In essence, PTFE packing is the default sealing solution for dynamic equipment like pumps and valves operating in chemically aggressive or high-purity environments. Its use spans industries from petrochemical and manufacturing to pharmaceuticals and food processing, where it creates a robust seal against highly corrosive substances, protects product purity, and minimizes wear on mechanical components.

While its applications are diverse, the core reason for choosing PTFE packing is its near-universal chemical inertness. This property makes it the default choice for sealing equipment that handles aggressive chemicals or requires absolute purity, with only a few specific exceptions.

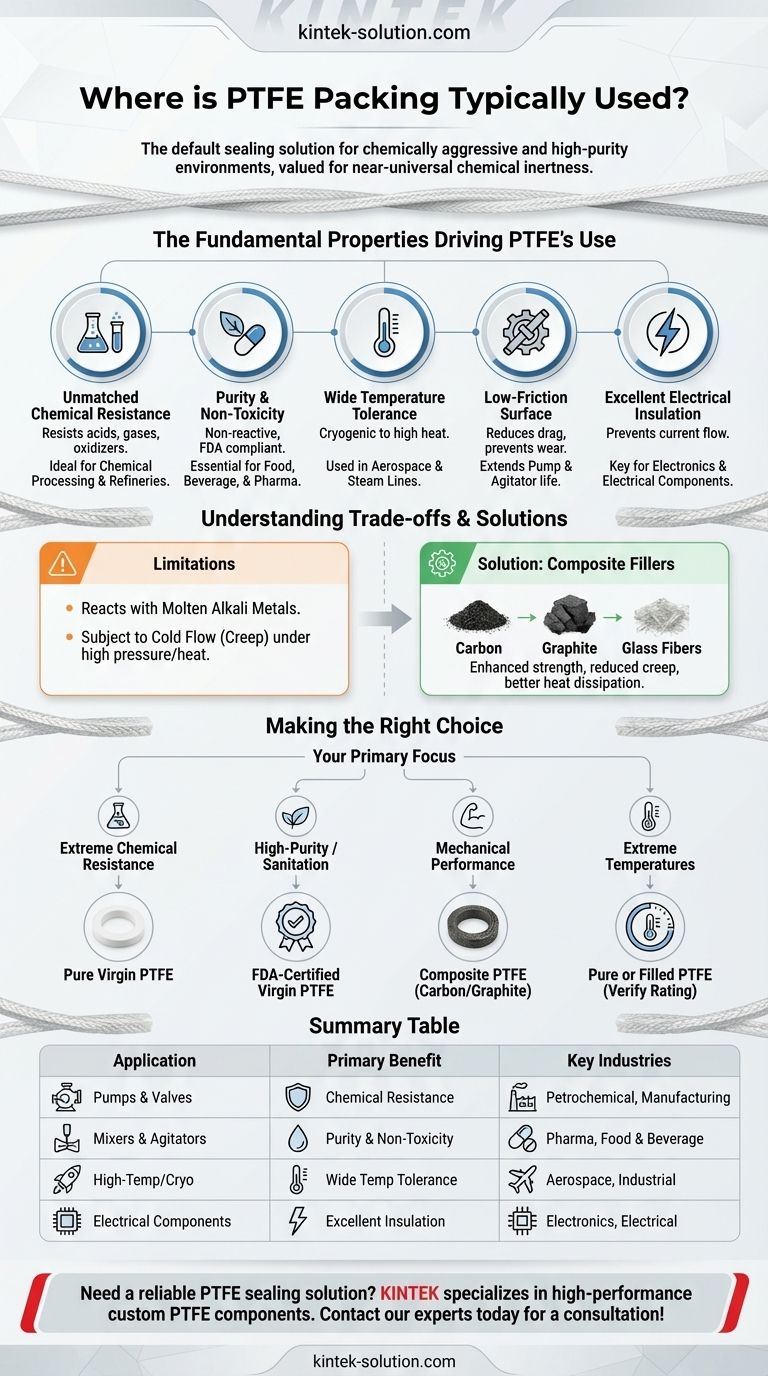

The Fundamental Properties Driving PTFE's Use

To understand where PTFE packing is used, you must first understand its core characteristics. Its applications are a direct result of a unique combination of properties that few other materials can offer.

Unmatched Chemical Resistance

This is the primary reason PTFE is specified in so many demanding applications. It is exceptionally resistant to almost all industrial chemicals, acids, gases, and strong oxidizers.

This makes it indispensable for equipment in chemical processing plants, refineries, and any system handling corrosive media. The material simply does not react, ensuring the integrity of both the seal and the substance being transported.

Purity and Non-Toxicity

PTFE can be manufactured to an extremely high level of purity. It is non-toxic, non-reactive, and can meet stringent FDA requirements for materials in contact with consumables.

This property makes it a cornerstone of the food, beverage, and pharmaceutical industries. It is used to seal mixers, pumps, and valves, guaranteeing that the product remains sterile and uncontaminated.

Wide Temperature Tolerance

PTFE packing maintains its integrity across an exceptionally broad temperature range, from cryogenic applications to high-temperature services.

This versatility allows it to be used in specialized fields like aerospace, where components face extreme temperature swings, and in industrial plants for sealing lines carrying steam or other high-temperature fluids.

Low-Friction and Anti-Wear Surface

PTFE has one of the lowest coefficients of friction of any solid material. When braided into packing, this low-friction surface reduces drag and prevents wear on rotating shafts and valve stems.

This significantly extends the life of expensive equipment like pumps and agitators by providing a smooth, protective, and durable sealing surface.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator, which makes it a valuable material in the electrical and electronics industries.

It is commonly used for high-quality wire insulation, gaskets in transformers, and other components where preventing electrical current flow is critical.

Understanding the Trade-offs and Limitations

No material is perfect. While incredibly versatile, PTFE has specific limitations that are crucial to understand for proper application. An expert knows not only what a material can do, but also what it cannot.

Resistance to Molten Alkali Metals

The most well-documented exception to PTFE's chemical resistance is its reactivity with molten alkali metals (like sodium and potassium) and certain rare fluorochemicals. In these specific, high-temperature scenarios, PTFE is not a suitable choice.

Cold Flow (Creep)

Under sustained high pressure, especially at elevated temperatures, pure PTFE can be susceptible to "creep" or "cold flow." This is a slow deformation of the material that can eventually compromise the seal.

This is a critical consideration in high-load static sealing applications. The effect is often managed by selecting the correct packing density and installation procedure.

The Role of Fillers and Composites

To counteract mechanical limitations like creep, PTFE is often blended with other materials. Fillers like carbon, graphite, or glass fibers are added to the PTFE before it is braided into packing.

These composite packings offer enhanced mechanical strength, better heat dissipation, and improved resistance to wear and extrusion, while still retaining most of the base PTFE's excellent chemical resistance.

Making the Right Choice for Your Application

Selecting the correct packing material is a critical engineering decision. Your choice should be dictated by the primary demand of the system you are designing or maintaining.

- If your primary focus is extreme chemical resistance: Pure, virgin PTFE packing is the safest and most reliable choice for handling the widest range of aggressive media.

- If your primary focus is high-purity or sanitation: You must use a virgin PTFE packing that is explicitly certified for FDA, USDA, or other relevant standards for food or pharmaceutical contact.

- If your primary focus is mechanical performance (e.g., high pressure or shaft speed): Consider a composite PTFE packing filled with carbon or graphite to improve strength, reduce creep, and dissipate heat more effectively.

- If your primary focus is sealing in extreme temperatures: Both pure and filled PTFE packings are excellent choices, but you must verify the specific temperature rating of the product you select.

By understanding these core properties and trade-offs, you can confidently determine when PTFE packing is not just an option, but the optimal engineering solution for your goal.

Summary Table:

| Application | Primary Benefit | Key Industries |

|---|---|---|

| Pumps & Valves | Chemical Resistance | Petrochemical, Manufacturing |

| Mixers & Agitators | Purity & Non-Toxicity | Pharmaceutical, Food & Beverage |

| High-Temp/Cryogenic Systems | Wide Temperature Tolerance | Aerospace, Industrial |

| Electrical Components | Excellent Insulation | Electronics, Electrical |

Need a reliable PTFE sealing solution for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom packing, seals, and liners. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal that meets the exact demands of your environment.

Let us help you enhance equipment longevity and protect your processes. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications