For precision-grade PTFE balls, tolerances are typically defined by size. Smaller diameter balls often have a diameter tolerance of +/- 0.003 inches, while larger diameter balls have a looser tolerance of +/- 0.005 inches. However, a much wider "standard" tolerance of ±5% also exists for less critical, commercial-grade applications.

The key to understanding PTFE ball tolerances is recognizing that they depend on two factors: the ball's size and its manufacturing grade. You must distinguish between "precision grade" balls with tight, absolute tolerances and "standard grade" balls with much looser, percentage-based tolerances.

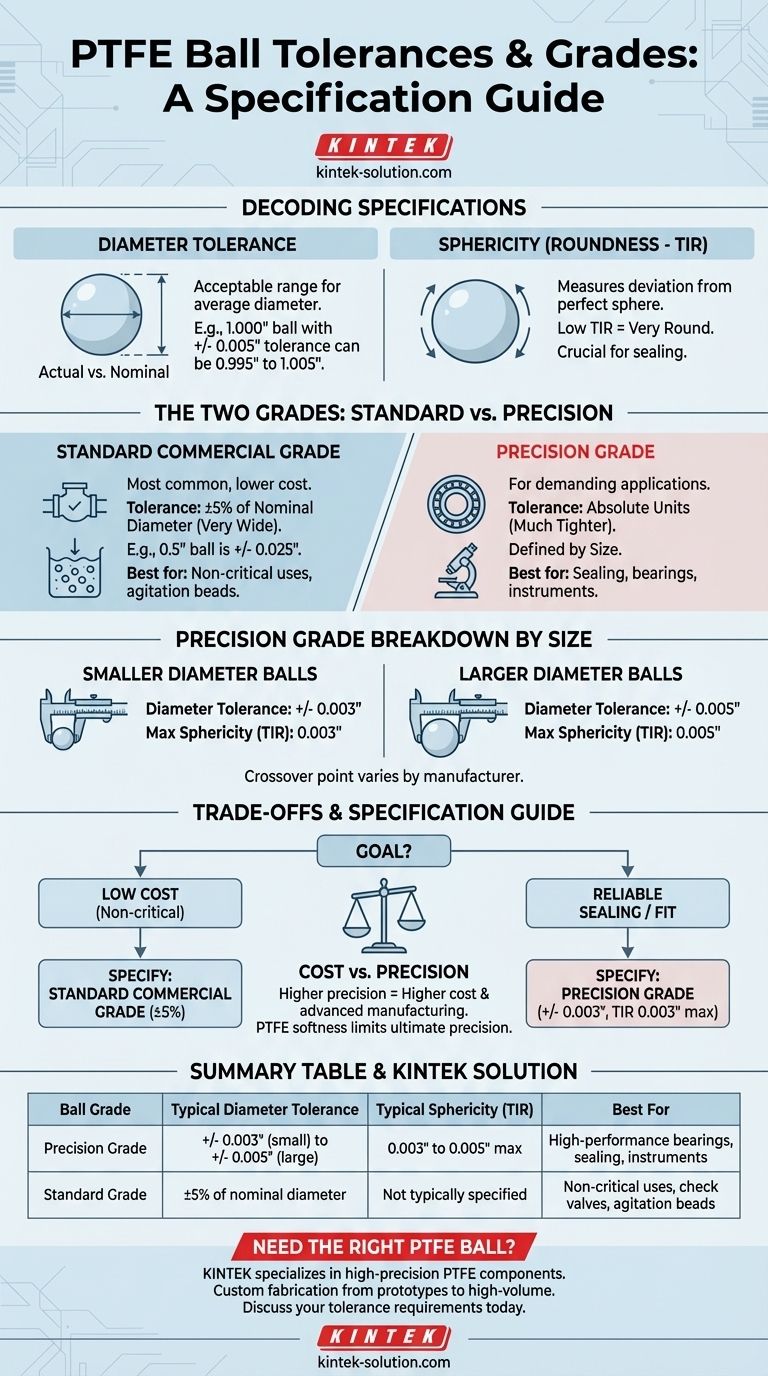

Decoding PTFE Ball Specifications

To specify the correct component, you must understand the distinct measurements that define its quality and precision. These are not interchangeable terms.

Diameter Tolerance

This is the most common specification. It defines the acceptable range for the average diameter of the ball.

A tolerance of +/- 0.005 inches on a 1.000-inch ball means the actual diameter can be anywhere between 0.995 and 1.005 inches.

Sphericity (Roundness)

This measures how close the ball is to a perfect sphere. It is often expressed as Total Indicator Reading (TIR).

A low TIR value indicates a very round ball. A ball can be within its diameter tolerance but still be out-of-round (egg-shaped), which can compromise sealing performance.

The Two Grades of PTFE Balls

The vast difference in reported tolerances stems from two distinct manufacturing grades. Failing to specify the grade is a common source of error.

Standard Commercial Grade

This is the most common and least expensive option. It is suitable for applications where high precision is not the primary concern, such as in simple check valves or as fluid agitation beads.

The tolerance for this grade is often expressed as a percentage, typically ±5% of the nominal diameter. For a 0.5-inch ball, this translates to a very wide tolerance of +/- 0.025 inches.

Precision Grade

This grade is intended for more demanding applications like high-performance bearings, specialized valves, or scientific instruments where a predictable fit and seal are critical.

Tolerances for precision balls are specified in absolute units (inches or millimeters) and are much tighter. They are typically broken down by size.

- Smaller Diameter Balls: Generally have a diameter tolerance of +/- 0.003" and a maximum sphericity (TIR) of 0.003".

- Larger Diameter Balls: Typically have a diameter tolerance of +/- 0.005" and a maximum sphericity (TIR) of 0.005".

The exact crossover point between "small" and "large" can vary by manufacturer but reflects the increasing difficulty of controlling dimensions on larger parts.

Understanding the Trade-offs

Choosing the right tolerance involves balancing performance requirements with practical constraints.

Cost vs. Precision

There is a direct and significant cost increase associated with tighter tolerances. Precision-grade balls require more advanced manufacturing, sorting, and inspection processes, making them substantially more expensive than standard-grade balls.

The Limits of the Material

PTFE is a relatively soft and thermally sensitive polymer. While its chemical resistance is outstanding, its dimensional stability is lower than that of metals or ceramics. This inherent softness limits the absolute level of precision that can be economically achieved.

The Importance of Clear Specification

Never assume a supplier will provide a precision-grade part if it is not explicitly requested. If your application requires tight tolerances, you must state both the required diameter tolerance and the maximum TIR on your engineering drawings and purchase orders.

How to Specify the Correct Ball for Your Project

Use your application's primary goal to guide your specification.

- If your primary focus is low cost for non-critical applications: Specify a "standard commercial grade" ball and design your system to accommodate the wider ±5% tolerance.

- If your primary focus is reliable sealing or consistent fit: Specify a "precision grade" ball and clearly state the required diameter tolerance (e.g., +/- 0.003") and TIR (e.g., 0.003" max).

- If your primary focus is extreme precision beyond standard offerings: You must consult directly with a specialty manufacturer about custom grinding processes or consider an alternative high-performance material like PEEK or a ceramic.

Ultimately, a clear specification is the foundation for a successful design.

Summary Table:

| Ball Grade | Typical Diameter Tolerance | Typical Sphericity (TIR) | Best For |

|---|---|---|---|

| Precision Grade | +/- 0.003" (small) to +/- 0.005" (large) | 0.003" to 0.005" max | High-performance bearings, sealing, instruments |

| Standard Grade | ±5% of nominal diameter | Not typically specified | Non-critical uses, check valves, agitation beads |

Need the Right PTFE Ball for Your Project?

KINTEK specializes in manufacturing high-precision PTFE components, including balls, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, where precision is critical.

Whether you require standard-grade components for cost-efficiency or precision-grade parts for demanding applications, we provide custom fabrication from prototypes to high-volume orders.

Let us help you specify the perfect component. Contact our experts today to discuss your tolerance requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance