The primary advantages of Teflon washers stem from their exceptionally low friction, chemical inertness, and durability. These properties make them a highly reliable and low-maintenance component for applications involving moving parts or exposure to harsh environments, as they reduce wear, prevent corrosion, and operate smoothly without external lubricants.

At its core, Teflon's value lies in its unique ability to be both durable and incredibly slippery. This combination solves the persistent engineering challenge of minimizing friction and wear between components, especially in conditions where traditional lubrication is impractical or undesirable.

The Core Properties of Teflon (PTFE) Washers

To understand the advantages of Teflon washers, we must first look at the inherent properties of the material itself, Polytetrafluoroethylene (PTFE).

Exceptionally Low Friction

A Teflon washer's most notable characteristic is its extremely low coefficient of friction. It is one of the most slippery solid materials known.

This property allows moving parts to operate with minimal resistance. This reduces the energy needed for movement and, most importantly, minimizes wear and tear on the components it separates.

Superior Chemical and Corrosion Resistance

Teflon is chemically inert, meaning it does not react with most chemicals. This makes Teflon washers an ideal choice for use in chemical handling systems or other corrosive environments.

Furthermore, its resistance to water prevents rust and corrosion that would degrade metal washers over time, ensuring a longer lifespan for the entire assembly.

Impressive Durability and Wear Resistance

Despite its softness, Teflon is highly durable and abrasion-resistant. It is not easily compressed under typical loads, making it suitable for dynamic applications.

This resilience allows it to function effectively as a barrier between moving parts, such as the blade and handle of a folding knife, without quickly degrading.

Electrical Insulation and Temperature Stability

Teflon is an excellent electrical insulator, making it valuable in electronics and electrical applications where preventing conductivity is critical.

It also maintains its core properties across a range of temperatures, performing particularly well in low-temperature applications where other materials might become brittle.

Practical Advantages in Real-World Applications

These material properties translate directly into tangible benefits across a wide range of industries, from aerospace to food processing.

Low-Maintenance Operation

Because Teflon is naturally self-lubricating, assemblies using Teflon washers often require no external lubricant.

This makes them perfect for "field use" applications where parts may be exposed to dirt, dust, or water, as they will continue to function smoothly even after being washed or splashed.

Protection of Mating Surfaces

Compared to harder materials like phosphor bronze washers, the relative softness of Teflon causes significantly less wear on adjacent metal surfaces.

This prolongs the life of more expensive and critical components by sacrificing the easily replaceable washer instead of the part itself.

Versatile Sealing Capabilities

The flexibility of Teflon allows it to conform to surfaces, creating a tight and reliable seal. This is crucial in plumbing and fluid-handling systems.

Combined with its chemical resistance, this makes it a superior choice for creating gaskets and seals that will not degrade when exposed to various fluids.

Understanding the Trade-offs

No material is perfect for every situation. To make an informed decision, it's critical to understand the limitations of Teflon.

Susceptibility to "Creep"

While not easily compressed in the short term, Teflon can be susceptible to "creep," which is the tendency of a material to deform permanently under a sustained load.

For high-pressure, static applications, this deformation could lead to a loss of bolt preload or sealing pressure over time.

Temperature Ceilings

While excellent for cold environments, standard PTFE has a relatively low melting point compared to metals. Its performance can begin to degrade at higher temperatures.

For applications involving significant heat, other materials like metal or specialized high-temperature polymers may be a more appropriate choice.

Relative Softness

The same softness that protects metal surfaces can also be a disadvantage. In applications with sharp edges or high point loads, a Teflon washer may be more prone to being cut or deformed than a metal alternative.

Making the Right Choice for Your Goal

Ultimately, the decision to use a Teflon washer depends entirely on the demands of your specific application.

- If your primary focus is reducing friction in moving parts: Teflon is an exceptional choice, providing a smooth, self-lubricating action that protects components.

- If your primary focus is sealing against chemicals or moisture: Teflon's inertness and water resistance make it one of the most reliable and long-lasting options available.

- If your primary focus is high-load structural support: Carefully evaluate the potential for creep and consider a harder material if the assembly is subject to high, sustained pressure.

Teflon washers offer a powerful and versatile solution for countless engineering challenges, ensuring efficiency and reliability wherever friction and corrosion must be overcome.

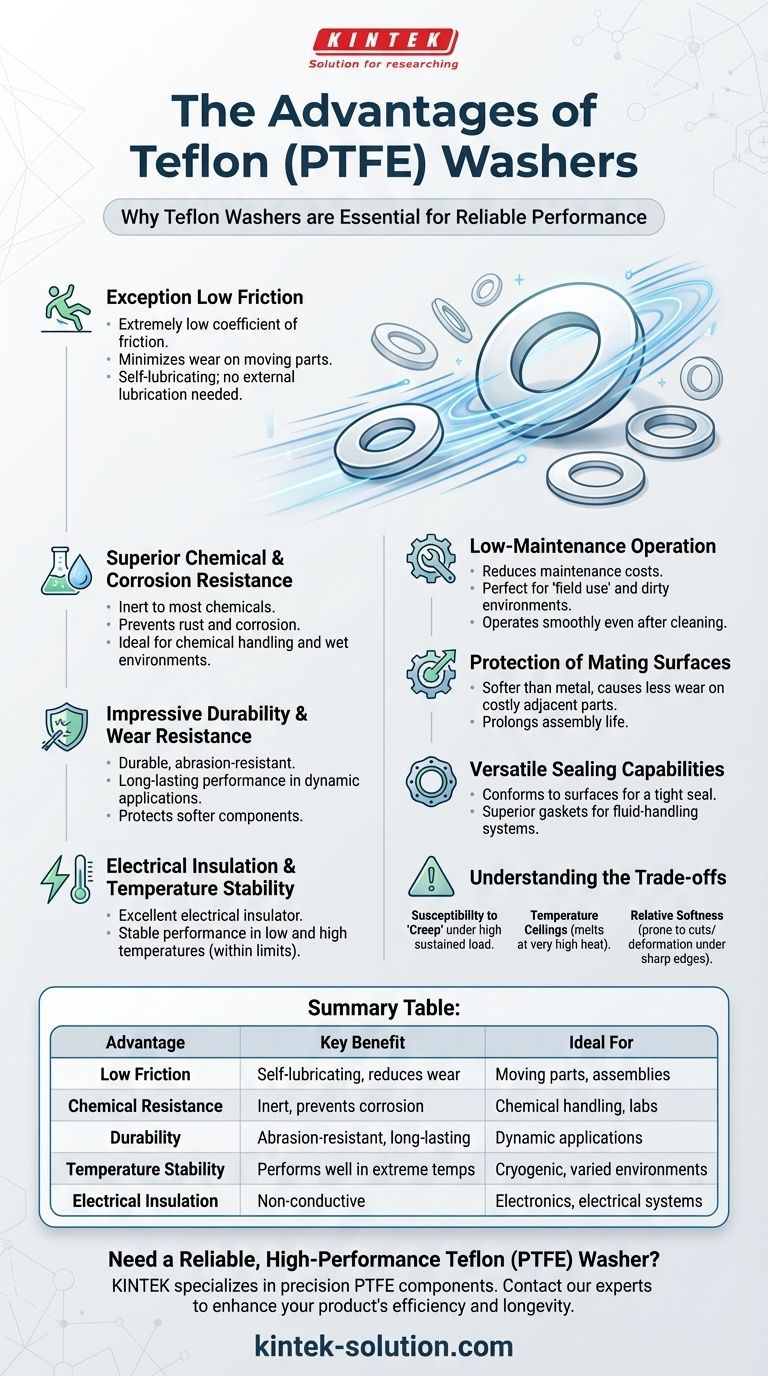

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Low Friction | Self-lubricating, reduces wear | Moving parts, assemblies |

| Chemical Resistance | Inert to most chemicals, prevents corrosion | Chemical handling, labs |

| Durability | Abrasion-resistant, long-lasting | Dynamic applications |

| Temperature Stability | Performs well in low temperatures | Cryogenic, varied environments |

| Electrical Insulation | Non-conductive | Electronics, electrical systems |

Need a reliable, high-performance Teflon (PTFE) washer for your application?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services ensure you get the exact washer you need, from prototypes to high-volume orders.

Let us help you enhance your product's efficiency and longevity. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments