In the world of aerospace engineering, Polytetrafluoroethylene (PTFE) seals are indispensable components found in the most critical systems. They are specified for actuators, turbine engines, gearboxes, landing gear, fuel systems, and cryogenic valves. Their deployment extends across both commercial and military aircraft in applications ranging from Auxiliary Power Units (APUs) to high-speed alternators and brake systems.

The core reason PTFE seals are ubiquitous in aerospace is not just their versatility, but their fundamental ability to maintain integrity under extreme conditions. They are engineered solutions for high-speed, high-temperature, and chemically aggressive environments where traditional elastomeric seals would inevitably fail.

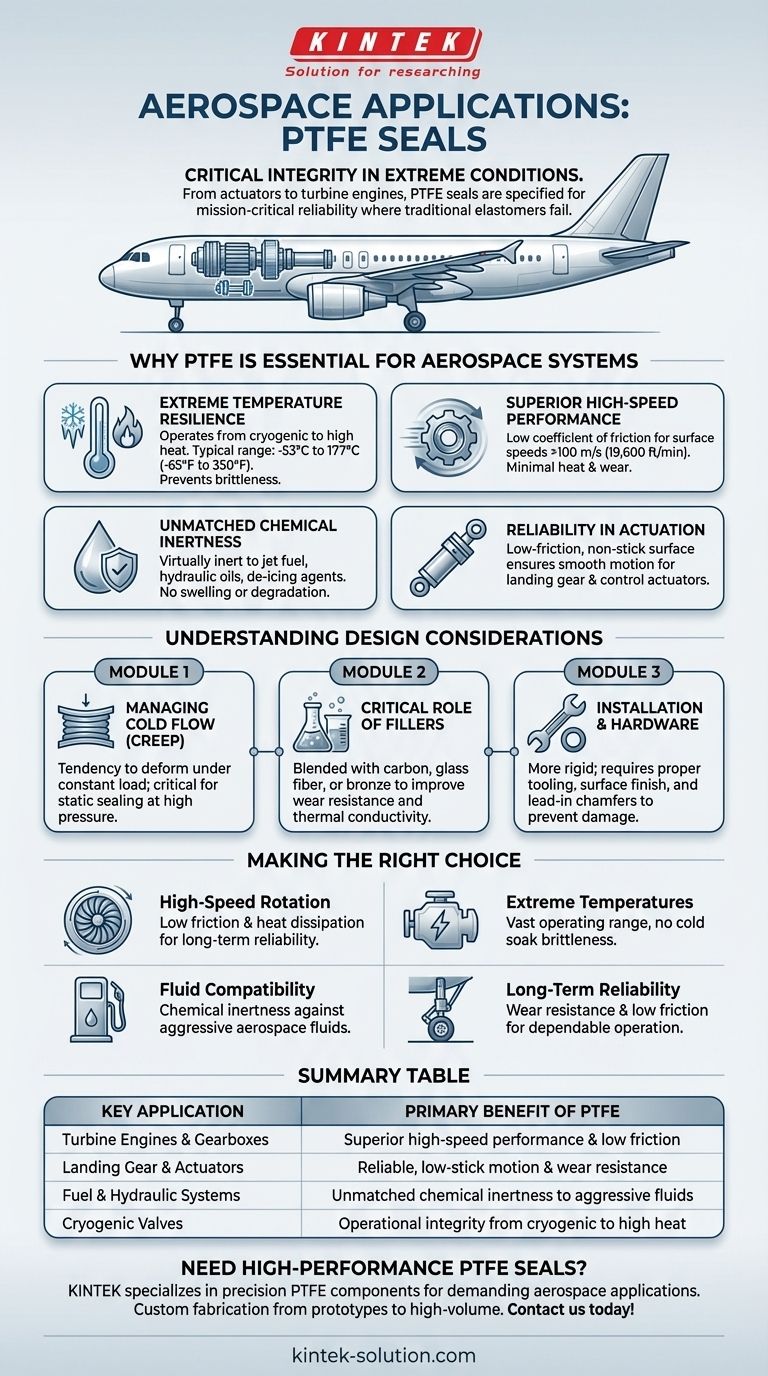

Why PTFE is Essential for Aerospace Systems

The selection of a sealing material in aerospace is a matter of mission-critical reliability. PTFE's unique combination of properties makes it the default choice for applications that push the boundaries of performance.

Extreme Temperature Resilience

PTFE seals operate reliably across an exceptionally wide thermal range, from cryogenic applications to the high heat of engine compartments.

They maintain their properties in typical aerospace operating windows of -53°C to 177°C (-65°F to 350°F), preventing the brittleness or degradation that affects other materials.

Superior High-Speed Performance

Many aerospace systems involve high-speed rotating shafts, such as in turbines, gearboxes, and pumps.

PTFE's extremely low coefficient of friction allows it to handle surface speeds exceeding 100 m/s (19,600 ft/min), generating minimal heat and wear where an elastomer seal would quickly burn up.

Unmatched Chemical Inertness

Aerospace systems expose components to a variety of aggressive fluids, including jet fuel, hydraulic oils, and de-icing agents.

PTFE is virtually inert to all of these chemicals. This prevents the seal from swelling, softening, or degrading over time, ensuring a consistent and reliable seal for the life of the component.

Reliability in Actuation and Control

Systems like landing gear and flight control actuators demand smooth, reliable motion without sticking or seizing.

The low-friction, non-stick surface of PTFE ensures consistent performance, while its wear resistance provides the long service life required for these critical safety systems.

Understanding the Trade-offs and Design Considerations

While highly capable, PTFE is not a universal solution. Effective implementation requires understanding its material properties and limitations.

Managing Cold Flow (Creep)

The primary limitation of pure PTFE is its tendency to "cold flow," or deform over time when under a constant load.

This is a critical design consideration, especially in static sealing applications under high pressure.

The Critical Role of Fillers

To counteract creep and enhance other properties, virgin PTFE is rarely used alone in demanding applications.

It is typically blended with fillers like carbon, glass fiber, or bronze. These additives dramatically improve wear resistance, thermal conductivity, and resistance to deformation, tailoring the seal's performance to the specific application.

Installation and Hardware Design

PTFE seals are generally more rigid than their elastomer counterparts and can be more sensitive to installation procedures.

Proper tooling and careful handling are necessary to prevent damage. Furthermore, the hardware design, including surface finish and lead-in chamfers, is critical to ensuring the seal's long-term effectiveness.

Making the Right Choice for Your Application

Selecting the correct seal is about matching the material's strengths to the specific demands of the system.

- If your primary focus is high-speed rotation (turbines, gearboxes): PTFE's low friction and ability to dissipate heat make it the only viable choice for long-term reliability.

- If your primary focus is extreme temperatures (cryogenic valves, engine compartments): PTFE's vast operating temperature range ensures it will not become brittle at cold soak or degrade in high heat.

- If your primary focus is fluid compatibility (fuel pumps, hydraulic systems): The chemical inertness of PTFE guarantees seal integrity against aggressive aerospace fluids.

- If your primary focus is long-term reliability in actuation (landing gear, flaps): The combination of wear resistance and low friction ensures smooth, dependable operation over thousands of cycles.

Ultimately, specifying a PTFE seal is a strategic engineering decision to ensure operational integrity under the most unforgiving conditions.

Summary Table:

| Key Application | Primary Benefit of PTFE |

|---|---|

| Turbine Engines & Gearboxes | Superior high-speed performance & low friction |

| Landing Gear & Actuators | Reliable, low-stick motion & wear resistance |

| Fuel & Hydraulic Systems | Unmatched chemical inertness to aggressive fluids |

| Cryogenic Valves | Operational integrity from cryogenic to high heat |

Need high-performance PTFE seals for your aerospace applications? KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders, ensuring your systems perform reliably under extreme conditions. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance