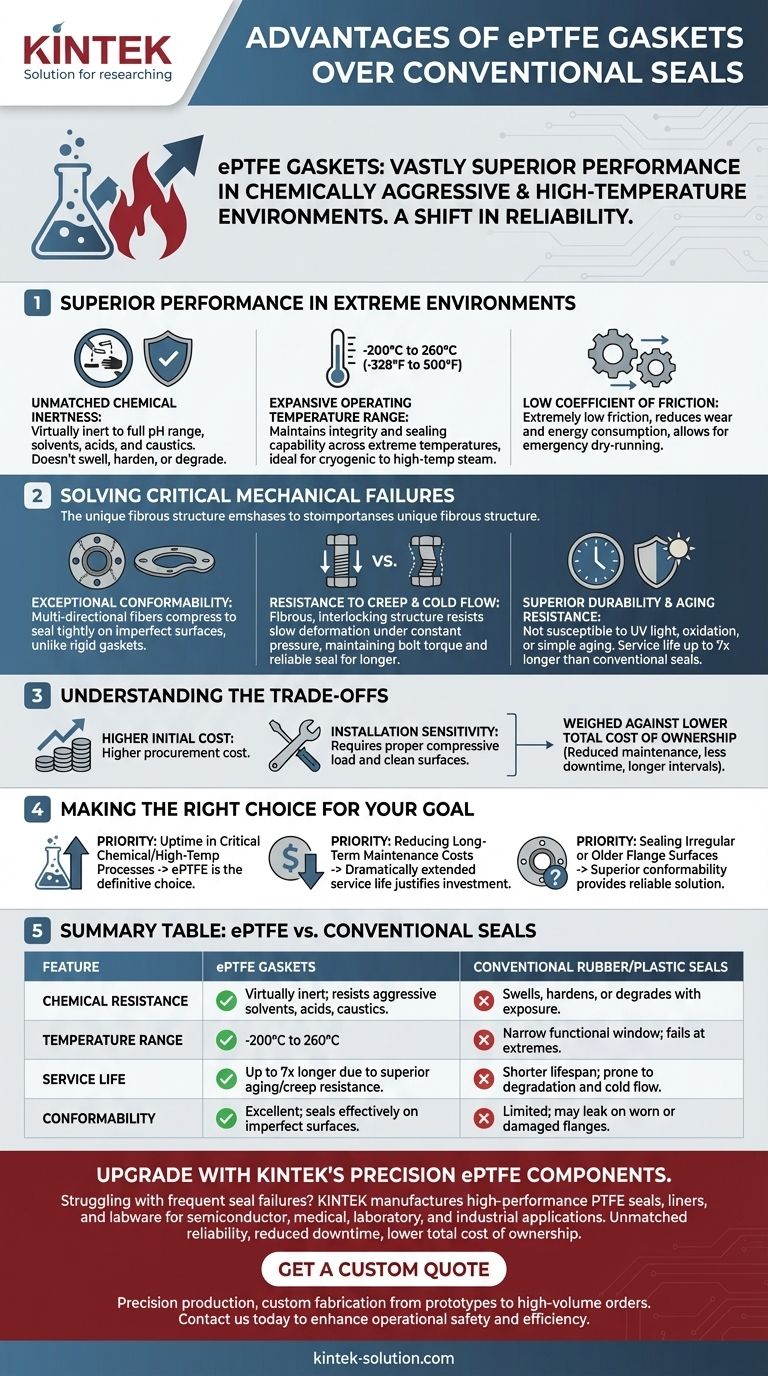

In short, ePTFE gaskets offer vastly superior performance in chemically aggressive and high-temperature environments compared to conventional rubber and plastic seals. Their unique fibrous structure provides exceptional chemical inertness, a wider operating temperature range, and a significantly longer service life, fundamentally solving common failure points like material degradation, creep, and cold flow.

The core advantage is not just a material upgrade; it's a shift in reliability. ePTFE excels where rubber and plastics fail, offering unmatched stability in extreme conditions that translates directly to reduced downtime, lower maintenance costs, and increased operational safety.

Superior Performance in Extreme Environments

The decision to use ePTFE is typically driven by operational conditions that exceed the capabilities of traditional elastomers. Its inherent properties make it uniquely suited for the most demanding industrial applications.

Unmatched Chemical Inertness

Unlike rubber or plastics, which can swell, harden, or degrade when exposed to specific chemicals, ePTFE is virtually inert. It withstands a full pH range and is unaffected by even the most aggressive solvents, acids, and caustics found in industrial processes.

Expansive Operating Temperature Range

Conventional rubber seals have a narrow functional temperature window. In contrast, ePTFE gaskets maintain their integrity and sealing capability across a vast range, typically from -200°C to 260°C (-328°F to 500°F). This makes them ideal for applications involving cryogenic liquids or high-temperature steam.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is especially critical in dynamic or rotary applications, as it reduces wear and energy consumption and allows for a degree of dry-running capability in emergencies where rubber would fail catastrophically.

Solving Critical Mechanical Failures

Beyond its environmental resistance, the expanded structure of ePTFE addresses mechanical failures that plague other sealing materials, including standard solid PTFE.

Exceptional Conformability

When compressed, the multi-directional fibers of ePTFE intertwine and compress. This allows the material to conform perfectly to flange surface imperfections, creating a tight, reliable seal even on worn or slightly damaged surfaces where a rigid or standard rubber gasket might leak.

Resistance to Creep and Cold Flow

A primary weakness of conventional plastics and even solid PTFE is creep, or cold flow, where the material slowly deforms under constant pressure over time, leading to a loss of seal. The fibrous, interlocking structure of ePTFE fundamentally resists this phenomenon, maintaining bolt torque and a reliable seal for far longer.

Superior Durability and Aging Resistance

ePTFE is not susceptible to degradation from UV light, oxidation, or simple aging. This leads to a service life that can be more than seven times longer than conventional rubber and plastic seals, which can become brittle or lose their elasticity over time.

Understanding the Trade-offs

While its advantages are significant, ePTFE is not a universal solution. An objective assessment requires acknowledging its specific characteristics.

Higher Initial Material Cost

ePTFE is a high-performance material, and its upfront procurement cost is typically higher than that of standard rubber or plastic gaskets. This initial expense must be weighed against the lower total cost of ownership due to reduced maintenance, less downtime, and longer replacement intervals.

Installation Sensitivity

To achieve a durable seal, ePTFE requires proper compressive load and clean, well-prepared flange surfaces. While it is excellent at conforming to minor imperfections, improper or uneven bolt torque can compromise the integrity of the seal, negating its advanced properties.

Making the Right Choice for Your Goal

Selecting the right sealing material depends entirely on the operational demands and long-term objectives of your system.

- If your primary focus is uptime in critical chemical or high-temperature processes: ePTFE is the definitive choice due to its unmatched chemical and thermal stability.

- If your primary focus is reducing long-term maintenance costs: The dramatically extended service life and reliability of ePTFE almost always justify its initial investment.

- If your primary focus is sealing irregular or older flange surfaces: The superior conformability of ePTFE provides a reliable solution where other materials would likely fail.

Ultimately, choosing ePTFE is an engineering decision to prioritize long-term reliability and safety in demanding applications.

Summary Table:

| Feature | ePTFE Gaskets | Conventional Rubber/Plastic Seals |

|---|---|---|

| Chemical Resistance | Virtually inert; resists aggressive solvents, acids, and caustics | Swells, hardens, or degrades with chemical exposure |

| Temperature Range | -200°C to 260°C (-328°F to 500°F) | Narrow functional window; fails at extremes |

| Service Life | Up to 7x longer due to superior aging and creep resistance | Shorter lifespan; prone to degradation and cold flow |

| Conformability | Excellent; seals effectively on imperfect surfaces | Limited; may leak on worn or damaged flanges |

Upgrade your sealing solutions with KINTEK's precision ePTFE components.

Struggling with frequent seal failures in aggressive chemical or high-temperature environments? KINTECH manufactures high-performance PTFE components—including seals, liners, and labware—specifically engineered for semiconductor, medical, laboratory, and industrial applications. Our ePTFE gaskets deliver unmatched reliability, reduce downtime, and lower your total cost of ownership.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. Contact us today to discuss how our ePTFE solutions can enhance your operational safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the advantages of ceramic fillers over glass reinforcements? Superior Thermal & High-Frequency Performance

- What makes PTFE washers suitable for the food industry? Ensure Safety, Hygiene & Durability

- What are the drawbacks of using PTFE for sealing needs? The Critical Trade-offs in Chemical vs. Mechanical Performance

- What are some common types of PTFE seals? Choose the Right Seal for Static or Dynamic Applications

- What types of chemical media are PTFE gaskets resistant to? Achieve Leak-Free Sealing in Aggressive Environments

- What industries commonly use PTFE-lined pipes? Achieve Ultimate Corrosion Resistance & Purity

- How does PTFE's thermal expansion and contraction affect its machining and application? Master Dimensional Stability

- How do custom Teflon rotary shaft seals contribute to operational efficiency? Maximize Reliability & Cut Costs