Yes, absolutely. PTFE rods are not only machinable but are specifically designed to be fabricated into complex shapes through machining. This is the primary method for creating custom PTFE parts because, unlike most thermoplastics, PTFE cannot be melted and injection molded.

The core reason for machining PTFE is its unique molecular structure; it does not have a true melt phase. This makes conventional machining methods like turning and milling the essential, and highly effective, process for transforming stock rods and sheets into precise, complex components.

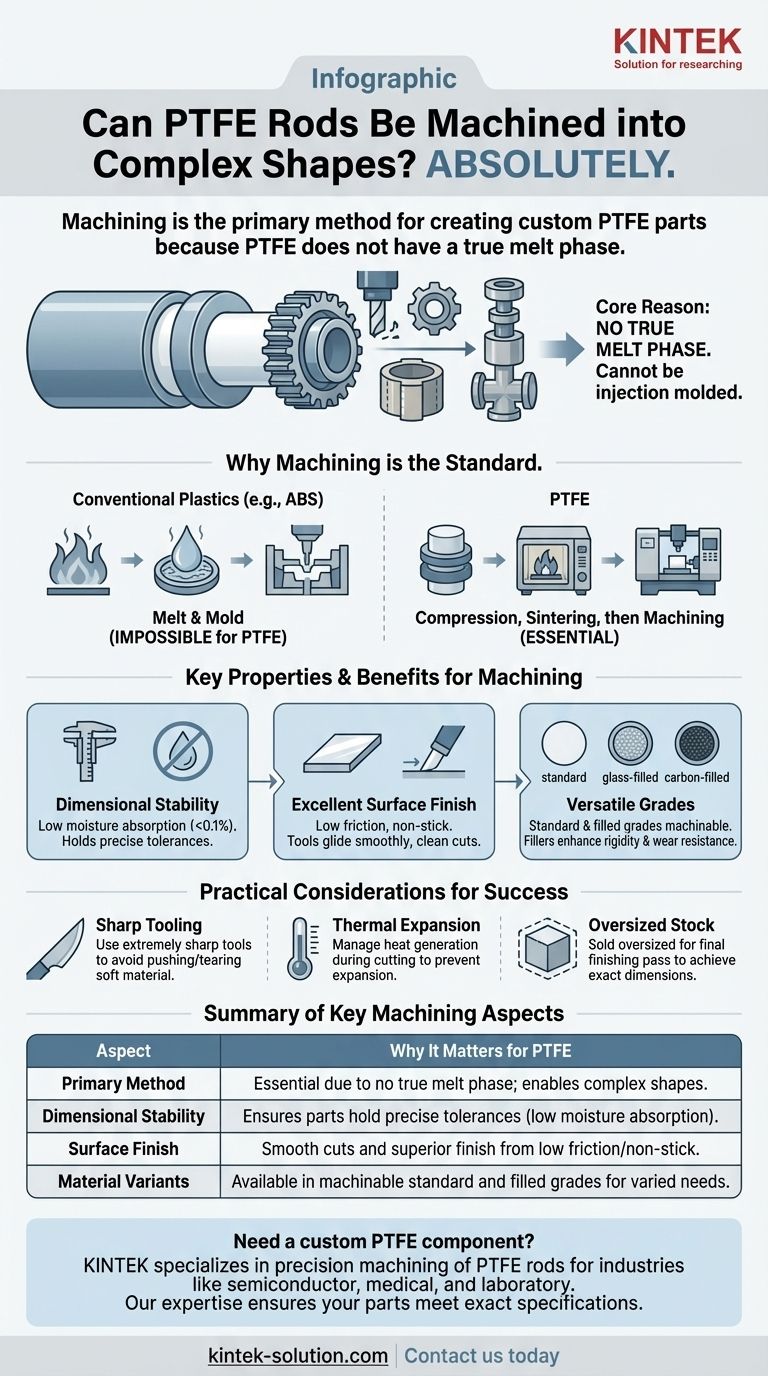

Why Machining is the Standard for PTFE

Understanding why PTFE is machined rather than molded is key to appreciating its role in engineering. The process is a direct result of its fundamental material properties.

A Material That Won't Melt

Most common plastics, like ABS or polycarbonate, can be heated until they become a liquid, injected into a mold, and then cooled to form a final shape. PTFE (Polytetrafluoroethylene) does not behave this way.

When heated, PTFE does not liquefy. Instead, it transitions into a gel-like state at high temperatures and loses its structural integrity. This makes melt-processing methods like injection molding impossible.

The Role of Sintering and Compression

To create stock shapes like rods or sheets, raw PTFE powder is first compressed into the desired form under immense pressure.

This compressed form, known as a "billet," is then heated in a controlled oven in a process called sintering. This fuses the PTFE particles together into a solid, dense, and machinable block.

Excellent Dimensional Stability

A key advantage of PTFE is its dimensional stability. The material does not easily warp or change shape due to temperature fluctuations or moisture absorption during the machining process.

This stability, combined with its low water absorption (below 0.1%), ensures that machined parts hold their intended tolerances with high precision.

Key Properties Influencing the Machining Process

Several of PTFE's famous characteristics make it particularly well-suited for machining, though they also require specific considerations.

Low Coefficient of Friction

PTFE is exceptionally "slippery." This low friction is beneficial during machining, as it allows cutting tools to glide smoothly across the material surface, often resulting in a superior surface finish.

Non-Adhesive Surface

The famous non-stick quality of PTFE also applies to the manufacturing floor. Material does not tend to build up on the cutting tool, which helps prevent imperfections and ensures a clean, continuous cut.

Handling Different Formulations

The references mention glass-filled PTFE, which is a common variant. Adding glass fibers or other fillers enhances properties like rigidity and wear resistance.

These filled grades are also readily machinable, though they can be more abrasive and may require harder, more durable cutting tools to achieve the best results.

Understanding the Practical Considerations

While easily machined, achieving optimal results with PTFE involves understanding its unique behavior.

Sold Oversized for a Reason

PTFE stock shapes are often intentionally manufactured to be slightly oversized. This is standard practice in the industry.

This extra material allows machinists to make a final "skimming" or finishing pass to achieve the exact final dimensions and a perfectly smooth surface.

The Need for Sharp Tooling

Because PTFE is a relatively soft, waxy material, using extremely sharp cutting tools is critical. Dull tools can tend to push or tear the material rather than shearing it cleanly, leading to poor surface finish and burrs.

Managing Thermal Expansion

While dimensionally stable against moisture, PTFE does have a relatively high rate of thermal expansion. It's important to manage heat generated during aggressive cutting operations to prevent the part from expanding and affecting final tolerances. Using coolant and appropriate feed rates are common solutions.

Making the Right Choice for Your Goal

PTFE is a highly versatile material for custom parts, provided its unique properties align with your application's needs.

- If your primary focus is chemical inertness and low friction: PTFE is an ideal candidate for machining custom seals, bearings, bushings, or valve components.

- If your primary focus is electrical insulation: Its high dielectric strength makes it perfect for creating custom high-frequency insulators, connectors, and test fixtures.

- If you require higher rigidity and wear resistance: A glass-filled or carbon-filled PTFE grade provides enhanced mechanical properties while retaining excellent machinability.

Ultimately, PTFE's unique combination of properties makes it a premier choice for creating high-performance, custom-machined components for demanding environments.

Summary Table:

| Key Machining Aspect | Why It Matters for PTFE |

|---|---|

| Primary Method | Machining is essential; PTFE cannot be injection molded due to its lack of a true melt phase. |

| Dimensional Stability | Low moisture absorption (<0.1%) and stability ensure parts hold precise tolerances. |

| Surface Finish | Low friction and non-stick properties allow for smooth cuts and superior finishes. |

| Material Variants | Standard and filled grades (e.g., glass-filled) are machinable, with filled grades offering enhanced rigidity. |

Need a custom PTFE component for your application?

At KINTEK, we specialize in precision machining of PTFE rods and sheets into complex shapes for industries like semiconductor, medical, and laboratory. Our expertise ensures your custom parts—from prototypes to high-volume orders—meet exact specifications for chemical resistance, electrical insulation, and low friction.

Contact us today to discuss your project and leverage our advanced fabrication capabilities!

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- What industrial applications utilize extruded PTFE rods? Key Uses in Chemical, Aerospace & More

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments

- How does PTFE rod perform in chemically harsh environments? Unmatched Chemical Resistance for Demanding Applications

- In which types of industrial equipment is PTFE rod commonly used? Essential for Seals, Bearings & Valves