One of the most significant advantages of PTFE rod is its exceptional ease of machining. Its unique combination of softness, natural lubricity, and low friction allows it to be cut and shaped with minimal tool wear and force. This translates directly into more cost-effective and efficient production, especially for custom parts with complex designs.

PTFE’s machinability is a direct result of its core material properties. While its softness and low friction make it easy to cut, these same characteristics demand a specific approach—namely, managing heat, using sharp tools, and applying minimal clamping pressure—to achieve precision.

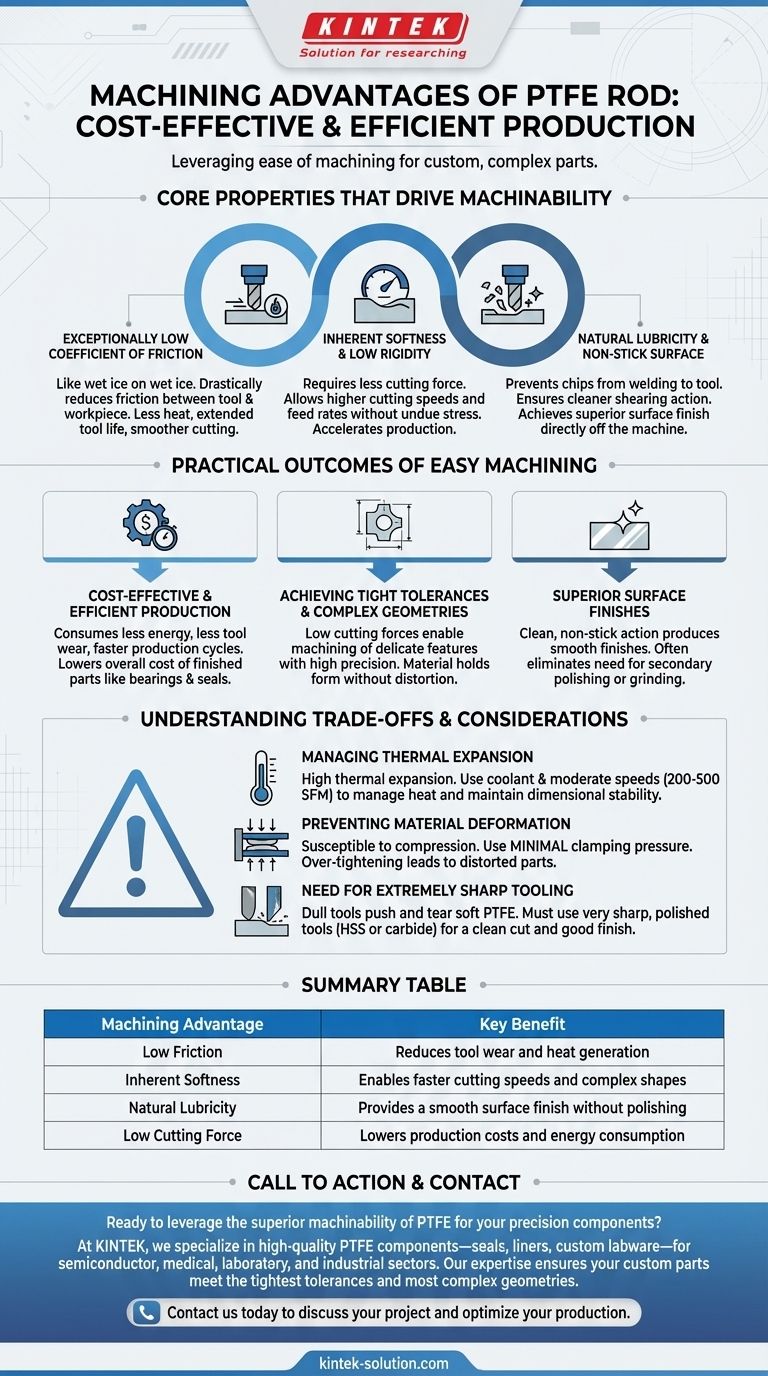

The Core Properties That Drive Machinability

The reason PTFE machines so well is not due to a single factor, but rather the interplay of several of its inherent characteristics. Understanding these properties is key to leveraging its full potential.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

During machining, this property drastically reduces the friction between the cutting tool and the workpiece. This means less heat is generated, tool life is extended, and the cutting action is smoother.

Inherent Softness and Low Rigidity

PTFE is a relatively soft polymer, which means it requires significantly less force to cut than metals or even other, harder plastics.

This softness allows for higher cutting speeds and feed rates without placing undue stress on the machine or the tooling, accelerating production cycles.

Natural Lubricity and Non-Stick Surface

The material's famous non-stick properties prevent chips from welding to the cutting tool, a common problem known as a "built-up edge."

This ensures a cleaner shearing action, which is critical for achieving a smooth, high-quality surface finish directly off the machine without secondary polishing.

The Practical Outcomes of Easy Machining

These underlying properties translate into tangible benefits during the manufacturing process, making PTFE a preferred choice for many applications.

Cost-Effective and Efficient Production

Because PTFE is easy to cut, it consumes less energy, causes less tool wear, and allows for faster production times. These factors combine to lower the overall cost of producing finished parts like custom bearings, seals, and insulators.

Achieving Tight Tolerances and Complex Geometries

The low cutting forces required for PTFE make it possible to machine delicate features and complex shapes with high precision. The material holds its form without the high stresses that can distort harder materials during aggressive cutting.

Superior Surface Finishes

The clean, non-stick cutting action naturally produces a very smooth surface. For many applications, the finish achieved during the primary machining operation is sufficient, eliminating the need for additional steps like grinding or micro-polishing.

Understanding the Trade-offs and Considerations

While PTFE is easy to machine, its unique properties also create challenges that must be managed to ensure accuracy and quality. Ignoring these can quickly ruin a part.

Managing Thermal Expansion

PTFE has a high rate of thermal expansion. Heat generated from cutting can cause the material to expand, leading to inaccurate dimensions once it cools.

Using a coolant system and moderate cutting speeds (such as 200-500 surface feet per minute) is crucial for managing temperature and maintaining dimensional stability.

Preventing Material Deformation

The softness that makes PTFE easy to cut also makes it susceptible to compression and distortion.

Minimal clamping pressure must be used when holding the rod in a chuck or vise. Over-tightening will deform the material, leading to parts that are out of round or dimensionally incorrect.

The Need for Extremely Sharp Tooling

A dull cutting tool will not shear the material cleanly. Instead, it will push, tear, or smear the soft PTFE, resulting in a poor surface finish and inaccurate dimensions.

Using very sharp, polished tools made from high-speed steel (HSS) or carbide is essential for a clean cut.

Controlling Vibration and Chips

Because it is soft, PTFE can be prone to vibration if excessive tool pressure is applied. This can harm the surface finish.

Proper feed rates (often between 0.002 and 0.010 inches per revolution) help ensure the tool is consistently engaged in the material, producing a smooth cut and preventing chatter.

How to Apply This to Your Project

Your machining strategy for PTFE should be dictated by the most critical outcome for your specific part.

- If your primary focus is dimensional accuracy: Prioritize thermal management by using coolant and avoiding overly aggressive cutting speeds that build up heat.

- If your primary focus is surface finish: Use extremely sharp, polished tools with a high rake angle to ensure a clean shearing action rather than tearing.

- If your primary focus is production efficiency: Leverage PTFE's softness for high feed rates, but carefully balance this against heat generation to maintain part quality and accuracy.

By understanding and respecting its unique properties, you can transform PTFE's machinability from a simple advantage into a powerful manufacturing asset.

Summary Table:

| Machining Advantage | Key Benefit |

|---|---|

| Low Friction | Reduces tool wear and heat generation |

| Inherent Softness | Enables faster cutting speeds and complex shapes |

| Natural Lubricity | Provides a smooth surface finish without polishing |

| Low Cutting Force | Lowers production costs and energy consumption |

Ready to leverage the superior machinability of PTFE for your precision components?

At KINTEK, we specialize in manufacturing high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision machining ensures your custom parts meet the tightest tolerances and most complex geometries, from prototypes to high-volume orders.

Contact us today to discuss your project and discover how our PTFE fabrication capabilities can optimize your production process and reduce costs.

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- In which types of industrial equipment is PTFE rod commonly used? Essential for Seals, Bearings & Valves

- What are PTFE rods and how are they manufactured? A Guide to Their Properties and Production

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- How are PTFE extruded rods applied in the food processing industry? Enhancing Hygiene and Efficiency