At its core, a PTFE lined butterfly valve is a quarter-turn valve specifically designed for corrosive and high-purity applications. It uses a disc rotating within a pipe to control flow, but its defining feature is a liner made of Polytetrafluoroethylene (PTFE), also known as Teflon. This chemically inert liner completely isolates the valve's metal body from the process fluid, preventing corrosion and ensuring product purity.

The crucial takeaway is that the PTFE liner is not an add-on; it is the central design feature. This valve exists to solve the problem of safely handling aggressive chemicals or sensitive media that would destroy or be contaminated by a standard metal valve.

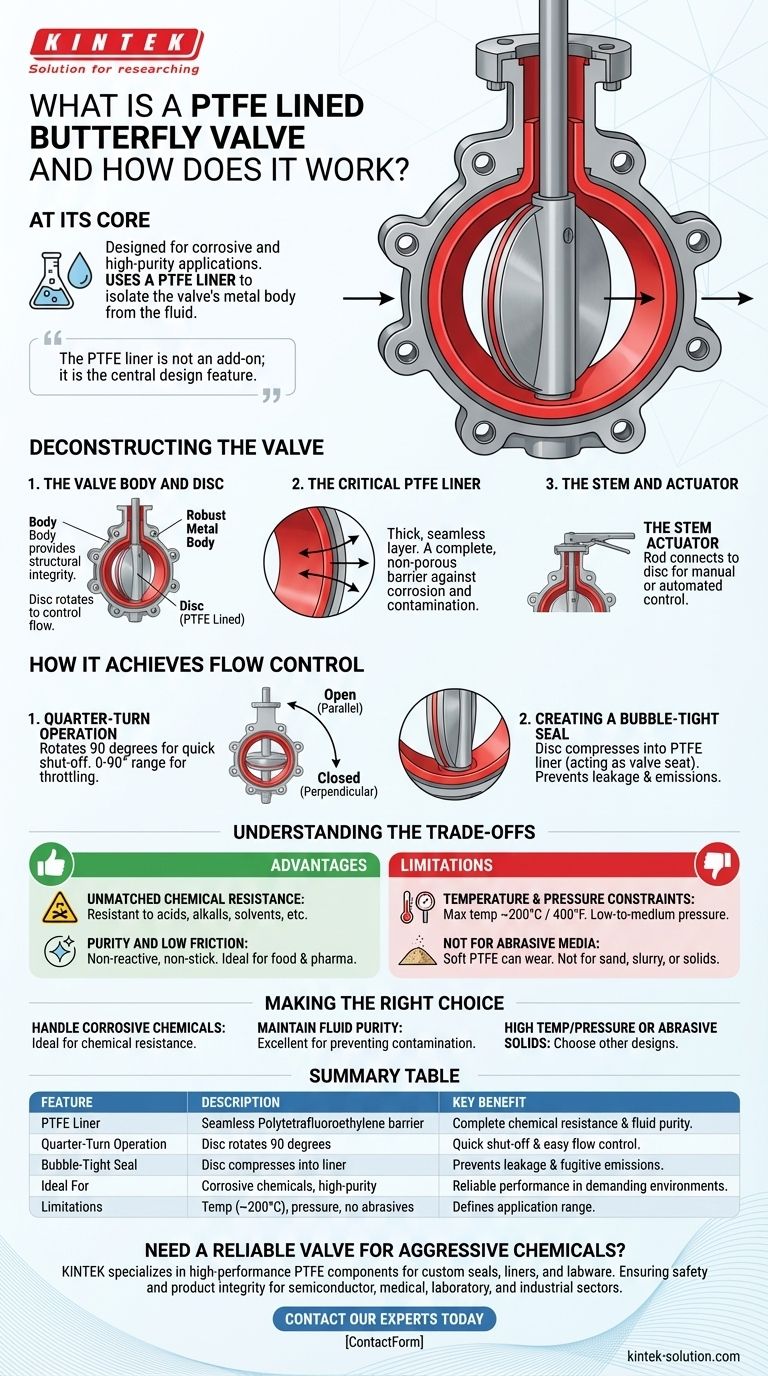

Deconstructing the PTFE Lined Butterfly Valve

To understand how this valve works, we must first examine its key components. Each part is engineered to work in concert, with the PTFE liner being the most critical element.

The Valve Body and Disc

The outer body provides the structural integrity of the valve. It is typically made from robust and cost-effective materials like carbon steel or stainless steel to handle pipeline pressures and external stresses.

Inside the body sits the disc, or "butterfly." This is the component that rotates to block or allow flow. The disc itself is often a metal casting that is then encapsulated or lined with PTFE.

The Critical PTFE Liner

The heart of the valve is the PTFE liner. This is a thick, seamless layer of polytetrafluoroethylene that is molded to fit the entire internal surface of the valve body.

This liner serves as a complete, non-porous barrier. It ensures that the aggressive or high-purity fluid passing through the valve only ever comes into contact with the chemically inert PTFE, never the metal body or stem. This prevents both corrosion of the valve and contamination of the fluid.

The Stem and Actuator

A rod, known as the stem, passes through the valve body and connects to the disc. The top of the stem extends outside the valve and connects to an actuator.

This actuator can be a simple manual handle for manual operation or an automated pneumatic or electric actuator for remote or automated control.

How It Achieves Flow Control

The valve's operation is based on a simple and effective mechanical principle, allowing it to serve as both a shutoff device and a throttling controller.

The Quarter-Turn Operation

A butterfly valve operates on a quick shut-off principle. Turning the actuator rotates the stem and disc by 90 degrees (a quarter turn).

When the disc is positioned perpendicular to the flow direction, the valve is fully closed. When the disc is rotated to be parallel with the flow, the valve is fully open, offering minimal resistance. Positions in between these two extremes can be used to regulate or "throttle" the flow rate.

Creating a Bubble-Tight Seal

The PTFE liner also functions as the valve seat. When the valve is closed, the outer edge of the disc presses firmly into the resilient PTFE liner.

This compression creates an exceptionally effective, bubble-tight seal. This is critical for preventing internal leakage within the system and for eliminating fugitive emissions—leaks of hazardous media from the valve into the atmosphere.

Understanding the Trade-offs

While highly effective, PTFE lined valves are a specialized tool. Understanding their limitations is as important as knowing their strengths.

Primary Advantage: Unmatched Chemical Resistance

This is the valve's main purpose. PTFE is resistant to nearly all acids, alkalis, solvents, and other corrosive chemicals, making it the default choice for the chemical processing industry.

Advantage: Purity and Low Friction

Because PTFE is non-reactive and non-stick, it is ideal for applications where fluid purity is essential, such as in pharmaceutical and food production. Its low-friction surface also minimizes pressure drop and reduces wear from fluid flow.

Limitation: Temperature and Pressure Constraints

PTFE has operational limits. While it performs well at moderately high temperatures (typically up to ~200°C / 400°F), it is not suitable for high-temperature steam or other applications where a metal-seated valve would be required. Similarly, they are generally used in low-to-medium pressure systems.

Limitation: Not for Abrasive Media

PTFE is a relatively soft material. These valves are not recommended for services containing abrasive particles, such as sand, slurry, or other solids, as the abrasive media can quickly wear away the liner and compromise the seal.

Making the Right Choice for Your Application

Selecting the correct valve requires matching the valve's capabilities to your primary operational goal.

- If your primary focus is handling corrosive or aggressive chemicals: This is the ideal valve. Its inert liner provides the most reliable protection against chemical attack.

- If your primary focus is maintaining fluid purity: This is an excellent choice. The non-reactive, non-stick PTFE surface prevents contamination of the process media.

- If your primary focus is high temperature, high pressure, or abrasive solids: You should look to other designs, such as a high-performance or metal-seated butterfly valve.

Ultimately, choosing a PTFE lined butterfly valve is a decision to prioritize chemical compatibility and purity above all other performance metrics.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| PTFE Liner | Seamless Polytetrafluoroethylene barrier inside the valve body. | Complete chemical resistance and fluid purity. |

| Quarter-Turn Operation | Disc rotates 90 degrees to open/close or throttle flow. | Quick shut-off and easy flow control. |

| Bubble-Tight Seal | Disc compresses into the PTFE liner when closed. | Prevents internal leakage and fugitive emissions. |

| Ideal For | Corrosive chemicals, acids, alkalis, high-purity applications. | Reliable performance in demanding environments. |

| Limitations | Temperature (~200°C max), pressure, and not for abrasive media. | Defines the valve's specific application range. |

Need a reliable valve for aggressive chemicals or high-purity processes?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals, liners, and labware. Our precision production ensures your equipment handles corrosive media safely and maintains product integrity.

Whether you need a standard solution or a custom-fabricated valve component for the semiconductor, medical, laboratory, or industrial sectors, we can deliver from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What temperature can heat-resistant Teflon sheets withstand? Up to 500°F for Reliable Performance

- What are the advantages of PTFE-coated O-rings compared to FFKM materials? Lower Cost vs. Ultimate Performance

- What material properties make PTFE suitable for oil seals? Superior Performance in Extreme Conditions

- How does PTFE's low coefficient of friction affect its machining process? Balancing Clean Cuts with Material Distortion

- What are the benefits of glass-filled PTFE sheet? Achieve Superior Strength and Wear Resistance

- What makes PTFE expansion bellows suitable for aerospace applications? Unmatched Reliability in Extreme Environments

- What are the different machining processes suitable for Teflon/PTFE? Master Precision for Soft Materials

- Why are PTFE O-rings preferred for sealing systems? Superior Chemical & Thermal Resistance