While a powerful composite, glass fiber filled PTFE is not a universally superior material. Its primary weaknesses are a higher coefficient of friction, an abrasive nature that can damage softer mating surfaces, reduced resistance to gas permeation, and a specific chemical vulnerability to hydrogen fluoride and strong alkalines.

Adding glass fiber to PTFE is a classic engineering trade-off. You gain significant mechanical strength and resistance to wear, but you sacrifice the ultra-low friction, chemical inertness, and non-abrasive qualities that define pure PTFE.

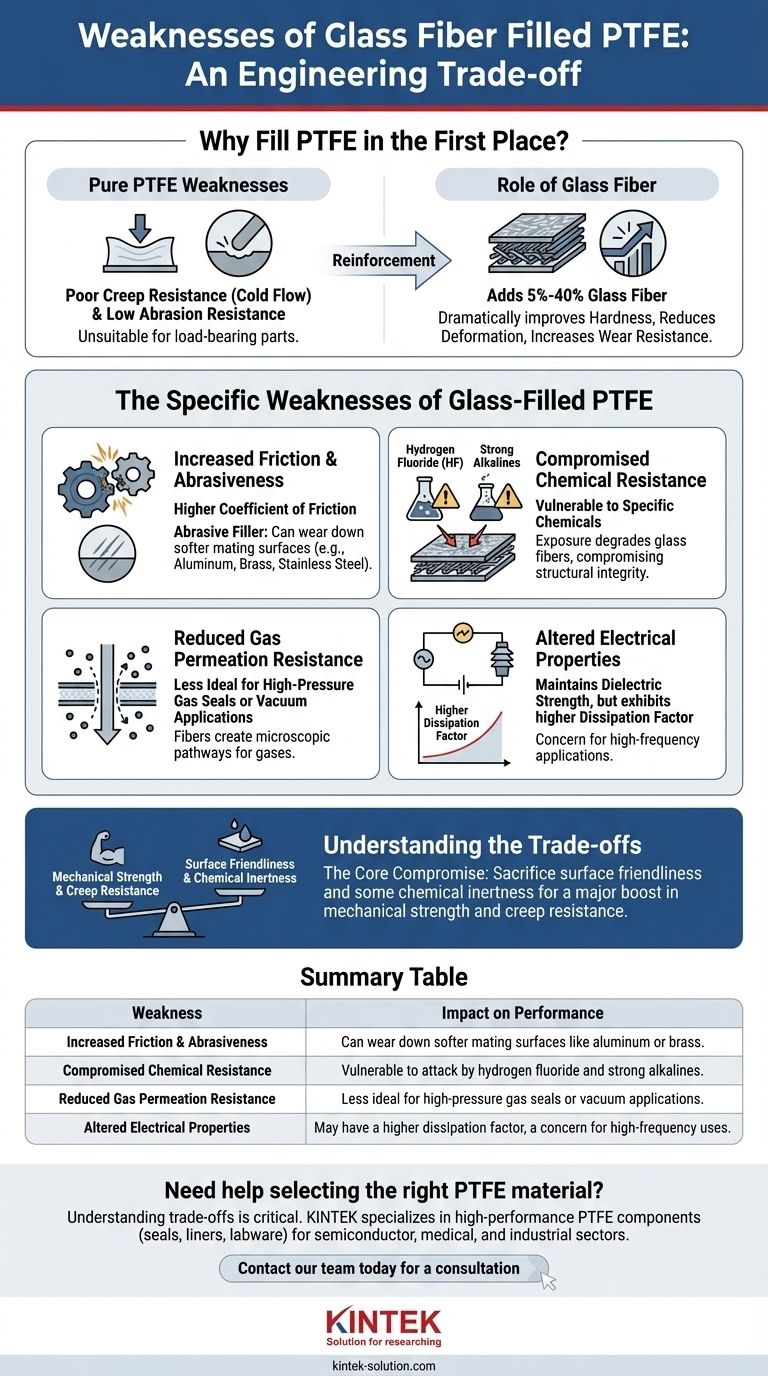

Why Fill PTFE in the First Place?

The Weakness of Pure PTFE

Pure, or "virgin," Polytetrafluoroethylene (PTFE) is famously soft and has a very low coefficient of friction. However, it suffers from significant drawbacks in mechanical applications.

Its primary weaknesses are poor creep resistance (a tendency to deform permanently under load, also known as "cold flow") and low abrasion resistance. This makes it unsuitable for many load-bearing parts like bearings or seals under pressure.

The Role of Glass Fiber

To overcome these limitations, fillers are added. Glass fiber, typically in concentrations from 5% to 40%, is introduced to the PTFE matrix to create a composite material.

This reinforcement dramatically improves hardness, reduces deformation under load, and increases wear resistance, making the material far more durable for demanding mechanical roles.

The Specific Weaknesses of Glass-Filled PTFE

Strengthening PTFE with glass fibers introduces a new set of compromises that are critical to understand for proper material selection.

Increased Friction and Abrasiveness

While pure PTFE is known for its slickness, adding glass fibers increases the material's coefficient of friction.

More importantly, the glass fibers act as an abrasive filler. When used against softer metals like aluminum, brass, or certain stainless steels, glass-filled PTFE can wear down the mating surface, shortening the life of the entire assembly.

Compromised Chemical Resistance

Pure PTFE is renowned for its exceptional chemical inertness. However, the glass filler is not as resilient.

Glass-filled PTFE is susceptible to attack by hydrogen fluoride and strong alkaline solutions. Exposure to these chemicals can degrade the glass fibers, compromising the material's structural integrity.

Reduced Gas Sealing (Permeability)

The introduction of fibers into the smooth PTFE matrix can create microscopic pathways for gases to travel through the material.

This results in reduced resistance to gas permeation compared to virgin PTFE, making it a less ideal choice for high-pressure gas seals or vacuum applications where impermeability is critical.

Altered Electrical Properties

While glass is an excellent insulator, its presence slightly alters the electrical performance of the PTFE.

Glass-filled PTFE maintains good dielectric strength, making it a reliable electrical insulator. However, it may exhibit a higher dissipation factor, which can be a concern in some high-frequency applications where minimizing electrical loss is paramount.

Understanding the Trade-offs

Choosing a filled PTFE is about balancing competing properties. The weaknesses of one formulation are often the strengths of another.

Glass vs. Other Fillers

Fillers like carbon or graphite can also be added to PTFE. Unlike glass, carbon is electrically conductive, which completely changes its suitability for electrical applications. Carbon and graphite can offer improved wear resistance and lower friction than glass, but with their own set of chemical and mechanical trade-offs.

The Core Compromise

The decision to use glass-filled PTFE boils down to a single question: Are you willing to sacrifice surface friendliness and some chemical inertness for a major boost in mechanical strength and creep resistance?

Making the Right Choice for Your Application

Your specific goal will determine if glass-filled PTFE is the correct material.

- If your primary focus is mechanical strength and wear resistance: Glass-filled PTFE is an excellent choice, provided the mating surface is a hardened material that can resist abrasion.

- If your primary focus is ultra-low friction against a soft surface: Virgin PTFE or a graphite-filled compound is a more suitable option to prevent damage.

- If your primary focus is sealing gases or use in a vacuum: Virgin PTFE is superior due to its lower permeability.

- If your primary focus is chemical inertness in harsh environments: You must verify that the application will not expose the material to hydrogen fluoride or strong alkalines.

Understanding these inherent weaknesses allows you to leverage the strengths of glass-filled PTFE without risking application failure.

Summary Table:

| Weakness | Impact on Performance |

|---|---|

| Increased Friction & Abrasiveness | Can wear down softer mating surfaces like aluminum or brass. |

| Compromised Chemical Resistance | Vulnerable to attack by hydrogen fluoride and strong alkalines. |

| Reduced Gas Permeation Resistance | Less ideal for high-pressure gas seals or vacuum applications. |

| Altered Electrical Properties | May have a higher dissipation factor, a concern for high-frequency uses. |

Need help selecting the right PTFE material for your application?

Understanding the trade-offs between virgin PTFE and filled compounds like glass fiber is critical for your project's success. KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and custom labware.

We serve the semiconductor, medical, laboratory, and industrial sectors with precision production and custom fabrication from prototypes to high-volume orders. Let our expertise guide you to the optimal material solution that balances performance, durability, and cost.

Contact our team today for a consultation and see how KINTEK can add value to your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments