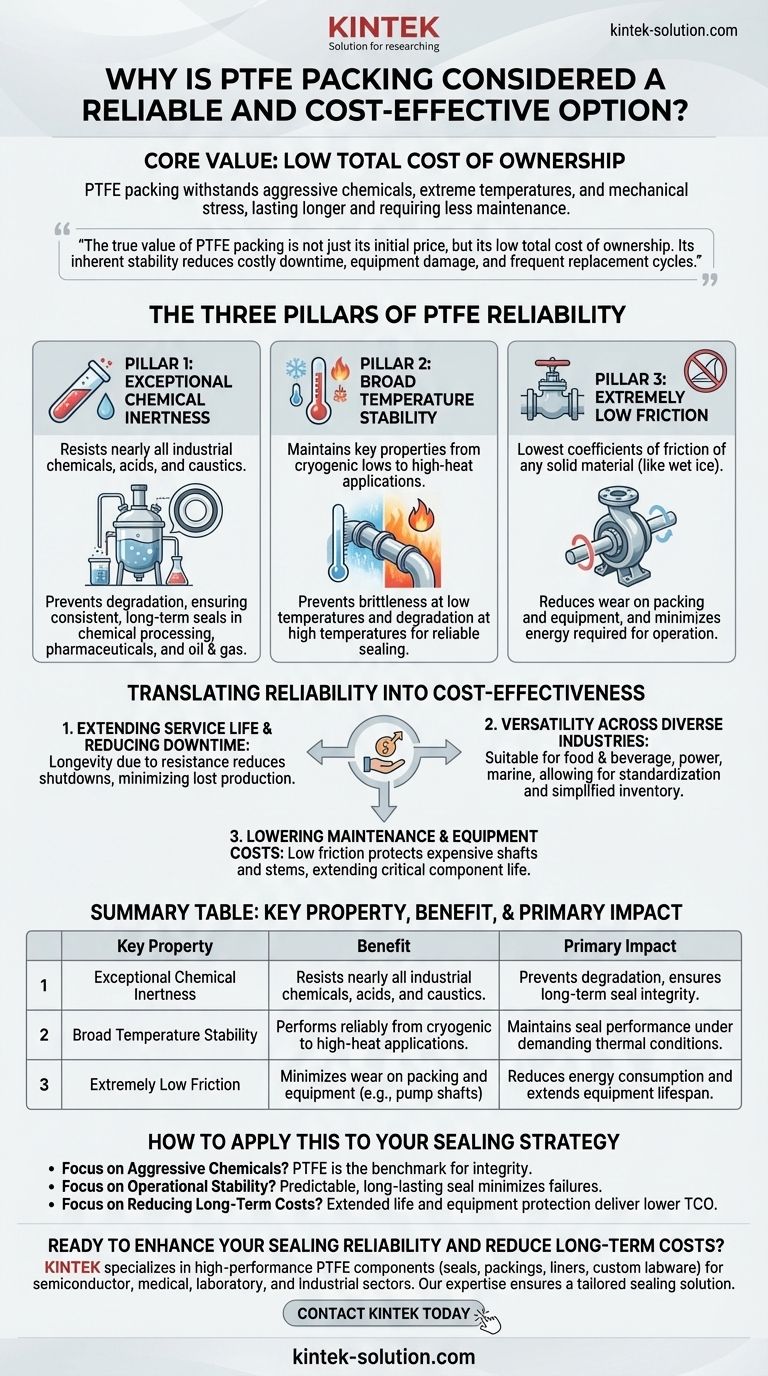

At its core, PTFE packing is considered a reliable and cost-effective sealing solution because its fundamental material properties directly counter the most common causes of industrial seal failure. Its ability to withstand aggressive chemicals, extreme temperatures, and mechanical stress means it lasts longer and requires less maintenance, providing significant value over its operational lifespan.

The true value of PTFE packing is not just its initial price, but its low total cost of ownership. Its inherent chemical and thermal stability reduces costly downtime, equipment damage, and frequent replacement cycles common with lesser materials.

The Three Pillars of PTFE Reliability

To understand why PTFE is a default choice for so many demanding applications, we must look at its three core characteristics. These properties work in concert to create a highly durable and stable seal.

Pillar 1: Exceptional Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and caustics. This chemical inertness is critical for preventing material degradation.

Where other materials would corrode or swell, PTFE maintains its structural integrity. This ensures a consistent, long-term seal in environments like chemical processing, pharmaceuticals, and oil and gas.

Pillar 2: Broad Temperature Stability

Industrial processes often involve significant temperature fluctuations, from cryogenic lows to high-heat applications. PTFE packing maintains its key properties across this wide spectrum.

This thermal stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures, ensuring a reliable seal under demanding operational conditions.

Pillar 3: Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This non-adhesive surface has two primary benefits.

First, it reduces the wear and tear on both the packing and the equipment, such as pump shafts or valve stems. Second, it minimizes the energy required to operate the equipment, contributing to greater efficiency.

Translating Reliability into Cost-Effectiveness

The technical reliability of PTFE directly translates into tangible economic benefits. Its performance justifies its use by lowering operational costs over time.

Extending Service Life and Reducing Downtime

The primary driver of cost-effectiveness is longevity. Because PTFE resists chemical attack and thermal degradation, it simply lasts longer in service.

This durability means fewer shutdowns for seal replacement, directly reducing maintenance labor costs and, more importantly, minimizing lost production from unplanned downtime.

Versatility Across Diverse Industries

PTFE's robust profile makes it suitable for an exceptionally broad range of uses. It is a trusted material in everything from food and beverage production to power generation and marine applications.

This versatility allows for standardization, simplifying inventory and purchasing for facilities with diverse sealing requirements.

Lowering Maintenance and Equipment Costs

The low-friction nature of PTFE not only saves energy but also protects expensive equipment. It reduces scoring and wear on shafts and stems.

This protection extends the life of critical components, preventing costly repairs or premature equipment replacement.

How to Apply This to Your Sealing Strategy

Your specific operational goal will determine how you leverage PTFE's advantages.

- If your primary focus is handling aggressive chemicals: PTFE is the benchmark choice for ensuring seal integrity and preventing corrosive leaks.

- If your primary focus is operational stability: The material's thermal range and durability provide a predictable, long-lasting seal that minimizes unexpected failures.

- If your primary focus is reducing long-term costs: PTFE's extended service life and ability to protect equipment deliver a lower total cost of ownership compared to conventional packing materials.

By understanding its core properties, you can confidently specify PTFE packing as a strategic component for enhancing both reliability and financial performance.

Summary Table:

| Key Property | Benefit | Primary Impact |

|---|---|---|

| Exceptional Chemical Inertness | Resists nearly all industrial chemicals, acids, and caustics. | Prevents degradation, ensures long-term seal integrity. |

| Broad Temperature Stability | Performs reliably from cryogenic to high-heat applications. | Maintains seal performance under demanding thermal conditions. |

| Extremely Low Friction | Minimizes wear on packing and equipment (e.g., pump shafts). | Reduces energy consumption and extends equipment lifespan. |

Ready to enhance your sealing reliability and reduce long-term costs?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, packings, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution tailored to your specific chemical, thermal, and operational demands.

Contact KINTEK today to discuss how our PTFE solutions can lower your total cost of ownership and maximize uptime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry