At its core, a PTFE seal is a high-performance sealing solution engineered from Polytetrafluoroethylene, a remarkably resilient synthetic fluoropolymer. These seals are specifically designed to prevent leakage and maintain integrity in extreme operating conditions where conventional materials would quickly degrade. Their exceptional performance stems from a unique combination of extreme chemical resistance, a vast temperature tolerance, and an incredibly low coefficient of friction.

The true value of a PTFE seal is not just its durability, but its ability to provide a reliable sealing solution in environments so hostile—chemically, thermally, or mechanically—that they render most other materials completely ineffective.

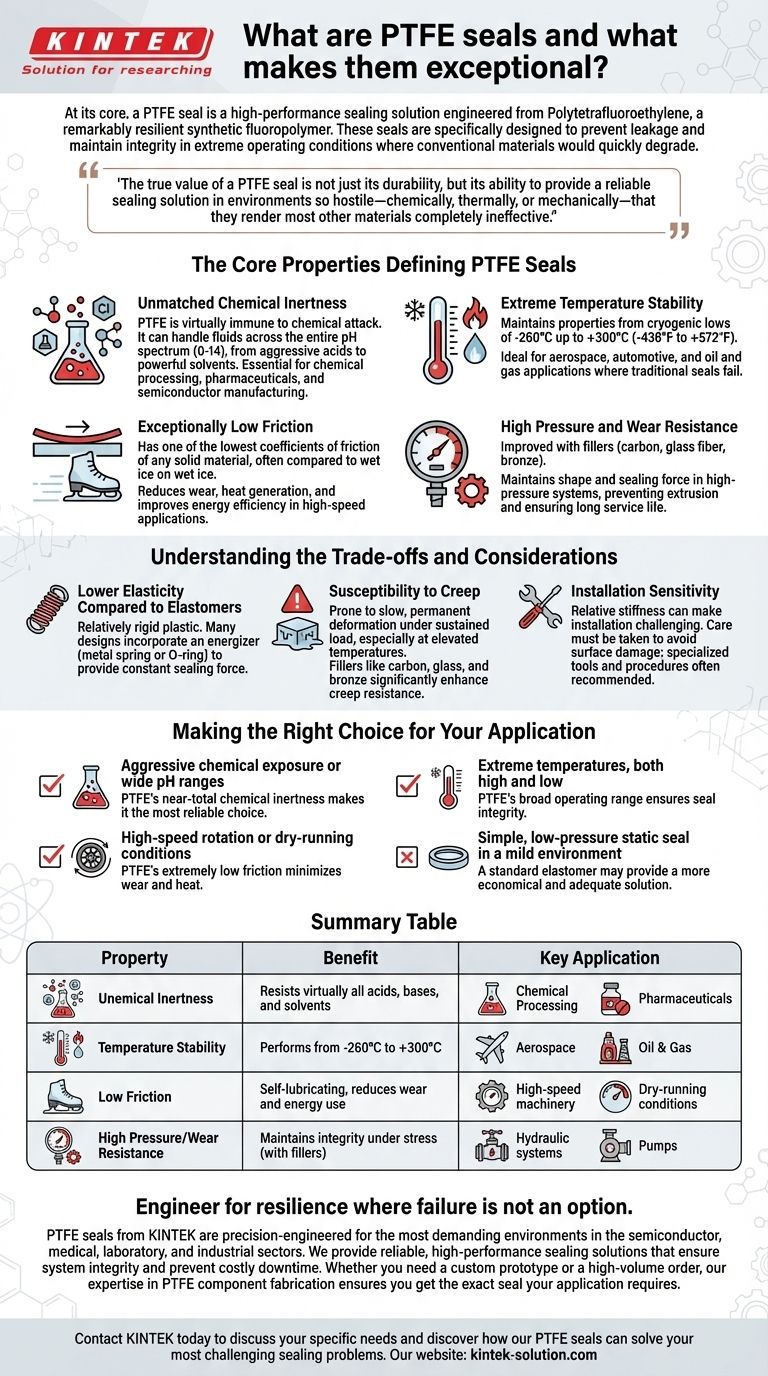

The Core Properties Defining PTFE Seals

The unique molecular structure of PTFE, built on a strong carbon-fluorine bond, gives rise to a set of properties that make it a premier material for challenging sealing applications. These characteristics are often enhanced by adding fillers like carbon, glass fiber, or bronze powder.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It can handle fluids across the entire pH spectrum (0-14), from aggressive acids to powerful solvents.

This makes it an essential material in industries like chemical processing, pharmaceuticals, and semiconductor manufacturing, where seal degradation would lead to contamination and catastrophic failure.

Extreme Temperature Stability

PTFE seals maintain their properties across an exceptionally wide temperature range, typically from cryogenic lows of -260°C up to +300°C (-436°F to +572°F).

Where traditional rubber or elastomer seals would become brittle and crack in the cold or melt in the heat, PTFE remains stable and effective, making it ideal for aerospace, automotive, and oil and gas applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" or self-lubricating property is a significant advantage.

It reduces wear and tear on moving parts, minimizes heat generation in high-speed applications, and improves overall energy efficiency. This is critical for reciprocating pistons and rotating shafts that may operate with minimal lubrication.

High Pressure and Wear Resistance

While pure PTFE is robust, its mechanical strength and wear resistance are significantly improved with the addition of fillers.

This allows PTFE seals to maintain their shape and sealing force in high-pressure systems, preventing extrusion and ensuring a long, reliable service life even under demanding mechanical stress.

Understanding the Trade-offs and Considerations

While PTFE's properties are exceptional, it's not a universal solution. Understanding its inherent trade-offs is crucial for proper application and design.

Lower Elasticity Compared to Elastomers

PTFE is a relatively rigid plastic, not a flexible elastomer like rubber. It lacks the "bounce-back" or memory of materials like nitrile or Viton.

Because of this, many PTFE seal designs incorporate an energizer, such as a metal spring or an O-ring, to provide a constant sealing force and compensate for the material's lower elasticity.

Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, pure PTFE can be prone to "creep," a slow, permanent deformation.

This is a primary reason fillers are so critical. Materials like carbon, glass, and bronze significantly enhance the seal's resistance to creep, ensuring it maintains its shape and integrity over time.

Installation Sensitivity

The relative stiffness of PTFE can make installation more challenging than with highly flexible rubber seals.

Care must be taken to avoid scratching or gouging the seal during installation, as any surface damage can create a potential leak path. Specialized tools and procedures are often recommended.

Making the Right Choice for Your Application

Selecting the correct seal material is about matching its properties to the demands of the operating environment.

- If your primary focus is aggressive chemical exposure or wide pH ranges: PTFE's near-total chemical inertness makes it the most reliable choice.

- If your primary focus is high-speed rotation or dry-running conditions: PTFE's extremely low friction minimizes wear and heat, vastly outperforming traditional elastomers.

- If your primary focus is extreme temperatures, both high and low: PTFE's broad operating range ensures seal integrity where other materials would fail.

- If your primary focus is a simple, low-pressure static seal in a mild environment: A standard elastomer may provide a more economical and perfectly adequate solution.

Ultimately, choosing a PTFE seal is a decision to engineer for resilience in applications where failure is not an option.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents | Chemical Processing, Pharmaceuticals |

| Temperature Stability | Performs from -260°C to +300°C | Aerospace, Oil & Gas |

| Low Friction | Self-lubricating, reduces wear and energy use | High-speed machinery, Dry-running conditions |

| High Pressure/Wear Resistance | Maintains integrity under stress (with fillers) | Hydraulic systems, Pumps |

Engineer for resilience where failure is not an option.

PTFE seals from KINTEK are precision-engineered for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. We provide reliable, high-performance sealing solutions that ensure system integrity and prevent costly downtime.

Whether you need a custom prototype or a high-volume order, our expertise in PTFE component fabrication ensures you get the exact seal your application requires.

Contact KINTEK today to discuss your specific needs and discover how our PTFE seals can solve your most challenging sealing problems.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals