At their core, PTFE bellows are used wherever systems require protection from chemical, thermal, or mechanical stress in demanding environments. They serve critical functions in industries like chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing. Specific applications include isolating sensitive components in pumps and valves, compensating for thermal expansion in pipe systems, and shielding sterile areas from contamination.

The true value of a PTFE bellow isn't just its flexibility, but its unique ability to combine that flexibility with near-universal chemical inertness and high-temperature stability. This makes it the default solution for protecting critical, dynamic systems in the most aggressive industrial environments.

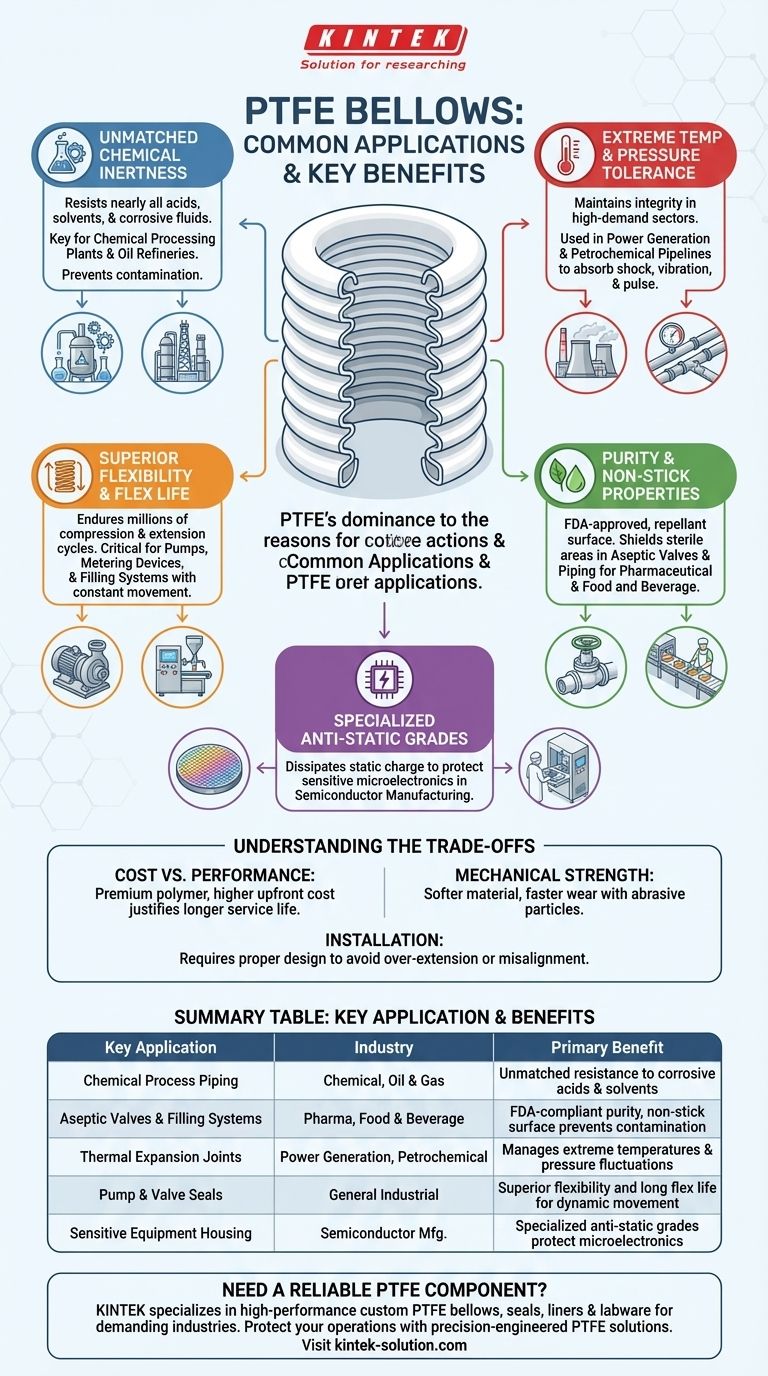

Why PTFE Dominates Demanding Bellows Applications

The widespread use of PTFE (polytetrafluoroethylene) is not accidental. It stems from a combination of properties that make it uniquely suited for creating a flexible barrier between a harsh process environment and a sensitive mechanical component.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all industrial chemicals, acids, and solvents. This makes it an essential material in chemical processing plants and oil refineries, where it is used to handle corrosive fluids without degrading.

This chemical stability ensures the bellow itself does not become a point of failure or a source of contamination in the system.

Extreme Temperature and Pressure Tolerance

PTFE bellows maintain their integrity and performance across a wide range of temperatures and pressures. This allows them to be used in high-demand sectors like power generation and petrochemical pipelines.

They reliably absorb shock and vibration, acting as pulse dampeners or balancing elements between engineering parts under significant thermal or mechanical stress.

Superior Flexibility and Flex Life

A bellow's primary function is to move. PTFE offers an excellent flex life, meaning it can endure millions of cycles of compression and extension without cracking or failing.

This durability is critical in dynamic applications like pumps, metering devices, and filling systems, where constant movement is part of normal operation.

Purity and Non-Stick Properties

In the pharmaceutical and food and beverage industries, preventing contamination is paramount. PTFE is FDA-approved and has a non-stick, repellant surface that resists buildup and is easy to clean.

This property is leveraged to shield sterile areas in aseptic valves and prevent cross-contamination in intricate piping networks, ensuring product purity.

Specialized Anti-Static Grades

Standard PTFE is an insulator, which can allow static electricity to build up. In sensitive applications like semiconductor manufacturing, this static discharge can damage or destroy microelectronics.

Specialized anti-static PTFE grades are available that safely dissipate this charge, making them the material of choice for protecting sensitive high-tech manufacturing systems.

Understanding the Trade-offs

While PTFE is a superior material for many applications, it's essential to understand its relative trade-offs to make an informed engineering decision.

Cost vs. Performance

PTFE is a premium polymer, and bellows made from it are typically more expensive than those made from elastomers like EPDM or silicone. The higher upfront cost is justified by its vastly superior chemical and thermal resistance, which leads to longer service life and lower maintenance in aggressive environments.

Mechanical Strength and Abrasion

While highly durable in terms of flex life, PTFE is a relatively soft material. In applications with significant abrasive particles, it may wear faster than a metal bellow. However, for most fluid and gas applications, this is not a limiting factor.

Design and Installation Sensitivity

The performance of a PTFE bellow is highly dependent on proper system design and installation. Factors like over-extension, excessive torsion, or misalignment can prematurely shorten its lifespan. Proper engineering and following manufacturer guidelines are critical to achieving its full potential.

Making the Right Choice for Your System

Selecting the correct bellow material is a matter of matching its properties to the primary challenge of your application.

- If your primary focus is purity and preventing contamination: Choose FDA-compliant PTFE bellows for their non-stick surface and chemical inertness, ideal for pharmaceutical, food, or semiconductor applications.

- If your primary focus is handling aggressive chemicals and high temperatures: PTFE's near-universal chemical resistance makes it the safest choice for chemical processing, petrochemicals, and power generation.

- If your primary focus is managing static discharge in a clean environment: Specify an anti-static PTFE bellow to protect sensitive electronics in semiconductor or advanced manufacturing.

- If your primary focus is accommodating thermal expansion and vibration: A PTFE bellow provides a flexible, low-maintenance solution to protect piping and equipment from mechanical stress.

Ultimately, choosing a PTFE bellow is an investment in system reliability and long-term operational integrity.

Summary Table:

| Key Application | Industry | Primary Benefit of PTFE Bellow |

|---|---|---|

| Chemical Process Piping | Chemical Processing, Oil & Gas | Unmatched resistance to corrosive acids and solvents |

| Aseptic Valves & Filling Systems | Pharmaceutical, Food & Beverage | FDA-compliant purity, non-stick surface prevents contamination |

| Thermal Expansion Joints | Power Generation, Petrochemical | Manages extreme temperatures and pressure fluctuations |

| Pump & Valve Seals | General Industrial | Superior flexibility and long flex life for dynamic movement |

| Sensitive Equipment Housing | Semiconductor Manufacturing | Specialized anti-static grades protect microelectronics |

Need a reliable PTFE component for your critical application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom bellows, seals, liners, and labware. We serve demanding industries like semiconductor, medical, laboratory, and industrial processing. Our expertise ensures precision production and custom fabrication—from initial prototypes to high-volume orders—delivering the chemical resistance, temperature stability, and purity your system requires.

Contact KINTEK today to discuss your specific needs and protect your operations with precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key features of a Lined Plug Valve? Robust Corrosion Resistance & Maximum Flow

- What maintenance practices ensure optimal PTFE butterfly valve performance? Maximize Lifespan & Reliability

- What are the key properties of PTFE that make it suitable for structural bearings? Unlock Superior Load Support & Movement

- What is a floating ball valve and how does it seal line pressure? A Guide to Pressure-Actuated Sealing

- Why are PTFE gaskets used in the pharmaceutical and food industries? Ensure Purity and Safety in Sanitary Applications

- What are the benefits of carbon fiber filled PTFE? Boost Strength, Wear & Heat Dissipation

- What are the key characteristics of PTFE O-rings? Engineered for Extreme Chemical and Thermal Resistance

- What role does PTFE play in the printing and packaging industry? Enhancing Efficiency and Quality