In high-performance circuit design, ceramic fillers offer decisive advantages over traditional woven glass reinforcements, particularly in thermal management and high-frequency signal integrity. They provide superior thermal conductivity, eliminate signal-distorting fiber weave effects, and allow for a more uniform and tunable dielectric environment.

While woven glass is a cost-effective standard, ceramic-filled laminates are a superior engineering solution for applications where thermal performance and high-frequency signal predictability are non-negotiable. They trade higher cost for a homogenous material structure that solves problems inherent in a woven fabric.

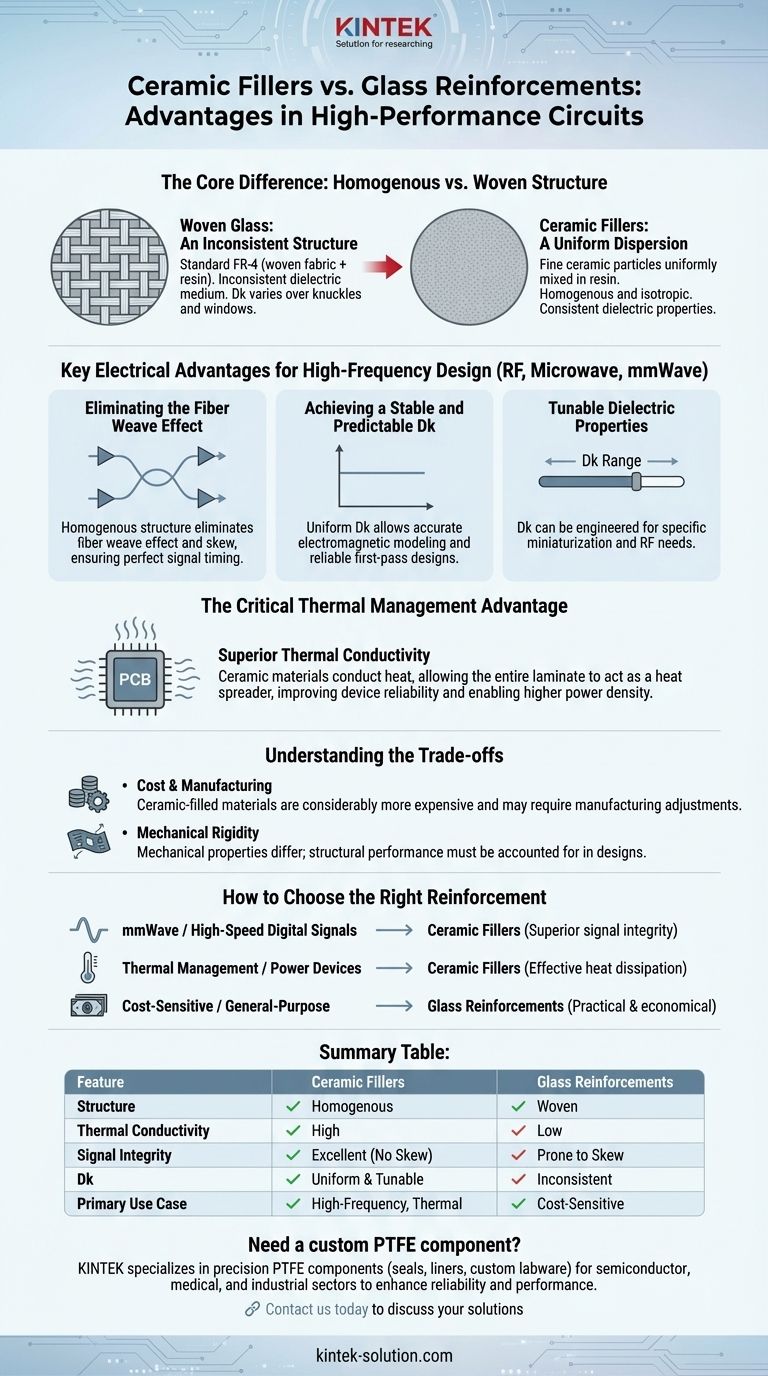

The Core Difference: Homogenous vs. Woven Structure

The fundamental advantages of ceramic fillers stem from their physical structure within the printed circuit board (PCB) laminate material.

Woven Glass: An Inconsistent Structure

Standard PCB materials like FR-4 use a woven fabric of glass fibers embedded in an epoxy resin.

This creates an inconsistent dielectric medium. A signal trace may pass over a fiber-dense "knuckle" or a resin-rich "window," each having a different dielectric constant (Dk).

Ceramic Fillers: A Uniform Dispersion

Ceramic-filled laminates consist of fine ceramic particles evenly mixed into a resin system.

This creates a homogenous and isotropic material. From the perspective of a signal trace, the dielectric properties are consistent at any point and in any direction.

Key Electrical Advantages for High-Frequency Design

For circuits operating at high frequencies (RF, microwave, mmWave) or high data rates, the uniformity of ceramic fillers provides critical performance benefits.

Eliminating the Fiber Weave Effect

The inconsistent Dk of a woven glass fabric is the primary cause of the fiber weave effect.

When a high-speed differential pair travels across this inconsistent weave, one signal line can speed up or slow down relative to the other. This timing difference is known as skew, and it severely degrades signal integrity.

Because ceramic-filled materials are homogenous, they completely eliminate the fiber weave effect, ensuring differential signals remain perfectly timed.

Achieving a Stable and Predictable Dielectric Constant (Dk)

The uniform Dk of ceramic-filled materials makes circuit performance highly predictable.

Engineers can model electromagnetic behavior with greater accuracy, leading to more reliable designs that work as expected on the first iteration without unexpected signal integrity issues.

Tunable Dielectric Properties

The type and concentration of ceramic filler can be engineered to achieve specific dielectric properties.

This allows for laminates with a much wider range of Dk values than is possible with glass/resin systems, which can be useful for miniaturizing circuit elements in certain lower-frequency RF designs.

The Critical Thermal Management Advantage

Beyond electrical performance, ceramic fillers offer a significant thermal benefit that glass reinforcements cannot match.

Superior Thermal Conductivity

Ceramic materials are inherently better at conducting heat than glass, which is a thermal insulator.

By dispersing ceramic particles throughout the resin, the entire laminate becomes more thermally conductive. This allows the PCB itself to act as a heat spreader, pulling damaging heat away from active components like power amplifiers or processors.

This enhanced thermal management improves device reliability and allows for higher power density in the design.

Understanding the Trade-offs

Choosing a ceramic-filled laminate involves considering its specific downsides compared to the industry standard.

Cost and Manufacturing

The most significant trade-off is cost. Ceramic-filled high-performance materials are considerably more expensive than standard FR-4 with woven glass.

Their unique properties can also require adjustments to the PCB manufacturing process.

Mechanical Rigidity

Woven glass provides exceptional mechanical strength and rigidity to a PCB. While ceramic-filled laminates are robust, their mechanical properties differ and must be accounted for in designs requiring specific structural performance.

How to Choose the Right Reinforcement

Your choice depends directly on the primary performance driver of your design.

- If your primary focus is mmWave or high-speed digital signals: Ceramic fillers are the superior choice to eliminate fiber weave skew and ensure signal integrity.

- If your primary focus is thermal management for power devices: Ceramic-filled materials provide the thermal conductivity needed to manage heat effectively and improve reliability.

- If your primary focus is cost-sensitive, general-purpose circuitry: Traditional woven glass reinforcements remain the most practical and economical option.

By understanding these fundamental differences, you can select the material that provides the precise engineering performance your application demands.

Summary Table:

| Feature | Ceramic Fillers | Glass Reinforcements |

|---|---|---|

| Structure | Homogenous, isotropic | Woven, inconsistent |

| Thermal Conductivity | High (acts as heat spreader) | Low (thermal insulator) |

| Signal Integrity | Eliminates fiber weave effect & skew | Prone to fiber weave effect & skew |

| Dielectric Constant (Dk) | Uniform and tunable | Inconsistent |

| Primary Use Case | High-frequency, high-power, thermal management | Cost-sensitive, general-purpose circuits |

Need a custom PTFE component for your high-performance PCB application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures your designs achieve optimal thermal management and signal integrity.

Contact us today to discuss how our PTFE solutions can enhance your product's reliability and performance.

Visual Guide

Related Products

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What industries commonly use PTFE and why? Unlock the Power of PTFE for Extreme Environments

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What are the key advantages of PTFE compared to other engineering plastics? Unmatched Chemical & Thermal Resistance

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments