For long-term industrial applications, PTFE lined butterfly valves offer a powerful combination of durability, reduced maintenance requirements, and superior chemical resistance. This results in a significantly longer service life and lower overall cost of ownership compared to many alternatives, especially in harsh operating environments.

The core benefit of a PTFE lined butterfly valve isn't just one feature, but how its unique properties—chemical inertness, a non-stick surface, and wide temperature tolerance—work together to create a highly reliable, low-maintenance component that enhances system safety and long-term financial efficiency.

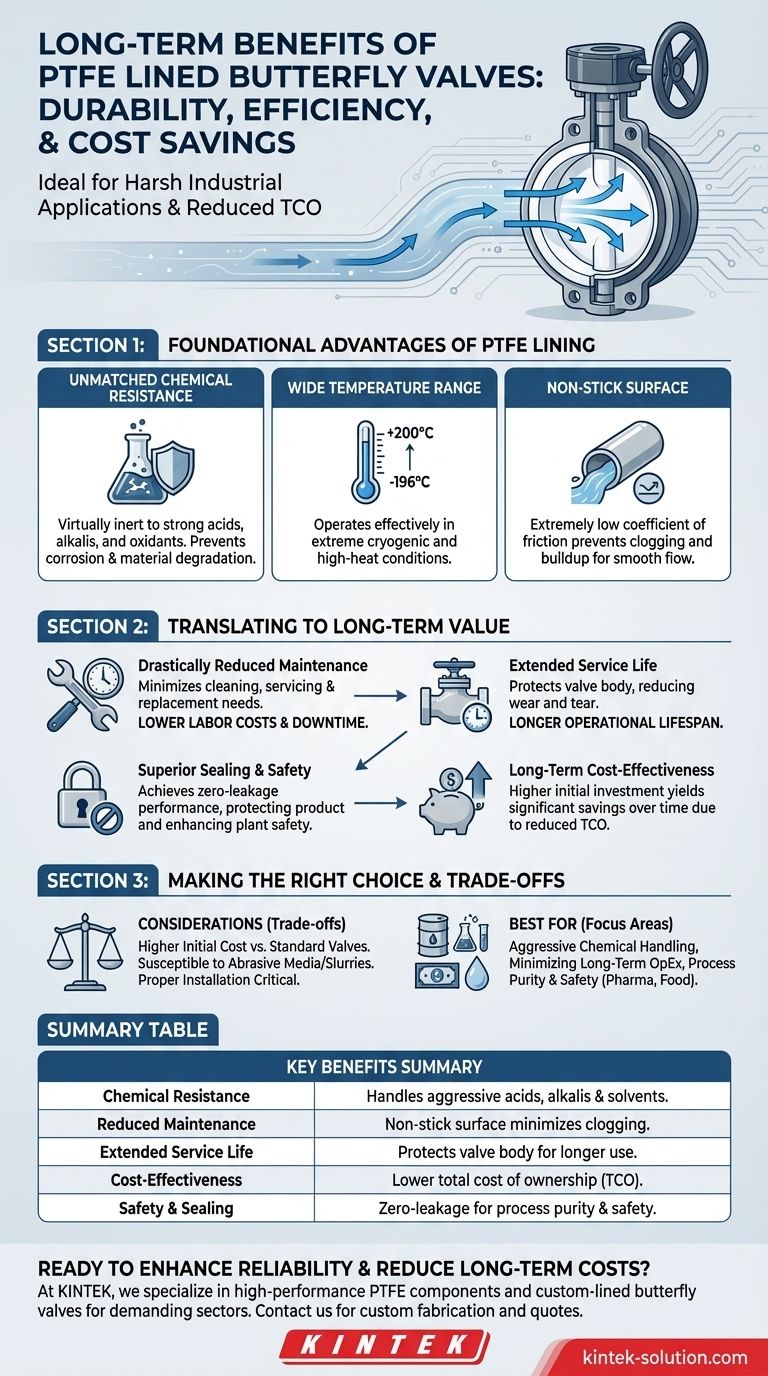

The Foundational Advantages of PTFE Lining

To understand the long-term value, we first need to look at the inherent properties of Polytetrafluoroethylene (PTFE) itself. This material is the source of the valve's robust performance.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals, including strong acids, alkalis, and oxidants. This makes it an ideal choice for systems handling aggressive or corrosive media that would quickly degrade other materials.

Wide Operational Temperature Range

These valves demonstrate excellent thermal stability. They can operate effectively in extreme conditions, with a functional range from cryogenic temperatures (-196°C) up to high temperatures of 200°C or more.

The Power of a Non-Stick Surface

PTFE has an extremely low coefficient of friction. This non-stick quality is critical, as it prevents media from adhering to the valve's internal surfaces, ensuring a smooth flow and preventing clogging or material buildup.

Translating Properties into Long-Term Value

The foundational properties of PTFE directly translate into tangible, long-term operational and financial benefits for your facility.

Drastically Reduced Maintenance

Because the PTFE liner resists both chemical attack and material buildup, the need for routine cleaning, servicing, and component replacement is significantly minimized. This leads to less downtime and lower labor costs over the valve's life.

Extended Service Life

The liner protects the valve body from the process media, preventing corrosion and minimizing wear and tear on critical components. This protection results in a much longer operational lifespan compared to unlined or less-resistant valves.

Superior Sealing and Safety

PTFE lined valves are engineered for high sealing performance, often achieving zero-leakage specifications. This prevents the loss of valuable product and, more importantly, enhances plant safety by containing potentially hazardous substances.

Long-Term Cost-Effectiveness

While the initial investment might be higher than some alternatives, the savings from reduced maintenance, prevented downtime, and longer replacement cycles make PTFE lined valves a more cost-effective choice over the long term.

Understanding the Trade-offs

No component is perfect for every situation. Objectivity requires acknowledging the potential limitations.

Initial Cost Considerations

Valves with a high-performance PTFE lining typically have a higher upfront cost than standard valves with EPDM or other rubber liners. This initial expense must be weighed against the long-term savings.

Susceptibility to Abrasives

While chemically robust, PTFE liners can be susceptible to mechanical damage from highly abrasive slurries or sharp particulates in the media. In such cases, a different valve type or a more specialized liner may be required.

Proper Installation is Critical

The integrity of the liner is paramount. Improper installation, such as over-torquing flange bolts, can damage the liner and compromise the valve's sealing capability and lifespan.

Making the Right Choice for Your System

Selecting the right valve depends entirely on your primary operational goal.

- If your primary focus is handling aggressive chemicals: A PTFE lined valve is the definitive choice for its unmatched corrosion resistance.

- If your primary focus is minimizing long-term operating costs: The combination of low maintenance and extended lifespan makes this valve a sound financial investment.

- If your primary focus is process purity and safety: The non-stick surface and zero-leakage potential are ideal for applications in pharmaceuticals, food processing, and water treatment.

Ultimately, choosing a PTFE lined butterfly valve is an investment in the long-term reliability and efficiency of your entire system.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Resistance | Handles aggressive acids, alkalis, and solvents, preventing corrosion. |

| Reduced Maintenance | Non-stick surface minimizes clogging and lowers cleaning frequency. |

| Extended Service Life | Protects valve body, leading to longer operational lifespan. |

| Cost-Effectiveness | Lower total cost of ownership despite a higher initial investment. |

| Safety & Sealing | Achieves zero-leakage performance for process purity and safety. |

Ready to enhance your system's reliability and reduce long-term costs?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-lined butterfly valves for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your valves meet the highest standards for chemical resistance and durability.

Whether you need a prototype or a high-volume order, we provide custom fabrication to fit your exact specifications.

Contact us today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do PTFE expansion joints contribute to sustainability? Enhance Long-Term System Integrity & Environmental Safety

- What is the role of PTFE backup rings in sealing applications? Prevent Seal Extrusion Under High Pressure

- How do stainless steel impellers compare to PTFE impellers in terms of non-stick properties? Prevent Residue & Buildup

- Why choose PTFE V-Ring seals? Unmatched Reliability for Extreme Conditions

- What are the advantages of oil-impregnated PTFE gland packing? Superior Sealing for Harsh and Sanitary Applications

- In which industries are PTFE gaskets commonly used? Ensuring Safety & Purity in Demanding Applications

- Why are extruded PTFE rods suitable for high-temperature applications? Superior Heat Resistance for Demanding Industries

- Why are PTFE ball valves not recommended for slurries? Prevent Abrasive Damage and Valve Failure