The primary advantages of Teflon bearings are their extremely low friction, outstanding chemical inertness, and ability to perform across a vast temperature range. This unique combination of properties makes them self-lubricating, which dramatically reduces maintenance requirements and extends service life. They excel in applications where traditional lubricated metal bearings would quickly fail due to corrosion, extreme heat, or cryogenic cold.

The core value of Teflon bearings is not just their material properties, but their ability to solve critical engineering challenges. They provide unparalleled reliability in extreme environments where conventional lubrication is impossible or undesirable.

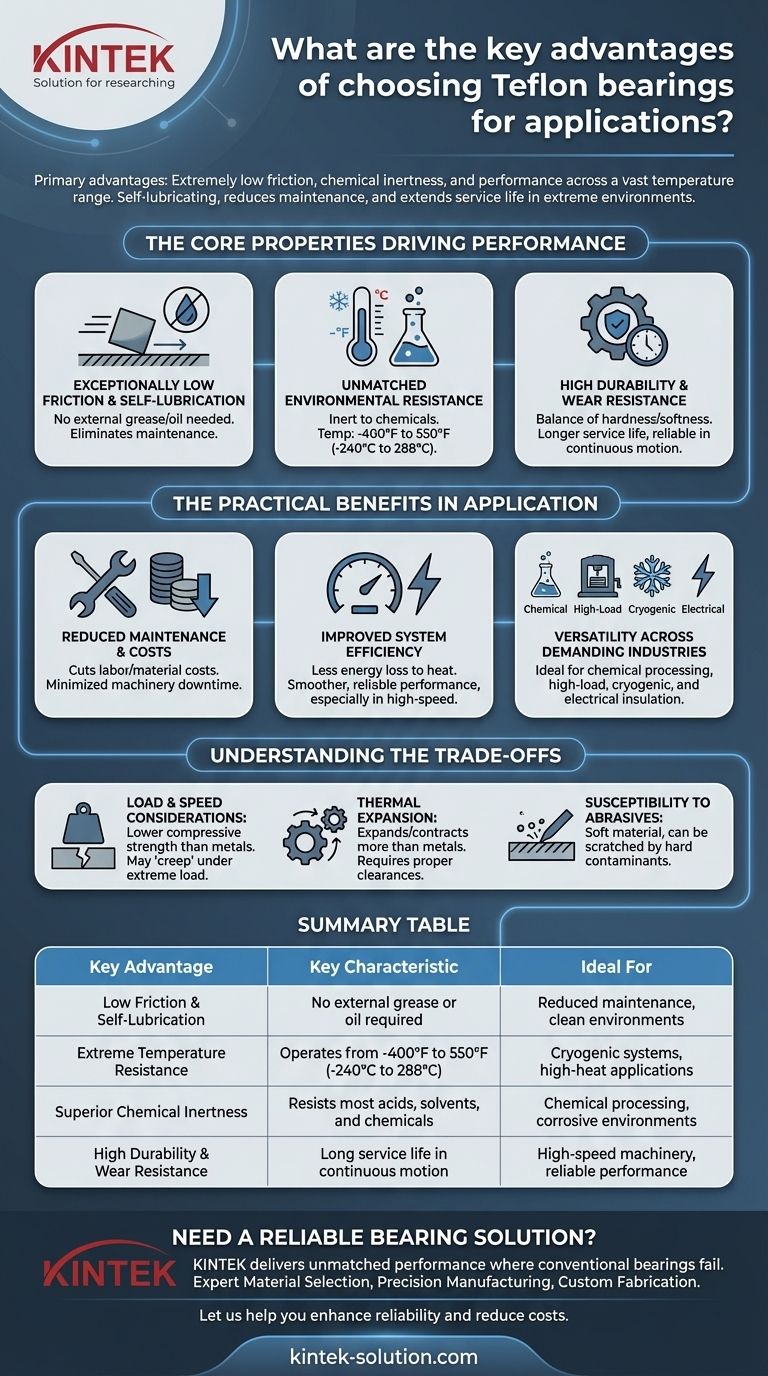

The Core Properties Driving Performance

To understand the advantages of Teflon bearings, we must first examine the inherent characteristics of the material itself. These properties work in concert to deliver superior performance in specialized applications.

Exceptionally Low Friction and Self-Lubrication

Teflon (PTFE) possesses one of the lowest coefficients of friction of any solid material known. This creates a naturally non-stick, self-lubricating surface.

This means the bearing requires no external grease or oil to operate smoothly. This characteristic is fundamental to its value, as it eliminates the need for lubrication systems and frequent maintenance.

Unmatched Environmental Resistance

Teflon is renowned for its stability in harsh conditions. It is virtually inert to most industrial chemicals, acids, and solvents, making it ideal for corrosive environments.

Furthermore, it maintains its integrity across an exceptionally wide temperature spectrum. It is effective in high-temperature applications up to 550°F (288°C) and cryogenic uses down to -400°F (-240°C).

High Durability and Wear Resistance

The material composition provides a unique balance of hardness and softness. This allows Teflon bearings to resist wear over long periods, especially in continuous motion applications.

This durability translates directly to a longer service life for the component, contributing to the overall reliability of the machinery it is part of.

The Practical Benefits in Application

These core properties translate into tangible operational and financial benefits when Teflon bearings are specified for the right job.

Reduced Maintenance and Operational Costs

The self-lubricating nature of Teflon is its most significant cost-saving feature. It drastically reduces the labor and material costs associated with regular lubrication schedules.

This also minimizes machinery downtime, as components do not need to be stopped for maintenance as frequently. For hard-to-access components, this is a critical advantage.

Improved System Efficiency

Because there is very little friction to overcome, systems using Teflon bearings operate more efficiently. Less energy is wasted as heat, leading to smoother and more reliable mechanical performance.

This efficiency is particularly valuable in high-speed applications or delicate machinery where minimal resistance is crucial.

Versatility Across Demanding Industries

The combination of chemical, thermal, and electrical resistance makes Teflon a uniquely versatile solution.

It is invaluable in chemical processing, high-load/high-speed machinery, cryogenic systems, and as electrical insulation due to its high dielectric strength.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. An objective assessment requires understanding its limitations compared to traditional metallic bearings.

Load and Speed Considerations

Teflon is a polymer, not a metal. While it performs well in "high-load" contexts for a plastic, it has a lower compressive strength than steel or bronze.

In applications with extreme point loading or impact forces, a metallic bearing may be a more suitable choice. The material can be prone to "creep," or slow deformation under a sustained heavy load.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than metals. This means it expands and contracts more significantly with temperature changes.

Design engineers must account for this property by ensuring proper clearances and tolerances to prevent binding or failure in systems with wide temperature fluctuations.

Susceptibility to Abrasives

While chemically durable, Teflon is a relatively soft material. In environments contaminated with hard, abrasive particles like sand or metal filings, the bearing surface can be scratched or worn down prematurely.

Making the Right Choice for Your Application

Selecting the correct bearing material depends entirely on the primary demands of your specific application.

- If your primary focus is extreme temperatures or corrosive chemicals: Teflon is often the default choice due to its unparalleled chemical inertness and wide operating temperature range.

- If your primary focus is eliminating lubrication and reducing maintenance: Its self-lubricating properties make it ideal for clean environments, food processing, or hard-to-reach locations where regular maintenance is impractical.

- If your primary focus is extreme mechanical load capacity: You must carefully evaluate the specific forces involved, as a traditional metallic bearing may offer superior strength and rigidity for the most demanding structural roles.

Ultimately, choosing Teflon bearings is a strategic decision to engineer for reliability and longevity in environments where conventional components would fail.

Summary Table:

| Key Advantage | Key Characteristic | Ideal For |

|---|---|---|

| Low Friction & Self-Lubrication | No external grease or oil required | Reduced maintenance, clean environments |

| Extreme Temperature Resistance | Operates from -400°F to 550°F (-240°C to 288°C) | Cryogenic systems, high-heat applications |

| Superior Chemical Inertness | Resists most acids, solvents, and chemicals | Chemical processing, corrosive environments |

| High Durability & Wear Resistance | Long service life in continuous motion | High-speed machinery, reliable performance |

Need a Reliable Bearing Solution for Extreme Conditions?

Teflon (PTFE) bearings from KINTEK are engineered to deliver unmatched performance where conventional bearings fail. We specialize in manufacturing high-precision PTFE components, including custom bearings, seals, and liners, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Material Selection: Ensure the right PTFE formulation for your specific temperature, chemical, and load requirements.

- Precision Manufacturing: Achieve the exact tolerances and performance characteristics your application demands.

- Custom Fabrication: From initial prototypes to high-volume production runs, we build to your specifications.

Let us help you enhance system reliability, reduce maintenance costs, and solve your toughest engineering challenges.

Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability