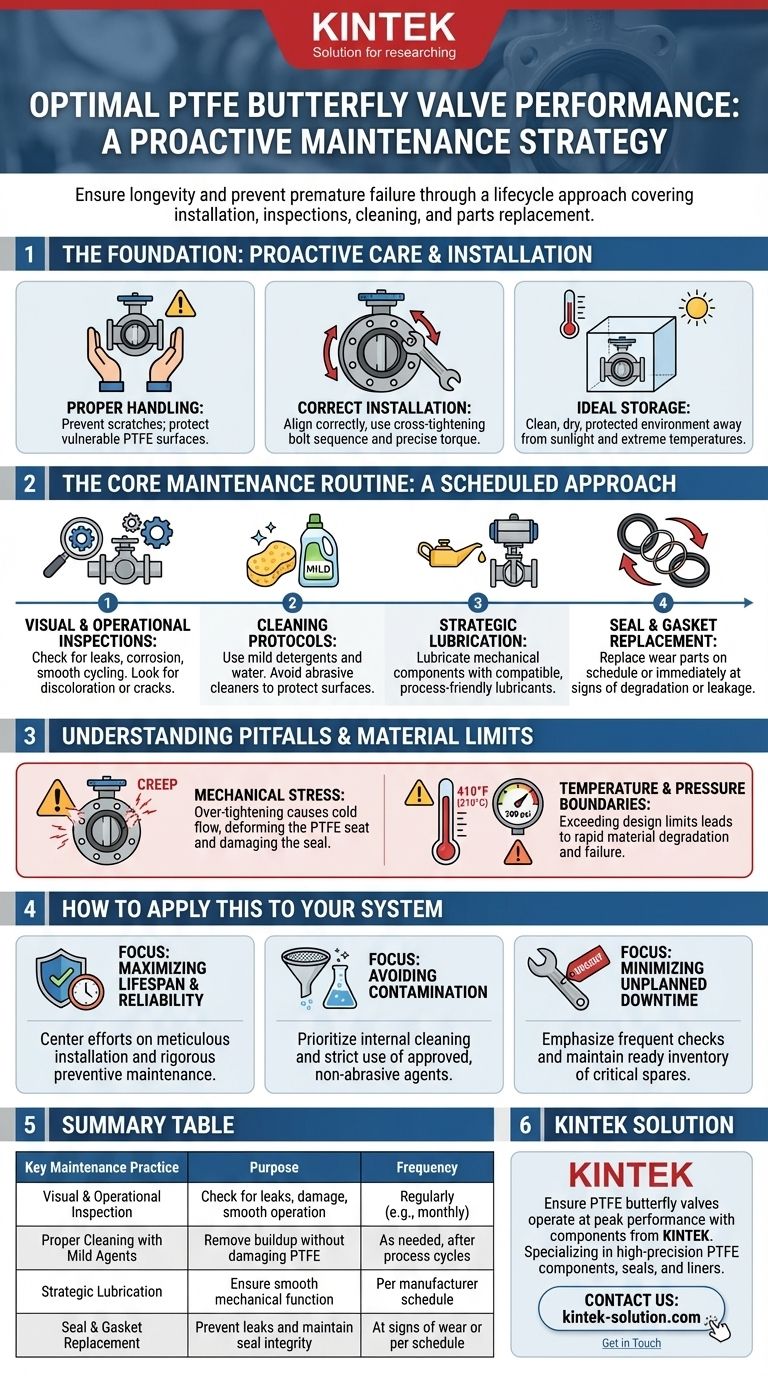

To ensure optimal performance and longevity, a PTFE butterfly valve requires a maintenance strategy built on four key practices: regular visual and operational inspections, proper cleaning using mild agents, strategic lubrication of mechanical components, and the timely replacement of wear parts like seals and gaskets. This proactive approach prevents premature failure and guarantees the valve operates as designed.

The most effective maintenance for a PTFE valve is not a reactive checklist, but a comprehensive lifecycle strategy. It begins with correct installation and handling and is sustained by a deep understanding of PTFE's material limitations regarding temperature, pressure, and mechanical stress.

The Foundation: Proactive Care and Installation

Effective maintenance begins long before the first scheduled inspection. The initial handling and installation of the valve set the stage for its entire operational life.

The Importance of Proper Handling

Even before installation, PTFE surfaces are vulnerable. Careless handling can cause scratches or gouges on the valve's seating surfaces.

These seemingly minor imperfections can become leak paths or points of accelerated wear once the valve is in service.

Correct Installation Procedures

Proper installation is a critical, non-negotiable step. Misalignment of the valve between pipe flanges creates uneven pressure on the PTFE seat, leading to premature failure.

Always use a cross-tightening bolt sequence with the correct torque specifications to ensure the valve is seated evenly and without excessive mechanical stress.

Ideal Storage Conditions

If a valve is not being installed immediately, store it in a clean, dry environment. Protecting it from direct sunlight and extreme temperatures prevents the degradation of the PTFE material before it ever enters service.

The Core Maintenance Routine: A Scheduled Approach

Once a valve is operational, a consistent and scheduled routine is essential for identifying and addressing issues before they cause downtime.

Regular Visual & Operational Inspections

Visually inspect the valve's exterior for any signs of leaks, corrosion, or damage. Operationally, cycle the valve to ensure it opens and closes smoothly without excessive force.

Look for any discoloration or cracks in the visible PTFE components, as this can indicate chemical attack or heat degradation.

Cleaning Protocols for PTFE

When cleaning is necessary, use only mild detergents and water. Avoid abrasive cleaners or harsh chemicals, as these can damage the sensitive PTFE surfaces.

The goal is to remove process buildup without compromising the integrity of the valve's liner or seat.

Strategic Lubrication

Lubrication should be applied to the valve's mechanical components, such as the stem and actuator. This ensures smooth mechanical operation.

It is crucial to use a lubricant that is compatible with both the valve materials and the process media.

Seal and Gasket Replacement

Seals and gaskets are wear components with a finite lifespan. They should be inspected during every maintenance interval for signs of degradation, brittleness, or leakage.

Replace them according to the manufacturer’s schedule or immediately if any signs of wear are observed.

Understanding the Pitfalls and Material Limits

PTFE is a high-performance material, but it is not indestructible. Understanding its limitations is key to preventing common failure modes.

The Enemy of PTFE: Mechanical Stress

The most common cause of premature failure in PTFE-lined valves is excessive mechanical stress. This is often caused by over-tightening flange bolts during installation.

This "creep" or cold flow deforms the PTFE seat, permanently damaging its ability to create a reliable seal.

Temperature and Pressure Boundaries

PTFE has strict operational limits. Most PTFE butterfly valves are designed for service below 410°F (210°C) and 300 psi.

Operating the valve outside these parameters will cause rapid degradation of the material, leading to seal failure and potential safety hazards.

How to Apply This to Your System

Your maintenance strategy should align directly with your system's operational priorities. A tailored approach ensures you invest resources where they will have the greatest impact.

- If your primary focus is maximizing lifespan and reliability: Center your efforts on a meticulous installation process and a rigorously followed preventive maintenance schedule for inspections and lubrication.

- If your primary focus is avoiding process contamination: Prioritize internal cleaning protocols and strict adherence to using only approved, non-abrasive cleaning agents.

- If your primary focus is minimizing unplanned downtime: Emphasize frequent operational checks to catch issues early and maintain a ready inventory of critical spares like seals and gaskets.

Ultimately, treating valve maintenance as a continuous strategy rather than an occasional task is the key to achieving system reliability.

Summary Table:

| Key Maintenance Practice | Purpose | Frequency |

|---|---|---|

| Visual & Operational Inspection | Check for leaks, damage, smooth operation | Regularly (e.g., monthly) |

| Proper Cleaning with Mild Agents | Remove buildup without damaging PTFE | As needed, after process cycles |

| Strategic Lubrication | Ensure smooth mechanical function | Per manufacturer schedule |

| Seal & Gasket Replacement | Prevent leaks and maintain seal integrity | At signs of wear or per schedule |

Ensure your PTFE butterfly valves operate at peak performance with components from KINTEK.

We specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact parts you need for reliable, long-lasting performance.

Contact us today to discuss your PTFE component requirements and how we can help optimize your valve maintenance strategy: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts