In short, PTFE rod is a critical component in industrial equipment where extreme chemical resistance, low friction, and high-temperature stability are required. It is most commonly machined into parts for pumps, valves, bearings, and seals, particularly within the chemical processing, aerospace, and electronics industries.

The widespread use of PTFE rod is not due to a single feature, but its unique combination of properties. It acts as a high-performance problem-solver in environments where conventional materials would quickly fail due to corrosion, friction, or heat.

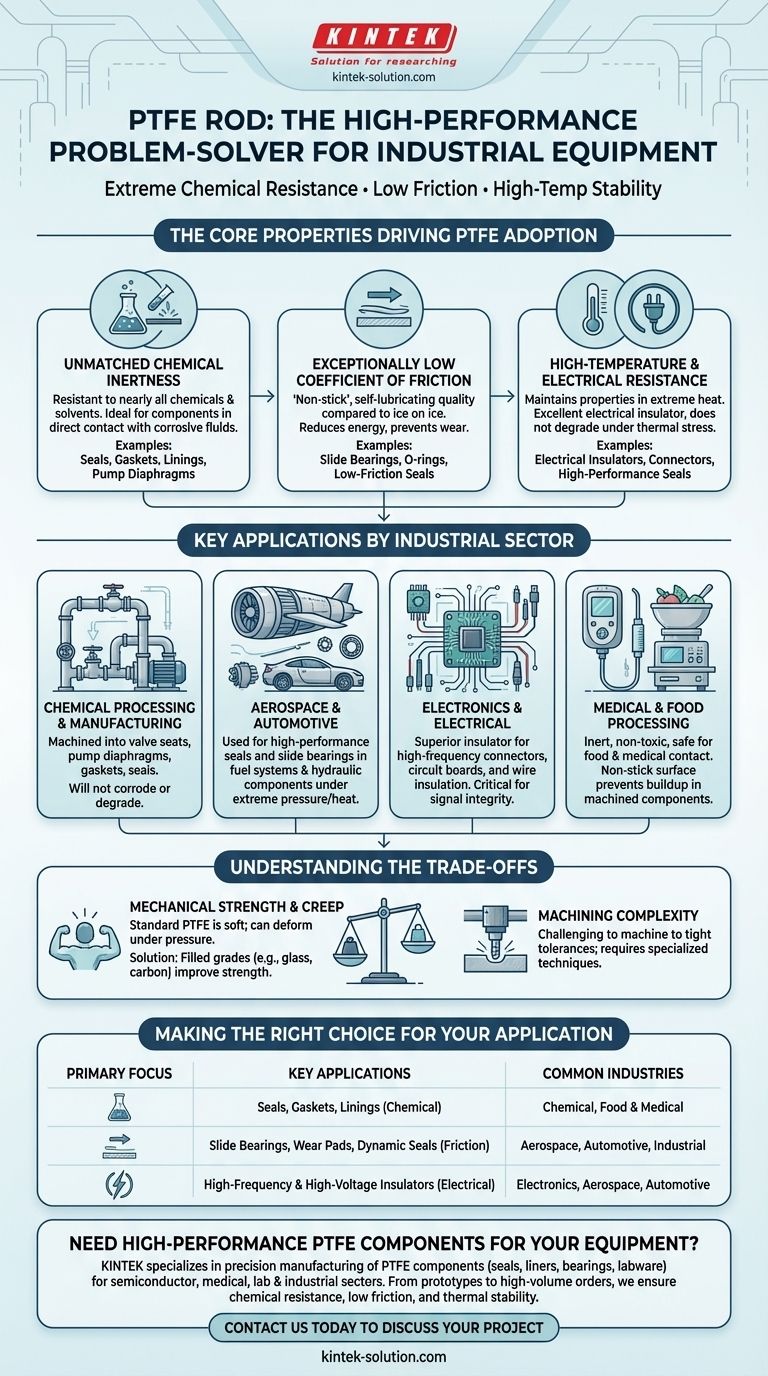

The Core Properties Driving PTFE Adoption

To understand where PTFE rod is used, you must first understand why it is chosen. Three core properties make it indispensable in demanding industrial settings.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This makes it the material of choice for components that are in direct contact with corrosive fluids.

This property is why it's heavily used for seals, gaskets, and linings in chemical pumps and valve bodies. It ensures the integrity of the equipment and prevents contamination.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" or self-lubricating quality is invaluable for moving parts.

This is the primary reason it's used to manufacture slide bearings, O-rings, and low-friction seals. These components reduce energy consumption and prevent wear without external lubrication.

High-Temperature and Electrical Resistance

PTFE maintains its properties across a wide temperature range and is an excellent electrical insulator. It does not degrade under thermal stress and can isolate high-voltage components effectively.

This makes it essential for creating electrical insulators, connectors, and high-performance seals used in aerospace, automotive, and electronics manufacturing where both heat and electrical isolation are concerns.

Key Applications by Industrial Sector

Different industries leverage specific properties of PTFE to solve their unique challenges.

Chemical Processing and Manufacturing

In this sector, equipment must endure constant exposure to harsh materials. PTFE rod is machined into valve seats, pump diaphragms, gaskets, and seals that will not corrode or degrade, ensuring operational safety and longevity.

Aerospace and Automotive

Reliability is paramount in these industries. PTFE is used for high-performance seals and slide bearings in fuel systems and hydraulic components that must function reliably under extreme temperatures and pressures.

Electronics and Electrical

The excellent dielectric properties of PTFE make it a superior insulator. It is used for insulators in high-frequency connectors, circuit boards, and wire insulation, especially in high-performance applications where signal integrity is critical.

Medical and Food Processing

Because PTFE is inert and non-toxic, it is safe for contact with food products and for use in medical devices. Its non-stick surface prevents buildup, making it ideal for machined components in processing equipment and even some medical implants.

Understanding the Trade-offs

While highly effective, PTFE is not universally applicable. Understanding its limitations is key to using it correctly.

Mechanical Strength and Creep

Standard, unfilled PTFE is a relatively soft material. Under sustained pressure (especially at elevated temperatures), it can deform or "creep." For structural applications requiring high rigidity, filled grades of PTFE (such as glass-filled or carbon-filled) are used to improve mechanical strength.

Machining Complexity

As a soft material, PTFE can be challenging to machine to very tight tolerances. It requires sharp tools and specific techniques to avoid deformation and achieve a clean finish, which can impact manufacturing costs.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is chemical resistance: PTFE is an industry-standard choice for seals, gaskets, and linings that will handle corrosive fluids.

- If your primary focus is low friction: It is the ideal material for creating self-lubricating slide bearings, wear pads, and dynamic seals.

- If your primary focus is electrical insulation: PTFE excels in high-frequency and high-voltage applications where other insulators would fail.

Ultimately, PTFE rod is the go-to material for machining high-performance components that solve critical engineering problems in the most demanding environments.

Summary Table:

| Primary Property | Key Applications | Common Industries |

|---|---|---|

| Chemical Inertness | Seals, Gaskets, Linings | Chemical Processing, Food & Medical |

| Low Friction | Bearings, O-rings, Dynamic Seals | Aerospace, Automotive, Industrial |

| High-Temp & Electrical Resistance | Insulators, Connectors, High-Performance Seals | Electronics, Aerospace, Automotive |

Need high-performance PTFE components for your equipment?

At KINTEK, we specialize in precision manufacturing of PTFE components—including seals, liners, bearings, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures parts that meet the strictest demands for chemical resistance, low friction, and thermal stability.

Contact us today to discuss your project and discover how our custom PTFE solutions can enhance your equipment's reliability and performance.

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments

- How are PTFE extruded rods applied in the food processing industry? Enhancing Hygiene and Efficiency

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- What are the machining advantages of PTFE rod? Achieve Cost-Effective, Complex Parts

- What industries commonly use PTFE extruded rods? Key Applications in High-Performance Sectors