In industrial applications, Polytetrafluoroethylene (PTFE) bellows are the material of choice in any sector that handles aggressive or high-purity fluids. Their near-universal chemical inertness makes them essential in industries such as chemical and petrochemical processing, pharmaceutical and semiconductor manufacturing, and wastewater treatment, where material failure is not an option.

The decision to use PTFE bellows is driven by a need for ultimate reliability in corrosive or sterile environments. While other materials may offer greater mechanical strength, none can match PTFE's ability to ensure process purity and operational safety when handling the most challenging chemicals.

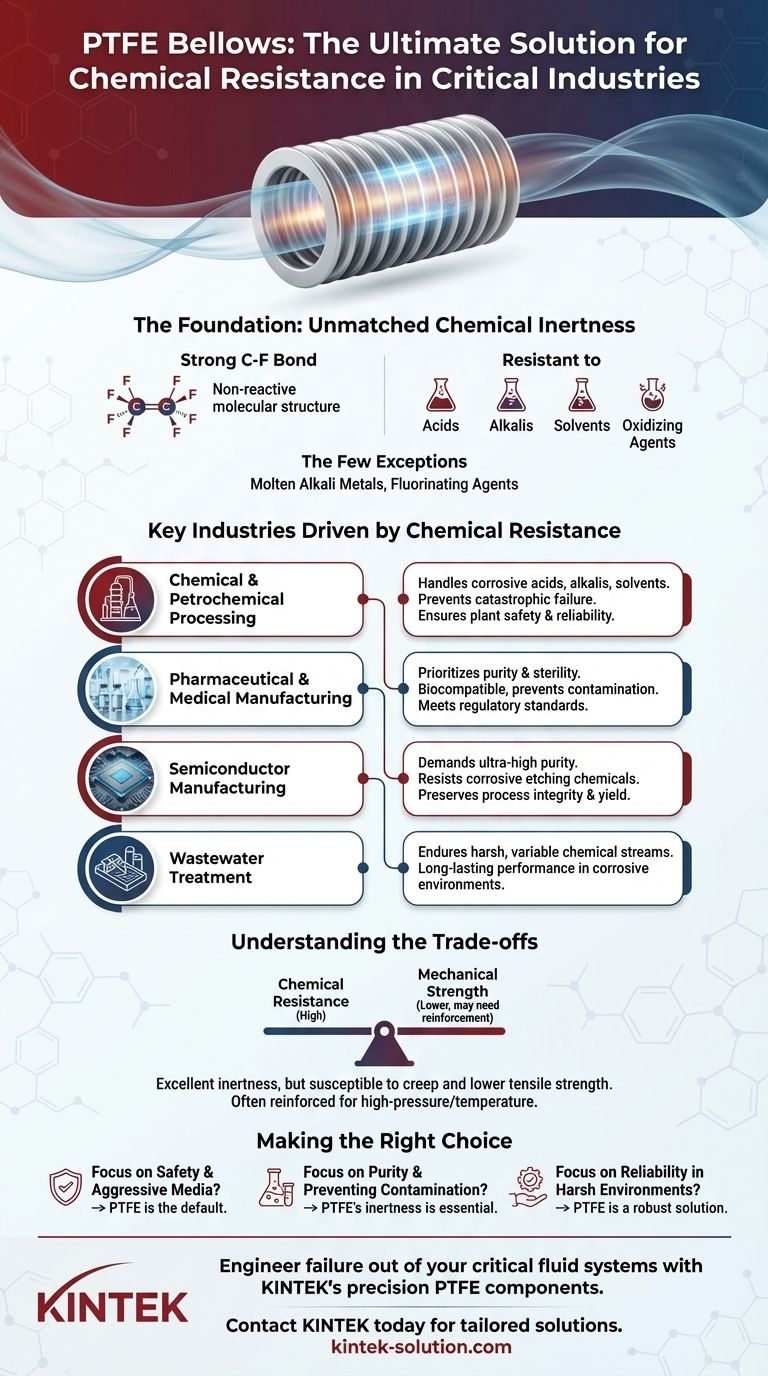

The Foundation: Unmatched Chemical Inertness

What Makes PTFE So Resistant?

PTFE is a fluoropolymer with an exceptionally strong carbon-fluorine bond, one of the strongest in organic chemistry. This molecular structure makes it stable and non-reactive with almost any substance.

It is resistant to a vast range of chemicals, including concentrated acids, alkalis, solvents, and powerful oxidizing agents. This comprehensive resistance simplifies material selection for complex chemical processes.

The Few Exceptions

Only a handful of highly reactive substances can attack PTFE. These are typically limited to molten alkali metals (like sodium) and highly reactive fluorinating agents (like fluorine gas) under specific conditions. For virtually all other industrial applications, PTFE is considered completely inert.

Key Industries Driven by Chemical Resistance

The use of PTFE bellows is not arbitrary; it is a direct response to specific operational challenges within each industry.

Chemical and Petrochemical Processing

In these plants, bellows are constantly exposed to a wide array of corrosive chemicals, often at elevated temperatures. PTFE bellows prevent catastrophic failures that could be caused by material degradation.

They are critical for maintaining plant safety and process reliability, absorbing movement in piping systems that transport aggressive media like acids, bases, and organic solvents.

Pharmaceutical and Medical Manufacturing

This sector prioritizes purity and sterility above all else. PTFE is not only chemically inert but also biocompatible, meaning it does not react with biological fluids or leach harmful substances.

PTFE bellows are used to create flexible, sterile connections in processing lines, preventing contamination and ensuring the final product meets stringent regulatory standards.

Semiconductor Manufacturing

The production of microchips demands an ultra-high purity environment. Even microscopic contamination can ruin entire batches of wafers.

PTFE bellows are used in equipment handling the highly corrosive chemicals required for etching and cleaning. Their inertness ensures no ions or particles are leached into the process fluids, preserving process integrity.

Wastewater Treatment and Pollution Control

Municipal and industrial wastewater streams contain a harsh, unpredictable mix of chemicals, acids, and abrasive solids.

PTFE bellows provide a durable solution for these corrosive and variable environments, outlasting many metals and other plastics that would quickly degrade.

Understanding the Trade-offs

While PTFE's chemical resistance is its defining feature, a complete technical evaluation requires looking at its entire performance profile.

Balancing Inertness with Mechanical Demands

PTFE is not as rigid or strong as metal. It is more susceptible to creep (deformation under sustained load) and has a lower tensile strength compared to stainless steel or high-nickel alloys.

In high-pressure or high-temperature applications, the design must account for these mechanical limitations. Often, PTFE bellows are reinforced with external metal rings or used as liners within a more robust metallic expansion joint to combine the strengths of both materials.

A Premium Material for a Critical Function

PTFE is generally a more expensive material than common elastomers or standard metals. Its use is an investment in long-term reliability and risk mitigation.

The higher initial cost is often justified by reduced downtime, enhanced safety, and the prevention of costly failures in critical systems.

Making the Right Choice for Your Goal

The decision to specify PTFE bellows should be based on your primary operational driver.

- If your primary focus is safety and handling aggressive media: PTFE is the default choice for systems transporting corrosive acids, solvents, or mixed chemical streams.

- If your primary focus is process purity and preventing contamination: PTFE's inertness and biocompatibility are essential for pharmaceutical, semiconductor, and food-grade applications.

- If your primary focus is reliability in harsh, variable environments: The broad-spectrum resistance of PTFE makes it a robust solution for demanding applications like wastewater treatment or pollution control.

Ultimately, choosing PTFE is a strategic decision to engineer failure out of your most critical fluid handling systems.

Summary Table:

| Industry | Primary Use Case | Key Benefit of PTFE Bellows |

|---|---|---|

| Chemical & Petrochemical | Transporting aggressive acids, solvents, and alkalis | Ultimate reliability and plant safety |

| Pharmaceutical & Medical | Sterile connections in processing lines | Biocompatibility and prevention of contamination |

| Semiconductor | Handling ultra-pure, corrosive etching chemicals | Preservation of process integrity and yield |

| Wastewater Treatment | Enduring harsh, variable chemical streams | Long-lasting performance in corrosive environments |

Engineer failure out of your critical fluid systems with KINTEK's precision PTFE components.

If your operations in the semiconductor, medical, laboratory, or industrial sectors demand the ultimate in chemical resistance and purity, our custom-fabricated PTFE seals, liners, bellows, and labware are the solution. We combine precision production with expertise in both prototypes and high-volume orders to ensure your systems achieve maximum reliability and safety.

Contact KINTEK today to discuss your specific requirements and let us provide a solution tailored to your most challenging environment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the weaknesses of glass fiber filled PTFE? A Guide to Material Trade-offs

- What are the primary applications of PTFE PCBs? The Ultimate Guide for High-Frequency & Harsh Environments

- What types of chemical solutions are PTFE control valves suitable for? Handle Corrosive Acids, Bases & More

- What are the machining advantages of PTFE rod? Achieve Cost-Effective, Complex Parts

- What are PTFE seals and what makes them exceptional? Unmatched Performance in Extreme Conditions

- What are the features of Polytetrafluoroethylene (PTFE) with Mineral Fill? Achieve Superior Durability in Demanding Applications

- What is a PTFE lined butterfly valve and how does it work? Control Corrosive & Pure Fluids Safely

- Why is PTFE packing considered a reliable and cost-effective option? Maximize Uptime & Lower Costs