In industrial settings, extruded Polytetrafluoroethylene (PTFE) rods are primarily machined into critical components like seals, gaskets, slide bearings, bushings, and electrical insulators. Their prevalence is due to a unique combination of properties that allow them to perform reliably in harsh environments where other materials would quickly fail.

The true value of an extruded PTFE rod is not just its form, but its function. It is a material of choice not for what it does, but for what it endures: extreme chemical exposure, high temperatures, and constant friction.

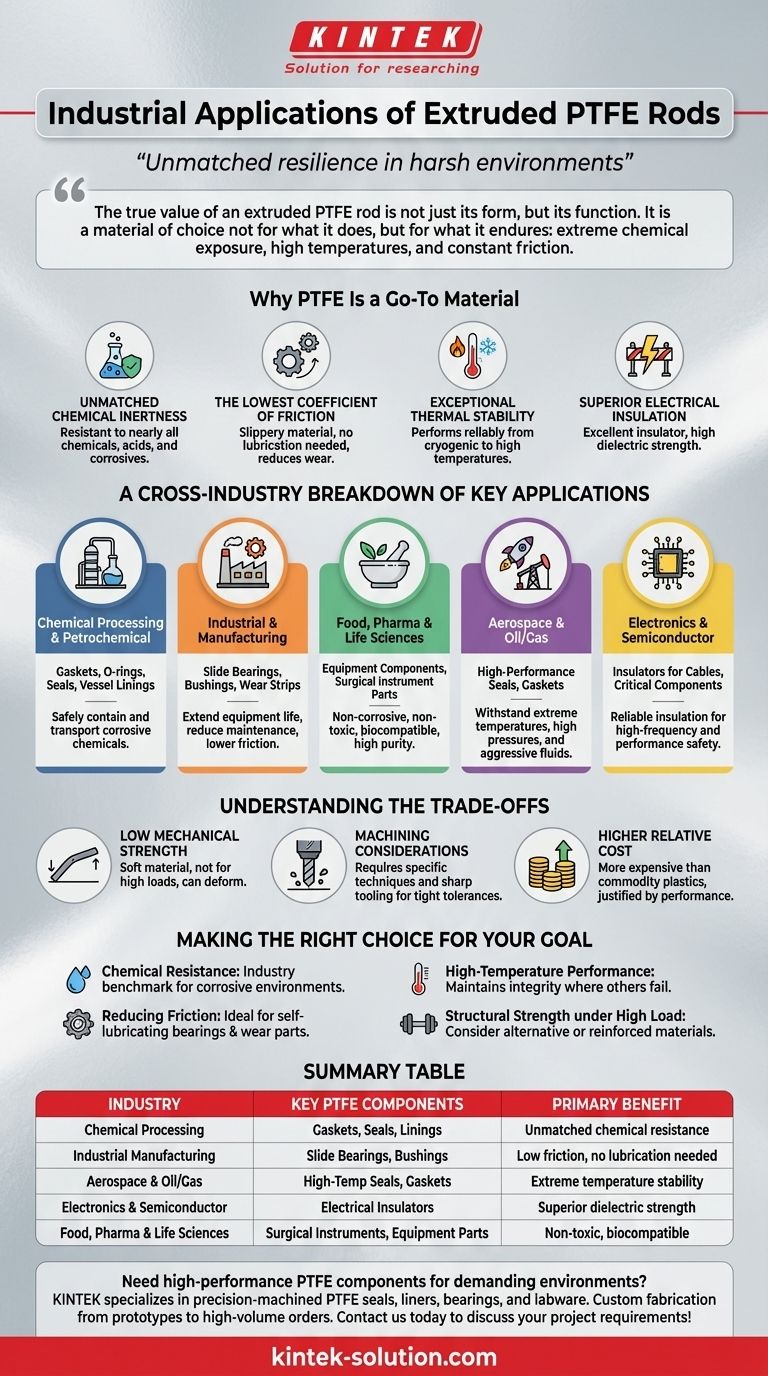

Why PTFE Is a Go-To Material for Demanding Environments

The utility of PTFE stems from a few fundamental material properties. Understanding these characteristics is key to seeing why it is so widely adopted across different industries.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, solvents, and corrosive agents. This includes everything from aggressive acids and oxidizing media to mineral oils and petrochemicals.

This property makes it indispensable for components that are in direct contact with harsh substances, ensuring system integrity and preventing contamination.

The Lowest Coefficient of Friction

Of any solid material known, PTFE has one of the lowest coefficients of friction. It is an inherently "slippery" material that requires no external lubrication.

This makes it the ideal choice for creating slide bearings, bushings, and wear strips in machinery, as it dramatically reduces friction, minimizes wear, and improves operational efficiency.

Exceptional Thermal Stability

PTFE performs reliably across an exceptionally wide range of temperatures. It maintains its properties in both cryogenic conditions and high-heat applications where many other polymers would degrade or melt.

This thermal resilience is crucial for applications in aerospace, oil and gas, and high-temperature chemical processing.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength. It does not conduct electricity, making it a safe and effective material for insulating wires, cables, and electronic components.

This is particularly valuable in the semiconductor and electronics industries, where reliable insulation is critical for performance and safety.

A Cross-Industry Breakdown of Key Applications

While the components are often similar (seals, bearings), their specific function varies significantly depending on the industry's unique challenges.

Chemical Processing & Petrochemical

In this sector, extruded PTFE rods are machined into gaskets, O-rings, seals, and vessel linings. Their purpose is to safely contain and transport highly corrosive chemicals without degrading.

Industrial & Manufacturing

Here, the focus is on reducing mechanical wear and friction. PTFE rods become slide bearings, bushings, and other low-friction components for machinery, extending the life of equipment and reducing maintenance needs.

Food, Pharma & Life Sciences

PTFE is non-corrosive, non-toxic, and often biocompatible. This allows it to be used for components in food and drink production equipment, parts for surgical instruments, and other medical devices where purity is paramount.

Aerospace & Oil/Gas

In these demanding fields, components made from PTFE rods serve as high-performance seals and gaskets. They must withstand extreme temperatures, high pressures, and aggressive fluids while maintaining their structural integrity.

Electronics & Semiconductor

The electrical insulating properties of PTFE are the main driver here. Rods are machined into insulators for high-frequency cables and critical components within the semiconductor manufacturing process.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of PTFE is essential for proper application and design.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load structural applications and can be susceptible to "creep" or deformation under sustained pressure.

Machining Considerations

While easily machined, its softness and thermal properties require specific techniques and sharp tooling to achieve tight dimensional tolerances without causing the material to deform.

Higher Relative Cost

Compared to commodity plastics like nylon or acetal, PTFE is more expensive. Its use is therefore typically justified in performance-critical applications where its unique properties are a strict requirement.

Making the Right Choice for Your Goal

Your decision to use PTFE should be driven by the specific problem you need to solve.

- If your primary focus is chemical resistance: PTFE is the industry benchmark for seals, gaskets, and linings in corrosive environments.

- If your primary focus is reducing friction: It is an ideal choice for self-lubricating slide bearings, bushings, and wear components.

- If your primary focus is high-temperature performance: PTFE maintains its integrity in applications where most other plastics would fail.

- If your primary focus is structural strength under high load: You should consider alternative materials or reinforced grades of PTFE.

Ultimately, selecting PTFE is a decision to prioritize resilience and reliability in the most challenging operational conditions.

Summary Table:

| Industry | Key PTFE Components | Primary Benefit |

|---|---|---|

| Chemical Processing | Gaskets, Seals, Linings | Unmatched chemical resistance |

| Industrial Manufacturing | Slide Bearings, Bushings | Low friction, no lubrication needed |

| Aerospace & Oil/Gas | High-Temp Seals, Gaskets | Extreme temperature stability |

| Electronics & Semiconductor | Electrical Insulators | Superior dielectric strength |

| Food, Pharma & Life Sciences | Surgical Instruments, Equipment Parts | Non-toxic, biocompatible |

Need high-performance PTFE components for demanding environments? KINTEK specializes in precision-machined PTFE seals, liners, bearings, and labware for semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders, ensuring your components withstand extreme chemicals, temperatures, and friction. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- In which types of industrial equipment is PTFE rod commonly used? Essential for Seals, Bearings & Valves

- What industries commonly use PTFE extruded rods? Key Applications in High-Performance Sectors