In practice, PTFE's extremely low coefficient of friction is a double-edged sword during machining. On one hand, it allows for clean cuts with minimal material adhesion to the cutting tool, reducing wear. On the other hand, this same slipperiness, combined with the material's inherent softness, makes it exceptionally difficult to hold securely and prone to distortion, demanding specific tools and techniques to maintain tight tolerances.

The core challenge of machining PTFE is that its most valuable property—slipperiness—is also its biggest liability in the workshop. Success depends on adapting your process to accommodate its low friction and softness, rather than trying to fight them with conventional methods.

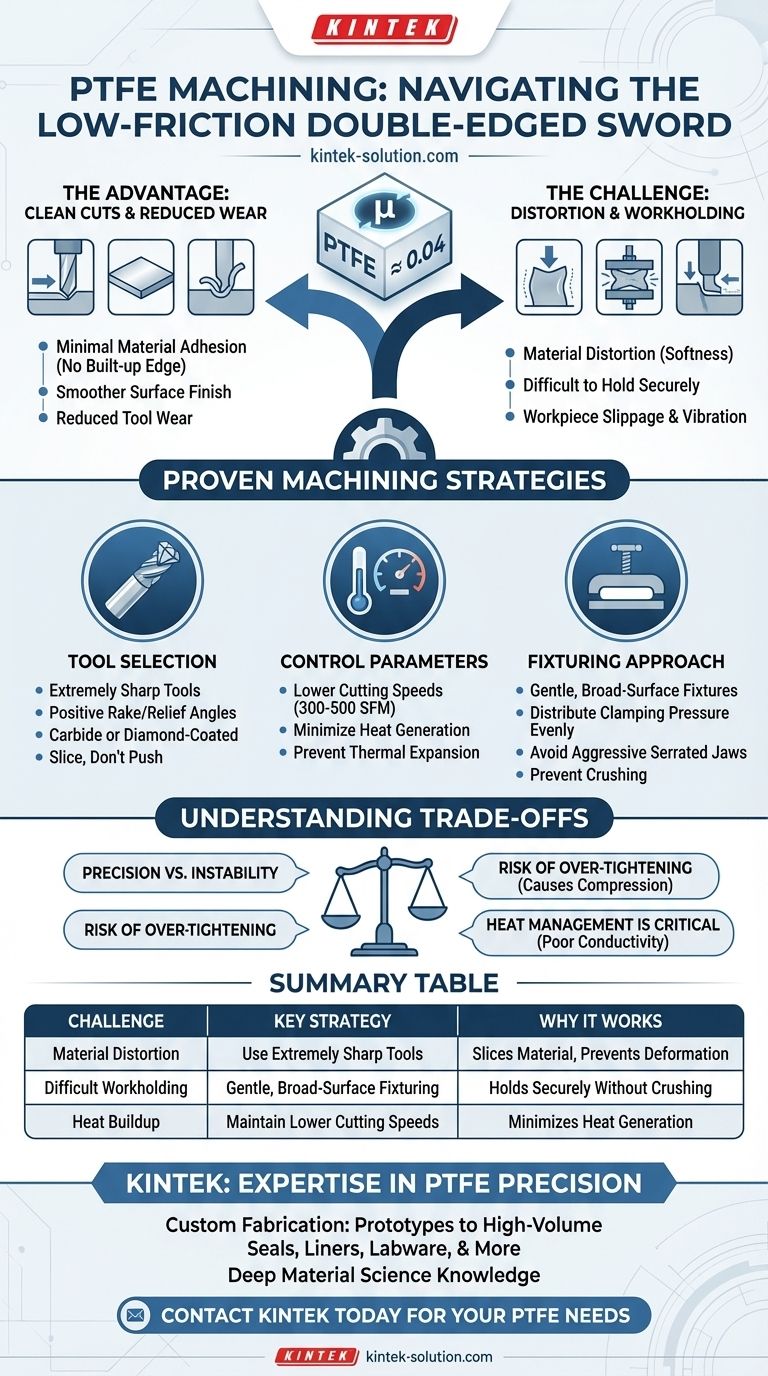

The Duality of Low Friction in Machining

PTFE's coefficient of friction, as low as 0.04, is less than that of any other solid engineering material. This single property creates both distinct advantages and significant challenges for the machinist.

The Advantage: Clean Cuts and Reduced Tool Wear

Because PTFE is so slick, material does not readily adhere to the cutting tool during machining. This phenomenon, known as "built-up edge," is a common problem with other plastics but is minimal with PTFE.

This results in a cleaner, smoother surface finish and significantly reduces wear on the cutting tool itself. The tool glides through the material rather than tearing it.

The Challenge: Material Distortion

The primary difficulty arises because PTFE is both soft and slippery. When a cutting tool applies pressure, the material is more likely to deform or push away rather than shear cleanly if the tool is not perfectly sharp.

This pliability makes holding tight dimensional tolerances a significant challenge, as the part can easily be compressed or distorted by cutting forces.

The Challenge: Workholding and Fixturing

PTFE's low friction makes it notoriously difficult to clamp securely. Applying the force needed to hold it in place often leads to another problem: deforming or crushing the soft material.

The workpiece has a natural tendency to slip or vibrate in the fixture, which can ruin dimensional accuracy and surface finish.

Proven Machining Strategies for PTFE

To overcome these challenges, you must adjust your approach, focusing on sharp tools, controlled parameters, and intelligent workholding.

Tool Selection is Non-Negotiable

You must use extremely sharp tools with a positive rake and significant relief angles. The goal is to slice the material, not push it.

Carbide or diamond-coated tools are highly recommended as they maintain their sharp edge far longer, ensuring consistent cutting action without deforming the part.

Control Your Cutting Parameters

High cutting speeds generate heat, which PTFE dissipates poorly, leading to thermal expansion and dimensional instability.

Using lower cutting speeds, typically in the range of 300–500 surface feet per minute (SFM), minimizes heat generation and prevents the material from "grabbing" the tool and distorting.

Rethink Your Fixturing Approach

Avoid aggressive clamping methods like serrated jaws. Instead, use fixtures with broad, smooth contact surfaces to distribute clamping pressure evenly.

This allows you to hold the part securely without applying the excessive localized force that would cause it to deform.

Understanding the Trade-offs

Machining PTFE effectively means balancing its unique properties against the demands of the final component.

Precision vs. Material Instability

The core conflict in machining PTFE is the quest for precision in a material that is inherently unstable under mechanical and thermal stress. Every decision must prioritize minimizing force and heat.

The Risk of Over-Tightening

The natural instinct to compensate for a slippery part is to tighten the fixture more. With PTFE, this is counterproductive. Over-tightening will compress the material, and the machined part will be out of tolerance once the pressure is released.

This is analogous to the challenges with PTFE-coated fasteners, where standard torque values must be adjusted to prevent over-stretching the bolt.

Heat Management is Critical

While low friction reduces heat generation compared to other materials, PTFE's poor thermal conductivity means that any heat that is generated stays localized. This can cause the material to expand significantly, ruining accuracy. A sharp tool and appropriate speed are your primary tools for heat management.

Key Adjustments for Successful PTFE Machining

Your specific approach should be guided by the primary goal for your finished component.

- If your primary focus is dimensional accuracy: Prioritize razor-sharp tooling and gentle, broad-surface workholding to prevent any compression or distortion.

- If your primary focus is surface finish: Concentrate on controlled, lower cutting speeds and light cutting depths to achieve a clean shearing action.

- If you are new to machining PTFE: Begin with conservative speeds and feeds, taking very light passes to understand how the material behaves before attempting more aggressive cuts.

By respecting PTFE's unique properties, you can transform a challenging material into a precisely finished component.

Summary Table:

| Challenge | Key Strategy | Why It Works |

|---|---|---|

| Material Distortion | Use extremely sharp tools (carbide/diamond) | Slices material instead of pushing it, preventing deformation |

| Difficult Workholding | Employ gentle, broad-surface fixturing | Holds part securely without crushing or compressing the soft PTFE |

| Heat Buildup | Maintain lower cutting speeds (300-500 SFM) | Minimizes heat generation that PTFE dissipates poorly, preventing expansion |

Struggling to Machine PTFE to Precise Tolerances?

PTFE's unique properties require specialized expertise to machine successfully. At KINTEK, we manufacture precision PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. Our deep understanding of material science allows us to overcome the challenges of low friction and softness, ensuring your parts meet the tightest dimensional and surface finish requirements.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your PTFE machining needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is a PTFE lined dual plate check valve? A Guide to Corrosion-Resistant Backflow Prevention

- What alternatives to PTFE are available for sealing applications? Find the Right Material for Your Sealing Needs

- What are the general benefits of using PTFE for sealing applications? Master Chemical & Thermal Resistance

- What is the difference between Teflon valves and PTFE lined valves? Choose the Right Valve for Your System

- What types of PTFE processing machines are commonly used? From Extrusion to Precision Machining

- What are the limitations of PTFE gaskets in high-pressure applications? Overcoming Cold Flow & Creep Issues

- What are some potential drawbacks of using Teflon sheets? Heat Transfer, Slippage & Safety Risks

- What makes expanded PTFE gaskets more suitable for sealing applications than pure PTFE gaskets? Solve Cold Flow for Reliable Seals