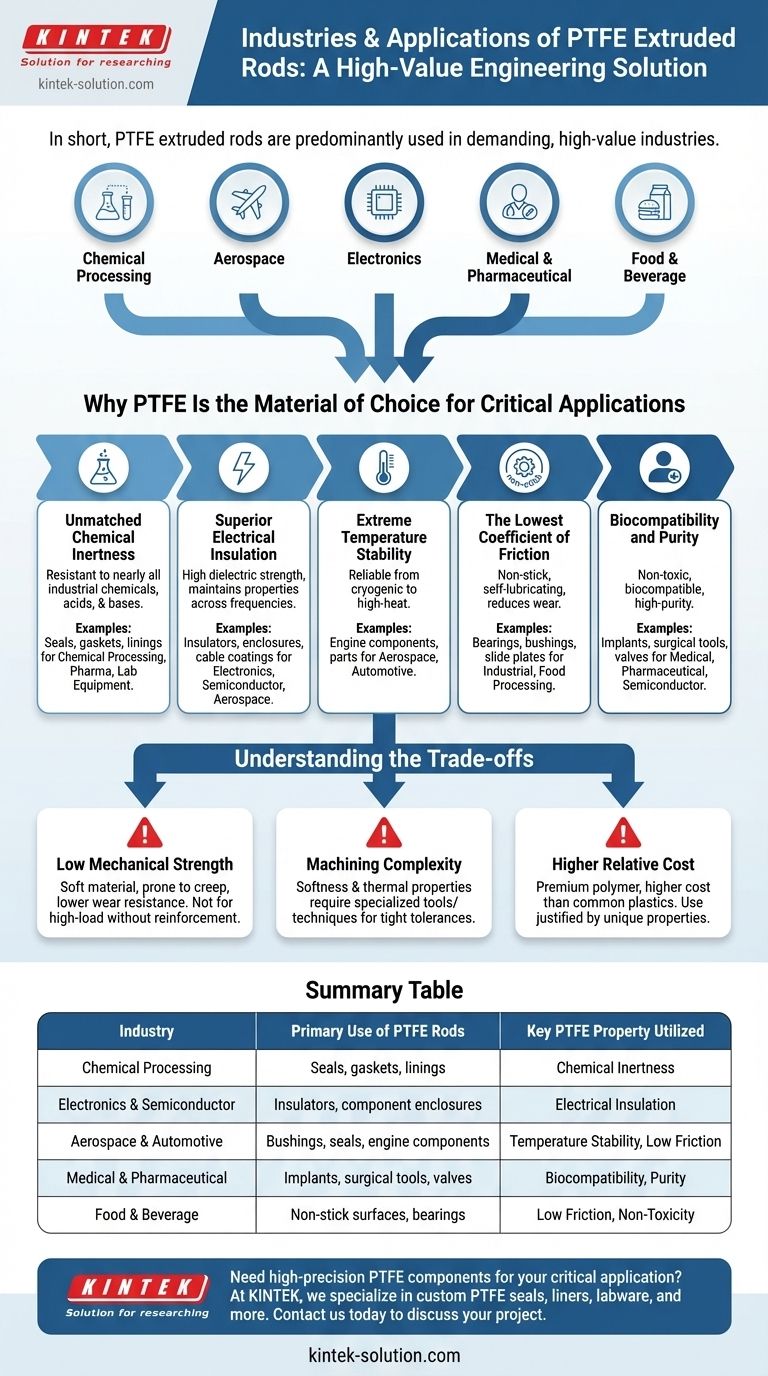

In short, PTFE extruded rods are predominantly used in demanding, high-value industries. These include chemical processing, aerospace, electronics, medical and pharmaceutical manufacturing, and the food and beverage sector. Its adoption is driven by a unique set of properties that make it one of the most versatile and reliable engineering plastics available for critical components.

The widespread use of PTFE across these distinct industries is not a matter of convenience; it is a solution to fundamental engineering challenges. Its combination of near-total chemical inertness, excellent electrical insulation, and an extremely low coefficient of friction makes it the default material for components that simply cannot fail in harsh environments.

Why PTFE Is the Material of Choice for Critical Applications

The value of PTFE (Polytetrafluoroethylene) is not in a single feature but in its powerful combination of properties. Each characteristic directly addresses a critical need in specific industrial applications.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and bases. This makes it an essential material for any application involving corrosive substances.

This property is why it's a cornerstone of the chemical processing, pharmaceutical, and laboratory equipment industries for parts like seals, gaskets, and linings.

Superior Electrical Insulation

PTFE has an exceptionally high dielectric strength and is a fantastic electrical insulator. It maintains these properties across a wide range of frequencies and temperatures.

This makes it indispensable in the electronics, semiconductor, and aerospace industries for creating high-performance insulators, enclosures for sensitive components, and cable coatings.

Extreme Temperature Stability

PTFE performs reliably across a vast temperature range, from cryogenic lows to high-heat applications. This stability ensures components do not become brittle or deform under thermal stress.

This resilience is critical for parts used in aerospace and automotive engines, where components must endure rapid and extreme temperature fluctuations.

The Lowest Coefficient of Friction

PTFE has one of the lowest friction coefficients of any known solid material, giving it a characteristic "non-stick" or self-lubricating quality.

This is the key to its use in industrial bearings, bushings, and slide plates, where it reduces wear and eliminates the need for external lubrication. It's also the reason for its use in food processing equipment to prevent sticking.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it can be used in contact with the human body without causing an adverse reaction. It is also suitable for high-purity fluid transfer.

These traits are vital for the medical industry, where it is used for implants and surgical equipment, and for the semiconductor and pharmaceutical industries for high-purity valves and tubing.

Understanding the Trade-offs

No material is perfect. A clear understanding of PTFE's limitations is essential for proper application and to avoid common pitfalls.

Low Mechanical Strength

PTFE is a relatively soft material. It can be prone to "creep," or deformation under a sustained load, and has lower wear resistance compared to harder plastics.

This means it is generally not suitable for high-load structural components without reinforcement.

Machining Complexity

While PTFE is readily machinable, its softness and thermal properties require specialized tools and techniques to hold tight tolerances and achieve a fine surface finish.

Poor machining can compromise the integrity of the final part, making expertise crucial for manufacturing precision components.

Higher Relative Cost

PTFE is a premium-performance polymer. Its cost is higher than that of common plastics like nylon or acetal.

Its use is therefore typically justified in applications where its unique properties are a strict requirement and component failure is not an option.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary engineering goal. PTFE is an exceptional problem-solver when used in the right context.

- If your primary focus is chemical resistance and purity: PTFE is the industry standard for components in chemical processing, pharmaceutical, and semiconductor applications.

- If your primary focus is electrical insulation: Its superior dielectric properties make it a top choice for high-frequency electronics and aerospace wiring.

- If your primary focus is low-friction, self-lubricating parts: PTFE is ideal for creating high-performance bearings, non-stick surfaces, and slide plates.

- If your primary focus is cost-sensitive structural parts: You should evaluate other engineering plastics, as PTFE's softness and higher cost may be prohibitive.

By understanding these core properties and trade-offs, you can confidently determine where PTFE extruded rods provide a critical engineering advantage.

Summary Table:

| Industry | Primary Use of PTFE Rods | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Seals, gaskets, linings | Chemical Inertness |

| Electronics & Semiconductor | Insulators, component enclosures | Electrical Insulation |

| Aerospace & Automotive | Bushings, seals, engine components | Temperature Stability, Low Friction |

| Medical & Pharmaceutical | Implants, surgical tools, valves | Biocompatibility, Purity |

| Food & Beverage | Non-stick surfaces, bearings | Low Friction, Non-Toxicity |

Need high-precision PTFE components for your critical application?

At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your components meet the highest standards for performance and reliability, from prototypes to high-volume orders.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance your application's performance and durability.

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the machining advantages of PTFE rod? Achieve Cost-Effective, Complex Parts

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments

- What are PTFE rods and how are they manufactured? A Guide to Their Properties and Production

- How does PTFE rod perform in chemically harsh environments? Unmatched Chemical Resistance for Demanding Applications

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.