direct result of its specialized manufacturing process. It's a multi-step transformation that turns a rigid plastic into a flexible sealing champion.

The Starting Material: Virgin PTFE

The process begins with Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its extreme chemical inertness and low-friction surface, commonly associated with the Teflon™ brand.

The Expansion Method

First, the raw PTFE is mixed with a lubricant and compressed into a solid preform or billet. This billet is then extruded and calendered into a sheet or tape.

The crucial step is the mechanical expansion. The material is carefully stretched, often both longitudinally (in the direction of its length) and transversely (across its width).

Creating the Fibrillated Microstructure

This controlled stretching pulls the PTFE's molecular structure apart, creating a web-like network of millions of microscopic fibers. This is known as a highly fibrillated microstructure.

This process gives the material equal tensile strength in all directions, eliminating the structural weak points or "grain" that can exist in other materials.

The Final Sintering Step

After expansion, the material is heated in a process called sintering. This locks the fibrous, porous structure into place, resulting in a material that is both strong and incredibly soft.

What Makes Expanded PTFE a Superior Gasket Material?

The unique microstructure of ePTFE provides a combination of benefits that make it an ideal choice for challenging sealing applications.

Unmatched Conformability

Described as having a texture like a dense marshmallow, ePTFE is exceptionally soft. This allows it to conform perfectly to rough, pitted, damaged, or irregular flange surfaces, including delicate glass-lined equipment.

Low Seating Stress

Because of its softness, ePTFE can achieve a tight seal with minimal bolt load. This is critical for protecting fragile flanges made of plastic, glass, or other materials that could crack under the high torque required for other gasket types.

Reduced Cold Flow

Standard solid PTFE gaskets can be prone to cold flow, or creep, where the material slowly deforms under pressure, leading to a loss of bolt torque and potential leaks. The interlocking fibrous structure of ePTFE significantly resists this, ensuring a more reliable and long-lasting seal.

Extreme Chemical and Thermal Resistance

ePTFE inherits the remarkable properties of virgin PTFE. It is resistant to nearly all industrial chemicals and can operate across a vast temperature range, typically from -100°F up to 650°F (-73°C to 260°C).

Understanding the Trade-offs

While ePTFE is a high-performance material, it's important to recognize its specific use case. It is an engineered solution, not a universal replacement for all other gasket types.

Not a Structural Material

ePTFE is designed for sealing, not for structural support. Its primary advantage is its softness and conformability. In applications requiring high rigidity or mechanical strength, a filled PTFE gasket (containing materials like fiberglass or carbon) would be more suitable.

Handling and Installation

The material's softness requires careful handling to prevent nicks or damage before it is installed. While it requires low seating stress, proper installation technique is still crucial to avoid over-compression, which can compromise the seal's integrity.

Cost Consideration

The complex, multi-stage manufacturing process makes ePTFE a premium gasket material. Its cost is typically higher than that of more conventional compressed fiber or standard PTFE gaskets.

Making the Right Choice for Your Goal

Selecting the correct gasket material requires matching its properties to the demands of the application.

- If your primary focus is sealing delicate or irregular flanges: ePTFE is the ideal choice due to its exceptional conformability and low required bolt load.

- If your primary focus is ensuring a leak-free seal with aggressive chemicals: ePTFE provides the chemical resistance of solid PTFE but with superior sealing reliability on less-than-perfect surfaces.

- If your primary focus is high-pressure service with rigid, perfectly flat flanges: A solid or filled PTFE gasket may provide the necessary rigidity and be a more cost-effective solution.

By understanding that ePTFE's advantage comes from its unique structure, you can confidently specify it for demanding applications where a perfect, low-stress seal is non-negotiable.

Summary Table:

| Property | Expanded PTFE (ePTFE) | Standard PTFE |

|---|---|---|

| Microstructure | Fibrillated, microporous network | Solid, non-porous |

| Conformability | Exceptionally high (soft) | Low (rigid) |

| Seating Stress | Very low | High |

| Cold Flow Resistance | High | Low |

| Ideal For | Irregular/delicate flanges, low bolt load | Flat, rigid flanges |

Need a reliable, high-performance seal for your most demanding applications?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom ePTFE gaskets. Our expertise ensures you get a sealing solution that offers unmatched conformability, extreme chemical resistance, and long-term reliability—perfect for the semiconductor, medical, laboratory, and industrial sectors.

We handle everything from prototype development to high-volume production, ensuring your specifications are met with the highest quality standards.

Contact KINTEK today to discuss your specific sealing needs and discover how our custom ePTFE solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers