In aerospace and defense systems, Polytetrafluoroethylene (PTFE) is a critical material used for components that demand extreme reliability. It is most commonly found in control surface bearings, sliding joints, seals for aggressive fuel and hydraulic systems, and as high-performance insulation for critical wiring. These applications are chosen specifically because of PTFE's unique combination of properties, including its ability to withstand extreme temperatures and resist chemical corrosion.

PTFE is not chosen for a single benefit, but for its rare combination of low friction, chemical inertness, and thermal stability. This allows it to solve critical engineering challenges in the unforgiving operational environments of aircraft and spacecraft where failure is not an option.

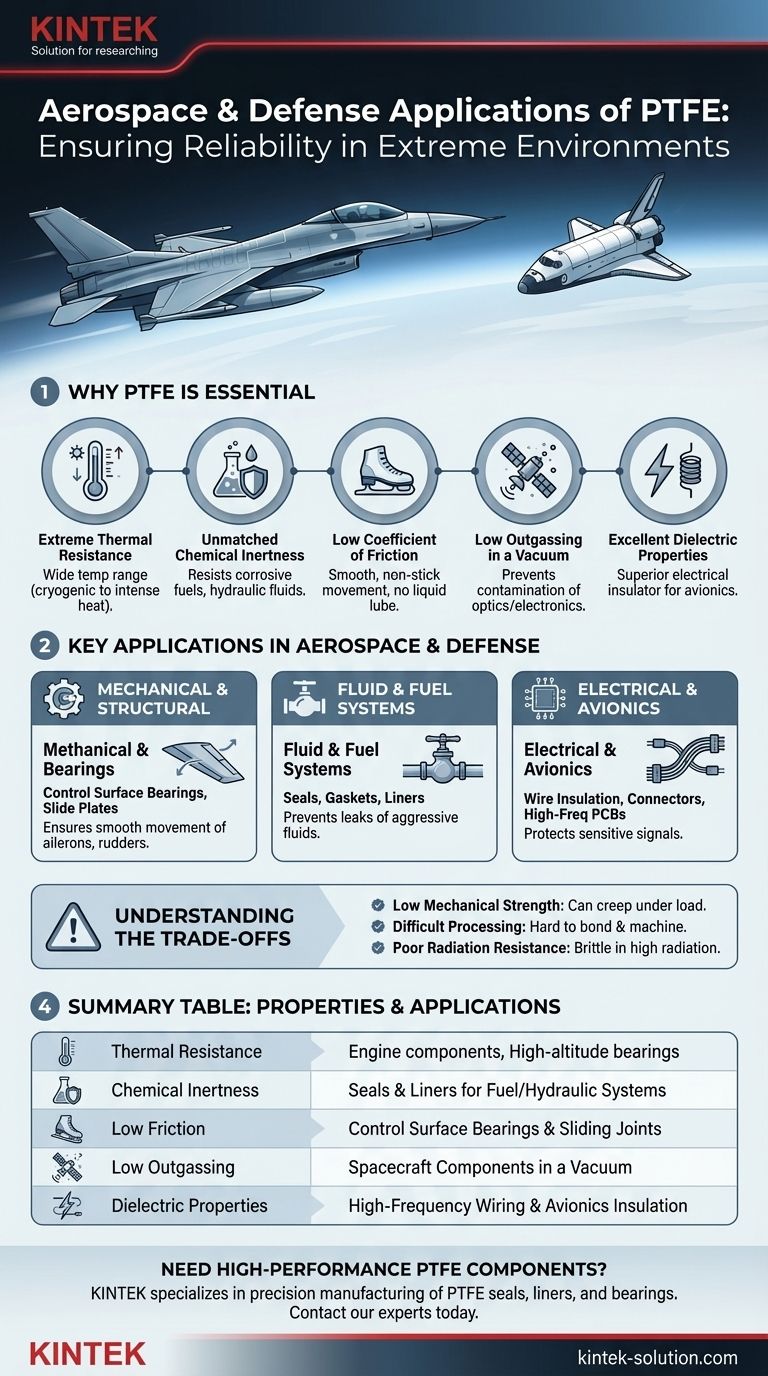

Why PTFE is Essential for High-Stakes Environments

The value of PTFE in aerospace and defense comes from a unique set of material properties that function reliably under extreme stress. Engineers specify this material when performance and safety are the absolute priorities.

Extreme Thermal Resistance

PTFE maintains its integrity across an exceptionally wide temperature range. This is critical for components on aircraft that experience cryogenic temperatures at high altitudes and intense heat from engines or high-speed atmospheric friction.

Unmatched Chemical Inertness

Aerospace systems rely on aggressive hydraulic fluids, corrosive fuels, and powerful oxidizing agents. PTFE is nearly immune to all of them, making it the ideal choice for liners, seals, and gaskets that prevent leaks and system degradation.

Exceptionally Low Coefficient of Friction

Known for its "non-stick" quality, PTFE has one of the lowest coefficients of friction of any solid. This property is essential for components like bearings and sliding joints, allowing flight control surfaces to move smoothly and reliably without the need for liquid lubricants that could fail at extreme temperatures.

Low Outgassing in a Vacuum

In the vacuum of space, some materials release trapped gases in a process called outgassing. These released molecules can contaminate sensitive optical instruments and electronics. PTFE has very low outgassing characteristics, making it a trusted material for spacecraft components.

Excellent Dielectric Properties

PTFE is an outstanding electrical insulator. It is used for high-performance wire and cable insulation in avionics systems, protecting sensitive signals from interference and preventing electrical shorts in compact, high-density electronic packages.

Key Applications in Aerospace and Defense Systems

These fundamental properties translate directly into specific, high-value applications where other materials would quickly fail.

Mechanical and Structural Components

PTFE is machined into plain bearings, slide plates, and washers. These parts are used in the joints of flight control surfaces like ailerons, rudders, and flaps, ensuring they move with minimal resistance and wear over thousands of hours of operation.

Fluid and Fuel Systems

The material is fabricated into seals, gaskets, valve seats, and liners for fuel and hydraulic lines. Its chemical resistance ensures the integrity of these systems, preventing dangerous leaks of flammable or corrosive fluids.

Electrical and Avionics Systems

As a superior insulator, PTFE is used to coat wiring and fabricate connectors for critical avionics. It is also used as a substrate material for printed circuit boards (PCBs) that operate at high frequencies, ensuring signal integrity for radar and communication systems.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. It is a specialized polymer with clear limitations that engineers must account for.

Low Mechanical Strength

Compared to metals or other engineering plastics, PTFE is relatively soft and has low tensile strength. It can deform or "creep" under a sustained load, making it unsuitable for primary structural applications.

Difficulty in Processing

PTFE's chemical inertness and non-stick surface make it very difficult to bond to other materials using conventional adhesives. It also requires specialized techniques for machining and molding.

Poor Radiation Resistance

In certain high-radiation environments, such as long-duration space missions outside Earth's magnetosphere, PTFE can become brittle and degrade. In these cases, engineers must specify radiation-hardened materials or provide adequate shielding.

Making the Right Choice for Your Goal

Selecting PTFE is a decision driven by a specific engineering need. Its value is highest where environmental challenges would compromise lesser materials.

- If your primary focus is reliable mechanical movement: PTFE is the optimal choice for low-friction bearings and joints that must operate without external lubrication across wide temperature swings.

- If your primary focus is fluid containment and system integrity: Its unparalleled chemical inertness makes it essential for seals, gaskets, and liners in aggressive fuel or hydraulic systems.

- If your primary focus is avionics and electrical performance: Its excellent dielectric properties and thermal stability are critical for high-frequency wiring, connectors, and circuit boards.

Ultimately, PTFE's value in aerospace and defense lies in its ability to deliver consistent, predictable performance in applications where reliability is paramount.

Summary Table:

| Key Property | Key Aerospace/Defense Application |

|---|---|

| Extreme Thermal Resistance | Engine components, high-altitude bearings |

| Chemical Inertness | Seals & liners for fuel/hydraulic systems |

| Low Friction | Control surface bearings & sliding joints |

| Low Outgassing | Spacecraft components in a vacuum |

| Excellent Dielectric Properties | High-frequency wiring & avionics insulation |

Need high-performance PTFE components for your critical aerospace or defense project? KINTEK specializes in the precision manufacturing of PTFE seals, liners, bearings, and custom labware. We understand the extreme demands of the semiconductor, medical, and specialized industrial sectors. From prototypes to high-volume orders, our custom fabrication ensures the reliability your applications demand. Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions