In the printing and packaging industry, Polytetrafluoroethylene (PTFE) is primarily used as a high-performance coating for critical components like transport belts and sealing sheets. Its function is to ensure that processes involving heat, ink, and adhesives run smoothly and efficiently without interruption from sticking or contamination.

The value of PTFE in printing and packaging stems from its unique combination of three critical properties: a non-stick surface, high heat resistance, and low friction. This trifecta solves the core challenges of adhesion, temperature, and material flow in high-speed production environments.

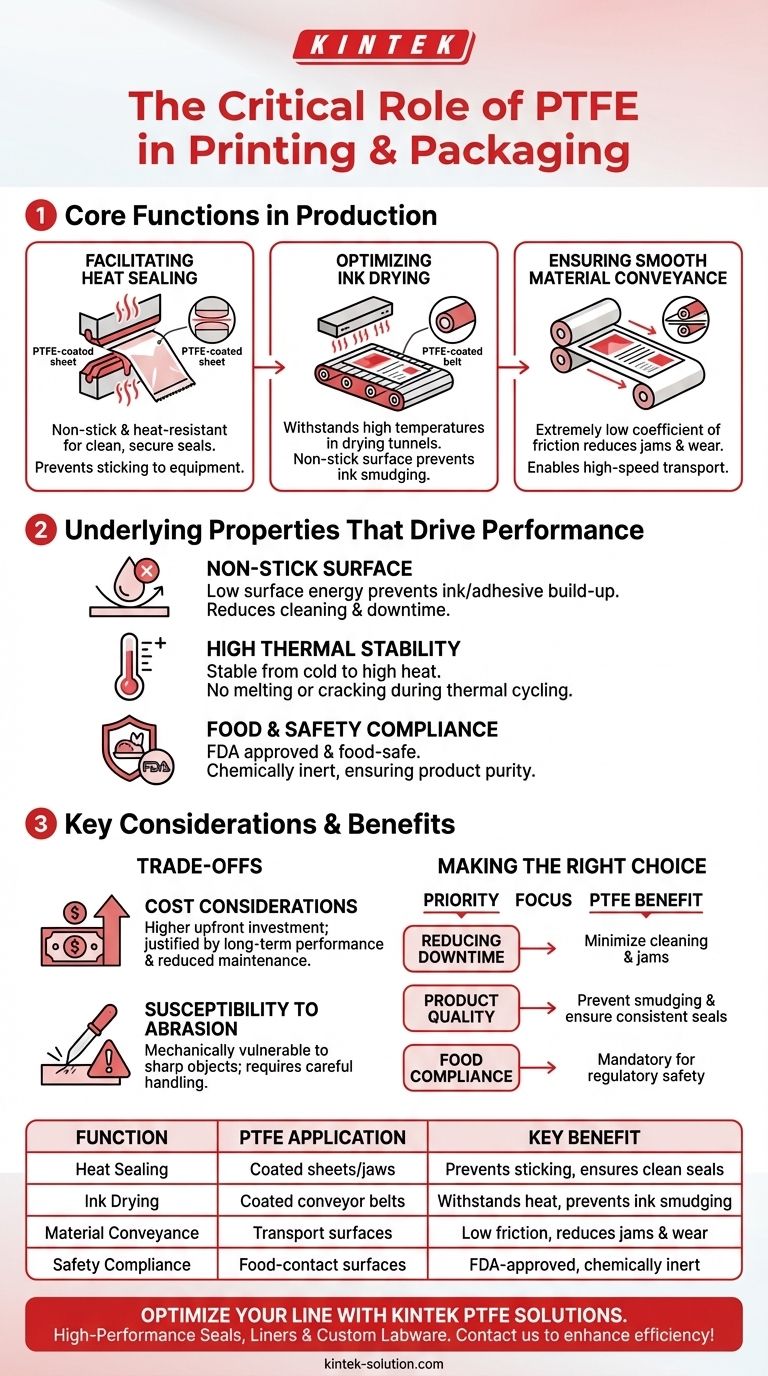

The Core Functions of PTFE in Production Lines

PTFE-coated components are not just parts; they are solutions to specific, high-friction points in the manufacturing process. Their application is targeted where heat, adhesion, and movement intersect.

Facilitating Heat Sealing

In packaging, heat is used to seal plastics and films together to create a secure closure.

PTFE-coated sheets or jaws are used as the contact surface. The material’s excellent heat resistance prevents it from degrading, while its non-stick nature ensures the molten plastic of the package seals to itself, not to the equipment.

Optimizing Ink Drying

After printing, materials must pass through drying tunnels or be exposed to heat sources to cure the ink.

PTFE-coated conveyor belts carry these materials through the drying process. The belts can withstand the high temperatures, and their non-stick surface prevents wet ink from smudging or transferring, which is critical for maintaining print quality.

Ensuring Smooth Material Conveyance

The movement of printed papers, labels, or formed packages along a production line must be seamless.

The extremely low coefficient of friction of PTFE means materials slide over its surface with minimal resistance. This prevents jams, reduces wear on machinery, and allows for higher transport speeds without damaging the product.

The Underlying Properties That Drive Performance

To understand why PTFE is the material of choice, you must understand the specific physical properties that make it so effective for these applications.

The Non-Stick Surface

Also known as low surface energy, this is PTFE’s most famous characteristic. It prevents inks, glues, and other adhesives from adhering to machinery surfaces.

This single property dramatically reduces the need for cleaning, minimizes production downtime, and prevents product defects caused by material build-up.

High Thermal Stability

PTFE remains stable across a wide range of temperatures, making it ideal for processes that cycle between hot and cold.

It can easily handle the temperatures required for both heat sealing and ink curing without melting, cracking, or releasing harmful fumes, ensuring process reliability and equipment longevity.

Food and Safety Compliance

For a large segment of the packaging industry, material safety is non-negotiable.

PTFE is FDA approved and food-safe, making it an essential choice for any equipment that comes into contact with food packaging. Its chemical inertness also means it won't react with or contaminate the products it touches.

Understanding the Trade-offs

While highly effective, PTFE is not without its practical considerations. Acknowledging them is key to making an informed decision.

Cost Considerations

PTFE coatings represent a higher upfront investment compared to simpler materials like silicone or untreated fabrics.

This cost is typically justified by superior performance, longer component life, and a significant reduction in maintenance-related downtime over the long term.

Susceptibility to Abrasion

While thermally and chemically robust, PTFE coatings can be mechanically damaged by sharp objects or highly abrasive materials.

Care must be taken in handling and maintenance to avoid scratching the surface, which could compromise its non-stick performance.

Making the Right Choice for Your Goal

Understanding these principles allows you to select and manage materials based on your specific operational priorities.

- If your primary focus is reducing downtime: The non-stick and low-friction properties of PTFE are your greatest assets, as they directly minimize cleaning needs and material jams.

- If your primary focus is product quality: PTFE's smooth, non-stick surface is critical for preventing ink smudging during drying and ensuring clean, consistent heat seals.

- If your primary focus is food packaging compliance: The FDA-approved, food-safe status of PTFE makes it a mandatory consideration for ensuring regulatory adherence and consumer safety.

Ultimately, leveraging PTFE in your operations is an investment in process stability, product integrity, and overall efficiency.

Summary Table:

| Function | PTFE Application | Key Benefit |

|---|---|---|

| Heat Sealing | Coated sheets/jaws | Prevents sticking, ensures clean seals |

| Ink Drying | Coated conveyor belts | Withstands heat, prevents ink smudging |

| Material Conveyance | Transport surfaces | Low friction, reduces jams and wear |

| Safety Compliance | Food-contact surfaces | FDA-approved, chemically inert |

Optimize your printing and packaging line with precision-engineered PTFE components from KINTEK.

Our PTFE seals, liners, and custom labware are designed to withstand high temperatures, resist chemicals, and provide unmatched non-stick performance—ensuring smoother operations, reduced downtime, and superior product quality. Whether you need prototypes or high-volume orders for semiconductor, medical, or industrial applications, KINTEK delivers reliable solutions tailored to your needs.

Contact us today to discuss how our PTFE expertise can enhance your production efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability