To successfully machine Teflon (PTFE), a range of processes can be employed, but all require specific adaptations to the material's unique properties. The most common methods are CNC milling and turning, which offer high precision, followed by specialized techniques like drilling with specific tool geometries, grinding, and waterjet or die cutting for different stock forms. The key is using exceptionally sharp tools, managing heat buildup, and accounting for the material's tendency to deform under pressure.

While standard equipment like mills and lathes are used, machining PTFE is fundamentally a practice in material management. Success depends less on the machine itself and more on controlling the material's inherent softness, high thermal expansion, and tendency to "creep," which standard metal-focused techniques fail to address.

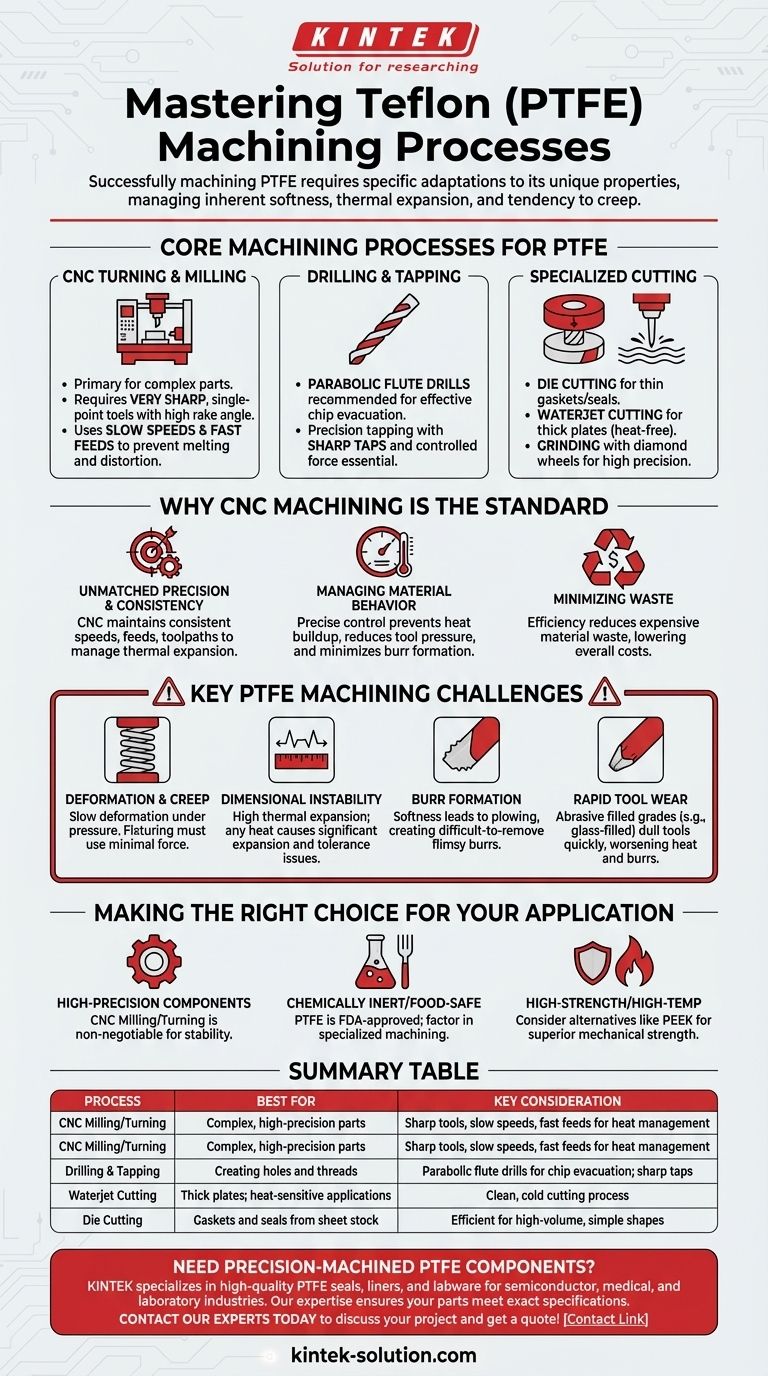

Core Machining Processes for PTFE

Polytetrafluoroethylene (PTFE), or Teflon, is exceptionally soft and has a high coefficient of thermal expansion. This dictates the choice and application of every machining process.

CNC Turning & Milling

These are the primary methods for creating complex PTFE parts. Success relies on very specific parameters to avoid melting, deformation, or poor surface finish.

The strategy involves using very sharp, single-point cutting tools with a high rake angle. Machinists typically use slow speeds combined with fast feeds to create chips that carry heat away from the workpiece efficiently, preventing dimensional distortion.

Drilling & Tapping

Drilling PTFE requires careful chip evacuation to prevent friction and heat. Parabolic flute drills are often recommended as their shape helps clear the soft, stringy swarf more effectively than standard drills.

When creating threads, precision tapping is essential. Because the material can easily deform or strip, sharp taps and controlled force are necessary to produce clean, functional threads.

Specialized Cutting Methods

For specific forms of PTFE stock, other methods are more suitable. Die cutting is an efficient process for producing gaskets or seals from thin sheets.

For thicker plates where heat from traditional machining could be a problem, waterjet cutting offers a clean, heat-free alternative. For achieving very high-precision surfaces, grinding with diamond wheels can be used, though it is less common.

Why CNC Machining is the Standard

While manual machining is possible for simple prototypes, CNC is the preferred method for any production-level PTFE components. This is a direct response to the material's challenging properties.

Unmatched Precision & Consistency

PTFE's high thermal expansion means even small temperature changes during machining can throw a part out of tolerance. A CNC machine's ability to maintain consistent speeds, feeds, and toolpaths provides the control needed to manage these variables and produce repeatable parts.

Managing Material Behavior

The programmability of CNC allows for the precise, slow-speed, fast-feed strategy that PTFE requires. This controlled environment is crucial for preventing heat buildup, reducing tool pressure, and minimizing burr formation at the edges of cuts.

Minimizing Waste

PTFE can be a relatively expensive material. The efficiency and optimization offered by CNC machining reduce material waste compared to manual methods, leading to lower overall part costs.

Understanding the Trade-offs: Key PTFE Machining Challenges

Choosing to machine PTFE means accepting and planning for its inherent limitations. Ignoring these factors is the primary cause of failed parts.

Deformation and Creep

PTFE has low mechanical strength and a tendency for "creep" or "cold flow." This means it will slowly deform over time when under continuous pressure. Fixturing and clamping must be done with minimal force to avoid distorting the part before the first cut is even made.

Dimensional Instability

The material's thermal expansion is many times greater than that of metals. Any heat generated by dull tools or improper feeds will cause the material to expand significantly, making it impossible to hold tight tolerances.

Burr Formation

The softness of PTFE means that instead of creating a clean chip, tools can sometimes push or "plow" the material. This results in flimsy burrs along the machined edges that are difficult to remove without damaging the part's surface.

Rapid Tool Wear

While soft, some grades of filled PTFE (like glass-filled) are highly abrasive. This leads to rapid tool wear, which dulls cutting edges and immediately exacerbates issues with heat generation and burr formation.

Making the Right Choice for Your Application

Selecting the right process and material depends entirely on the component's end-use requirements.

- If your primary focus is high-precision components: CNC milling and turning are non-negotiable for their ability to control the variables that affect PTFE's dimensional stability.

- If your primary focus is chemically inert or food-safe parts: PTFE is an excellent choice, as it is FDA-approved, but you must factor in the specialized machining requirements to maintain part integrity.

- If your primary focus is high-strength or high-temperature stability: Consider an alternative like PEEK, which offers superior mechanical strength and thermal resistance while still providing excellent chemical resistance.

By understanding and respecting the unique properties of PTFE, you can transform its machining challenges into predictable and successful outcomes.

Summary Table:

| Process | Best For | Key Consideration |

|---|---|---|

| CNC Milling/Turning | Complex, high-precision parts | Sharp tools, slow speeds, fast feeds to manage heat |

| Drilling & Tapping | Creating holes and threads | Parabolic flute drills for chip evacuation; sharp taps |

| Waterjet Cutting | Thick plates; heat-sensitive applications | Clean, cold cutting process |

| Die Cutting | Gaskets and seals from sheet stock | Efficient for high-volume, simple shapes |

Need precision-machined PTFE components? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts meet exact specifications by mastering the unique challenges of PTFE machining. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE gaskets suitable for aerospace applications? Unmatched Reliability in Extreme Conditions

- Why are ePTFE gaskets considered hygienic? Ensure Product Purity with a Reliable Seal

- What challenges arise during the manufacturing of skived PTFE sheets? Achieving Consistent Quality and Performance

- How are PTFE bushes designed and manufactured? A Guide to Custom Engineered Components

- What are the main features of PTFE bushings? Unlock Superior Performance in Harsh Environments

- What role do ceramic fillers play in PTFE laminates? Enhance Signal Integrity & Thermal Performance

- What is the function of a teflon check valve in control systems? Prevent Backflow in Corrosive & High-Temp Processes

- Why are PTFE washers resistant to water and moisture? Unlocking the Power of Hydrophobic Sealing