In chemically harsh environments, PTFE rod delivers exceptional performance. It is one of the most chemically resistant and inert polymers available, making it a benchmark material for applications involving aggressive substances. Its non-reactive nature ensures it does not degrade, swell, or weaken when exposed to a vast spectrum of acids, bases, solvents, and corrosive fluids.

The core reason for PTFE's reliability is its fundamental chemical inertness. This property means it simply does not react with its surroundings, ensuring components maintain their integrity and operational efficiency where nearly all other materials would fail.

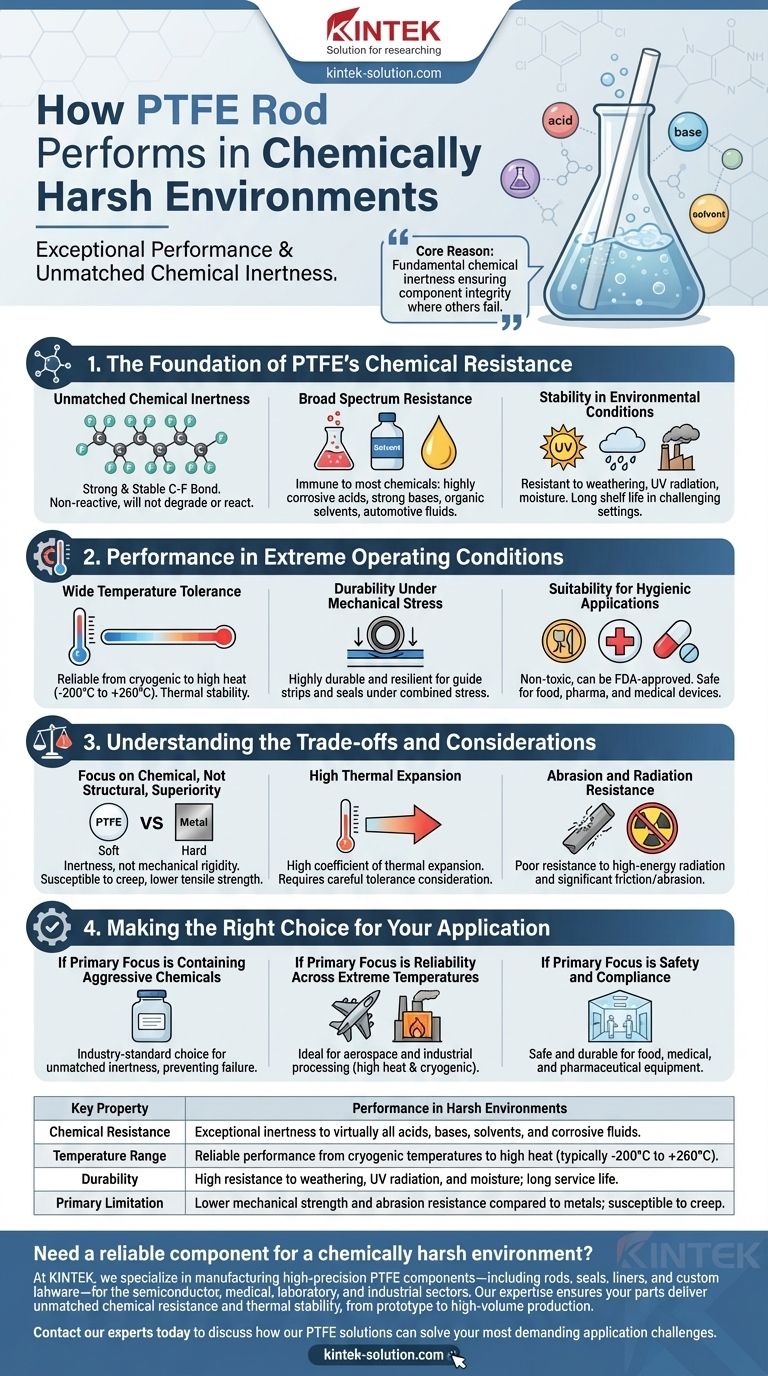

The Foundation of PTFE's Chemical Resistance

PTFE's performance is not just good; it is often the standard against which other materials are measured in corrosive settings. This reputation is built on a few key molecular properties.

Unmatched Chemical Inertness

The carbon-fluorine bond in the Polytetrafluoroethylene (PTFE) structure is incredibly strong and stable. This makes the material non-reactive.

It will not degrade or react with the substances it contacts, preserving its physical properties over long periods.

Broad Spectrum Resistance

PTFE is virtually immune to most chemicals, including highly corrosive acids, strong bases, and organic solvents.

This resistance extends to automotive fluids like diesel, gasoline, and chemically aggressive oils, making it a superior choice for seals and components in demanding vehicle systems.

Stability in Environmental Conditions

Beyond direct chemical contact, PTFE is highly resistant to weathering and environmental contaminants.

It is not affected by harsh weather, UV radiation, or moisture, allowing it to maintain its properties and have a long shelf life even in challenging outdoor or industrial settings.

Performance in Extreme Operating Conditions

A material's utility in a harsh environment often depends on more than just chemical resistance. PTFE excels by combining its inertness with tolerance for other extreme conditions.

Wide Temperature Tolerance

PTFE performs reliably across an exceptionally wide range of temperatures.

This thermal stability makes it suitable for everything from high-temperature chemical processing plants to the extreme cold and vacuum of aerospace applications.

Durability Under Mechanical Stress

While not primarily known for its mechanical strength compared to metals, PTFE is highly durable and resilient in its intended applications.

Components like guide strips and seals benefit from its combined resistance to chemicals, temperature, and mechanical stress, ensuring reliable operation.

Suitability for Hygienic Applications

PTFE is non-toxic and can be manufactured to be FDA-approved.

This makes it a safe and compliant choice for industries like food processing, pharmaceuticals, and medical devices, where chemical resistance and hygiene are equally critical.

Understanding the Trade-offs and Considerations

While PTFE's chemical performance is nearly unparalleled, selecting it requires a holistic view of the application's demands. Its unique strengths come with specific trade-offs.

Focus on Chemical, Not Structural, Superiority

PTFE's primary advantage is its inertness, not its mechanical rigidity or hardness. It is a relatively soft material susceptible to creep under load and has lower tensile strength than many engineering plastics or metals.

It should be chosen for its chemical and thermal properties, not for applications requiring high structural load-bearing capacity without reinforcement.

High Thermal Expansion

Compared to metals and other polymers, PTFE has a high coefficient of thermal expansion.

Design engineers must account for this, as components can change dimensions significantly with temperature fluctuations. This is a critical consideration for parts requiring tight tolerances.

Abrasion and Radiation Resistance

PTFE has relatively poor resistance to high-energy radiation, which can cause its molecular structure to break down.

It is also not ideal for high-wear applications involving significant friction or abrasion unless it is filled with other materials (e.g., glass, carbon) to improve these properties.

Making the Right Choice for Your Application

Selecting PTFE rod should be a deliberate decision based on the primary challenge you need to solve.

- If your primary focus is containing highly aggressive chemicals: PTFE is the industry-standard choice due to its unmatched inertness, preventing component failure and contamination.

- If your primary focus is reliability across extreme temperatures: PTFE's ability to maintain its properties in both high-heat and cryogenic conditions makes it ideal for aerospace and industrial processing.

- If your primary focus is safety and compliance in a clean environment: Its non-toxic and FDA-approved qualities make it a safe and durable material for food, medical, and pharmaceutical equipment.

Ultimately, PTFE rod provides a level of chemical resilience that makes it the definitive solution for the most demanding environments.

Summary Table:

| Key Property | Performance in Harsh Environments |

|---|---|

| Chemical Resistance | Exceptional inertness to virtually all acids, bases, solvents, and corrosive fluids. |

| Temperature Range | Reliable performance from cryogenic temperatures to high heat (typically -200°C to +260°C). |

| Durability | High resistance to weathering, UV radiation, and moisture; long service life. |

| Primary Limitation | Lower mechanical strength and abrasion resistance compared to metals; susceptible to creep. |

Need a reliable component for a chemically harsh environment?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including rods, seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver unmatched chemical resistance and thermal stability, from prototype to high-volume production.

Contact our experts today to discuss how our PTFE solutions can solve your most demanding application challenges.

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial applications utilize extruded PTFE rods? Key Uses in Chemical, Aerospace & More

- What are the machining advantages of PTFE rod? Achieve Cost-Effective, Complex Parts

- What industries commonly use PTFE extruded rods? Key Applications in High-Performance Sectors

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments