The primary advantage of PTFE-coated O-rings is their significantly lower cost when compared to solid FFKM (perfluoroelastomer) materials. This makes them a compelling economic alternative for applications where the absolute highest levels of performance are not a strict requirement.

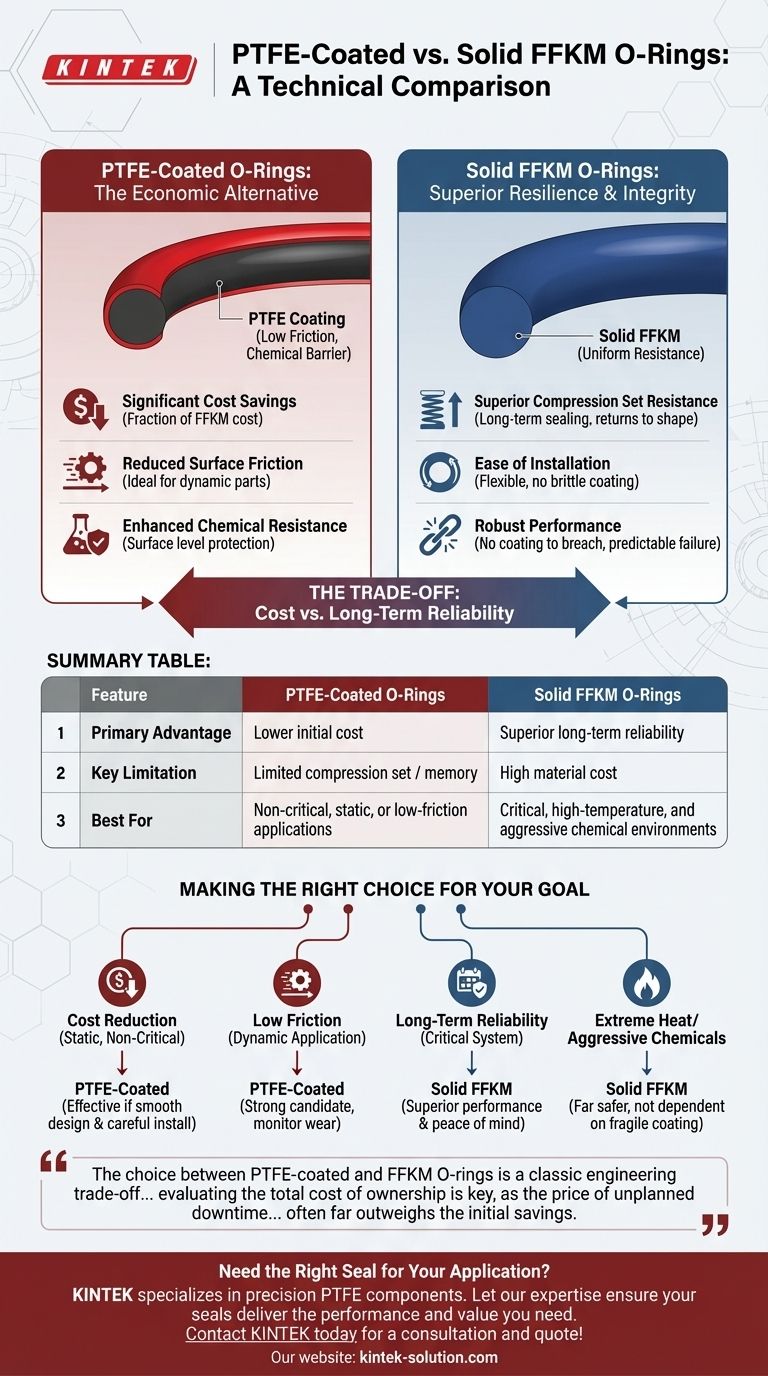

The choice between PTFE-coated and FFKM O-rings is a classic engineering trade-off: balancing the immediate cost savings and low friction of a coated seal against the superior resilience and long-term sealing integrity of a solid FFKM component.

The Core Advantage: A Matter of Economics and Surface Properties

The appeal of a PTFE-coated O-ring comes down to applying a high-performance surface onto a more economical base material. This creates specific benefits that can be ideal for certain applications.

Significant Cost Savings

A PTFE-coated O-ring typically uses a core of a standard elastomer, such as FKM (Viton®) or EPDM. The manufacturing cost of these base materials is a fraction of the cost of producing solid FFKM, which is one of the most expensive elastomers available.

Reduced Surface Friction

The PTFE (polytetrafluoroethylene) coating creates an extremely low-friction surface. This is a distinct advantage in dynamic applications where the O-ring slides against another part, as it reduces drag and can prevent stick-slip behavior.

Enhanced Chemical Resistance (Surface Level)

The coating acts as an inert chemical barrier, protecting the less-resistant elastomer core from aggressive media. This can effectively upgrade the performance of a standard O-ring in specific chemical environments.

Understanding the Trade-offs: Where FFKM Is Superior

While cost-effective, a coated O-ring is a composite part with inherent limitations. These trade-offs are precisely where the higher investment in a solid FFKM seal is justified.

The Problem of "Limited Memory" (Compression Set)

The references note PTFE-coated O-rings have "limited memory," a concept known as compression set. An effective seal must be able to return to its original shape after being compressed to maintain sealing force over time.

FFKM has excellent resistance to compression set, ensuring a reliable, long-term seal. The rigid PTFE coating, however, hinders the base elastomer's ability to rebound, making it more likely to take a permanent "set" and eventually fail.

Difficulty in Compression and Installation

The hard, relatively inflexible PTFE shell does not stretch or compress easily like a pure elastomer. This can make installation difficult and increases the risk of the coating cracking or flaking if it is stretched over a sharp edge or forced into a tight groove.

Failure Is Not Gradual

The performance of a coated O-ring depends entirely on the integrity of its thin coating. If the coating is scratched during installation or cracks under stress, the aggressive media can bypass it and attack the vulnerable elastomer core, leading to rapid seal failure.

In contrast, a solid FFKM O-ring has uniform chemical and thermal resistance throughout its entire structure. There is no surface layer to breach, making its performance far more robust and predictable in critical applications.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of the application's demands and the consequences of seal failure.

- If your primary focus is cost reduction in a static, non-critical application: A PTFE-coated O-ring can be an effective solution, provided the hardware design is smooth and installation is handled carefully.

- If your primary focus is low friction in a dynamic application: A PTFE-coated O-ring is a strong candidate, but you must weigh this against the risk of the coating wearing down over time.

- If your primary focus is long-term reliability in a critical system: The superior compression set resistance and monolithic structure of FFKM provide the performance and peace of mind that justify its higher cost.

- If your primary focus is extreme heat or aggressive chemicals: FFKM is the far safer choice, as its performance is not dependent on a fragile surface coating.

Ultimately, evaluating the total cost of ownership is key, as the price of unplanned downtime or system failure often far outweighs the initial savings on a seal.

Summary Table:

| Feature | PTFE-Coated O-Rings | Solid FFKM O-Rings |

|---|---|---|

| Primary Advantage | Lower initial cost | Superior long-term reliability |

| Key Limitation | Limited compression set / memory | High material cost |

| Best For | Non-critical, static, or low-friction applications | Critical, high-temperature, and aggressive chemical environments |

Need the Right Seal for Your Application?

Choosing between a cost-effective PTFE-coated seal and a high-performance solid FFKM O-ring is critical for your system's reliability and total cost of ownership. KINTEK specializes in manufacturing precision PTFE components, including custom seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

We can help you navigate this exact trade-off to find the optimal solution, offering custom fabrication from prototypes to high-volume orders. Let our expertise ensure your seals deliver the performance and value you need.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability