At its core, the chemical resistance of Polytetrafluoroethylene (PTFE) is significant for shaft seals because it guarantees the seal will not degrade when exposed to aggressive media. Its unique molecular structure makes it nearly inert, preventing chemical attacks that would cause other materials to swell, harden, or dissolve, which would inevitably lead to seal failure, leaks, and equipment damage.

In environments where exposure to acids, solvents, or corrosive chemicals is a constant, a seal’s material integrity is paramount. PTFE’s exceptional chemical resistance is not just a feature; it is the fundamental property that ensures operational reliability and longevity where conventional seals would quickly fail.

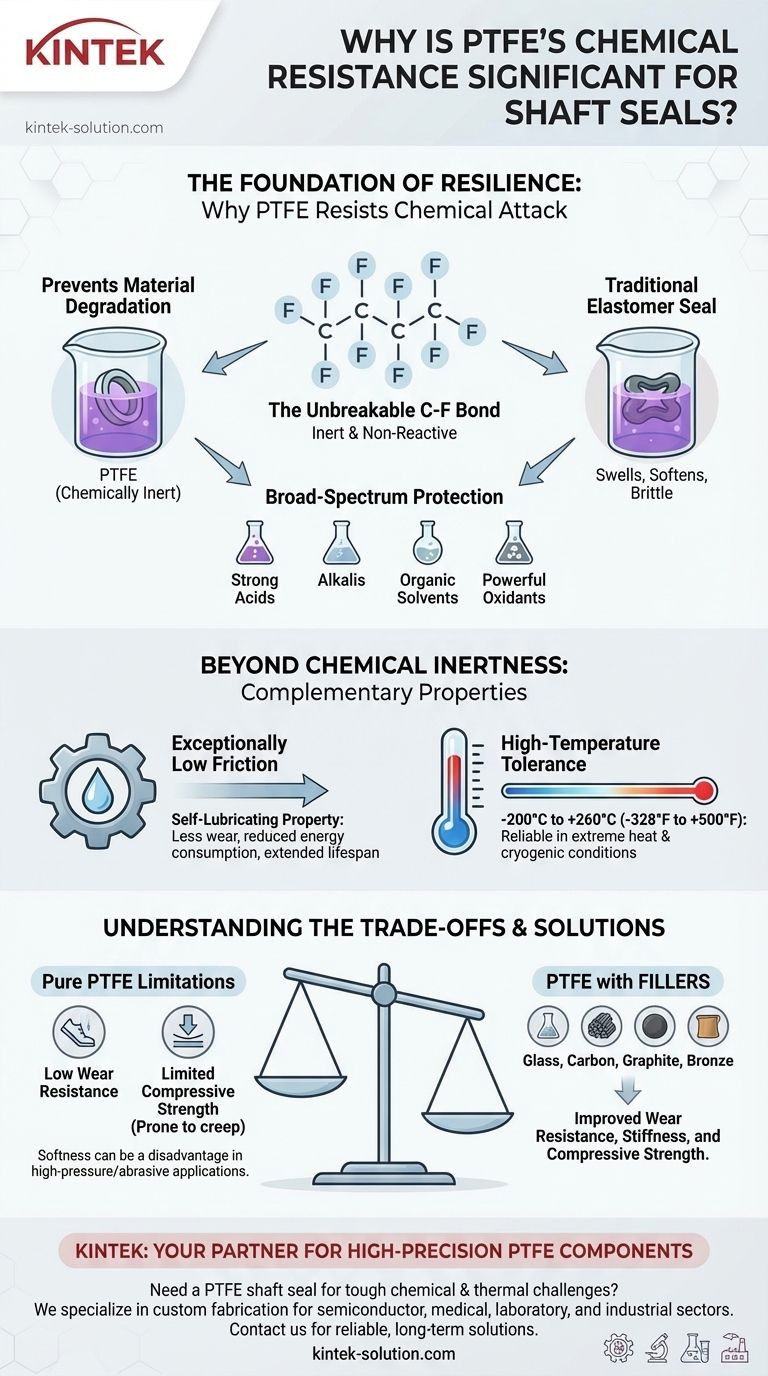

The Foundation of Resilience: Why PTFE Resists Chemical Attack

The remarkable performance of PTFE in harsh environments is not accidental; it is a direct result of its unique molecular structure. This structure provides a level of stability that few other polymers can match.

The Unbreakable Carbon-Fluorine Bond

PTFE's backbone consists of a chain of carbon atoms completely shielded by a sheath of fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry.

This powerful bond makes the molecule incredibly stable and non-reactive, rendering it inert to almost all industrial chemicals and solvents.

Preventing Material Degradation

When traditional elastomer seals are exposed to incompatible chemicals, they can swell, soften, or become brittle. This physical change compromises the seal's ability to maintain its intended shape and pressure against the shaft.

Because PTFE is chemically inert, it maintains its physical properties and structural integrity, ensuring a consistent, leak-free seal over its entire service life.

Broad-Spectrum Protection

PTFE's inertness is not limited to a narrow range of substances. It provides reliable sealing against a vast array of aggressive media.

This includes strong acids, alkalis, organic solvents, and powerful oxidants, making it a highly versatile solution for the chemical processing, pharmaceutical, and manufacturing industries.

Beyond Chemical Inertness: Complementary Properties

While chemical resistance is the headline feature, several other inherent properties of PTFE make it an ideal material for dynamic sealing applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property minimizes heat generation at the contact point.

This results in less wear on both the seal and the shaft, reduces energy consumption, and significantly extends the operational lifespan of the components.

High-Temperature Tolerance

PTFE seals can operate across an extremely wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability allows them to perform reliably in applications involving extreme heat or cryogenic conditions, where many other materials would become brittle or degrade.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's chemical and thermal properties are outstanding, it's critical to understand its mechanical limitations.

The Challenge of Wear Resistance

Virgin (unfilled) PTFE has relatively low resistance to wear and abrasion. Its softness can be a disadvantage in applications with high pressures or contact with hard, rough surfaces.

Limited Compressive Strength

Pure PTFE can be prone to creep or deformation under a constant load, especially at elevated temperatures. This limits its use in high-pressure sealing applications unless it is properly reinforced.

The Role of Fillers

To overcome these mechanical weaknesses, PTFE is often compounded with fillers like glass, carbon, graphite, or bronze. These additives dramatically improve wear resistance, stiffness, and compressive strength while retaining the base material's excellent chemical, thermal, and frictional properties.

Making the Right Choice for Your Application

Selecting the correct seal material requires matching its properties to the demands of the operating environment.

- If your primary focus is sealing aggressive chemicals: PTFE's near-universal chemical inertness makes it the safest and most reliable choice to prevent leaks and protect equipment.

- If your primary focus is high-temperature or cryogenic service: PTFE's exceptional thermal stability ensures consistent performance where other materials would fail.

- If your primary focus is minimizing friction and energy loss: The low-friction, self-lubricating nature of PTFE extends the life of rotating equipment and improves efficiency.

- If your application involves high pressure or abrasive media: Pure PTFE is likely insufficient; you must specify a filled PTFE compound designed for enhanced mechanical duty.

By understanding both its profound strengths and its inherent limitations, you can leverage PTFE to ensure the long-term integrity and efficiency of your critical equipment.

Summary Table:

| Key Property | Benefit for Shaft Seals |

|---|---|

| Chemical Inertness | Resists degradation from acids, alkalis, and solvents |

| Low Friction | Reduces wear and energy consumption |

| High-Temperature Tolerance | Operates from -200°C to +260°C |

| Versatility | Suitable for chemical, pharmaceutical, and industrial uses |

Need a PTFE shaft seal that stands up to your toughest chemical and thermal challenges? KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your equipment operates reliably and efficiently. Contact us today to discuss your specific requirements and leverage our expertise in material science and precision production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials