In the pharmaceutical and food industries, PTFE gaskets are the default choice for sanitary applications because they are chemically inert, non-toxic, and do not contaminate the products they seal. Their unique properties ensure that the final product—whether a medication or a food item—remains pure, safe, and free from any interaction with the sealing material itself, satisfying strict regulatory standards.

The core challenge in sanitary processing is not just preventing leaks, but ensuring the seal itself is an invisible, non-interactive barrier. PTFE is valued because it comes closer than most materials to achieving this ideal, protecting product integrity above all else.

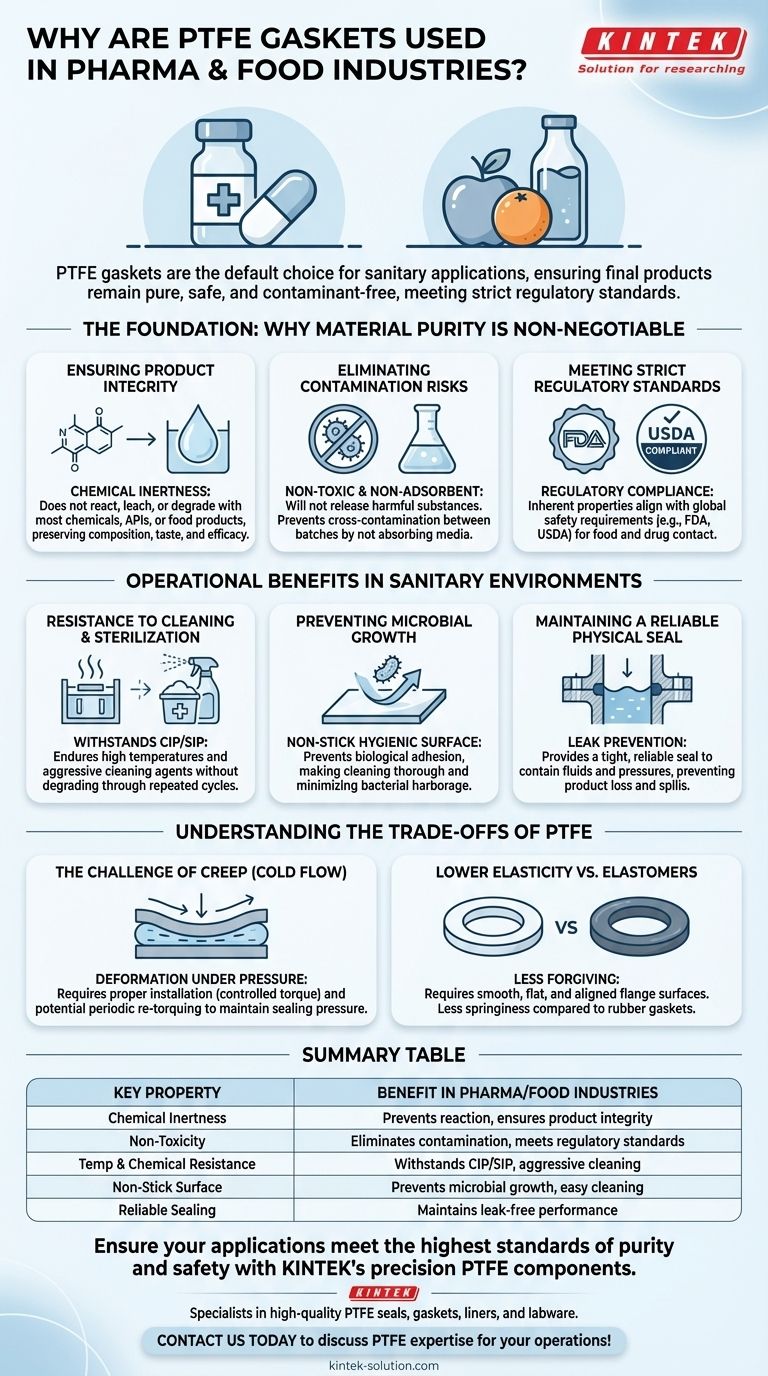

The Foundation: Why Material Purity is Non-Negotiable

In regulated environments, every component that touches the product is a potential source of contamination. Gasket material selection is therefore a critical control point for ensuring safety and quality.

Ensuring Product Integrity

A key reason for using PTFE is its chemical inertness. It does not react with, leach into, or degrade when exposed to the vast majority of chemicals, active pharmaceutical ingredients (APIs), or food products.

This ensures the product's chemical composition, taste, and efficacy remain completely unchanged from start to finish.

Eliminating Contamination Risks

PTFE is fundamentally non-toxic and non-adsorbent. It will not release harmful substances into the process stream, which is a baseline requirement for food and drug safety.

Furthermore, because it doesn't absorb the media it's sealing, the risk of cross-contamination between different product batches is significantly minimized.

Meeting Strict Regulatory Standards

These inherent properties allow PTFE formulations to meet the stringent requirements of global regulatory bodies.

Materials used in these industries must often be compliant with standards set by the FDA (U.S. Food and Drug Administration) or USDA (U.S. Department of Agriculture). PTFE's track record of safety and purity makes it a reliable, pre-approved choice.

Operational Benefits in Sanitary Environments

Beyond its core purity, PTFE delivers practical advantages that are essential for the daily operations of a processing plant.

Resistance to Cleaning and Sterilization

Pharmaceutical and food facilities rely on aggressive Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures.

PTFE withstands both high temperatures and a wide range of potent cleaning agents and sterilizing chemicals. This ensures the gasket maintains its integrity through repeated cleaning cycles without degrading.

Preventing Microbial Growth

The surface of PTFE is extremely smooth and non-stick. This hygienic property prevents biological material from adhering to the gasket surface.

A surface that resists buildup is easier to clean thoroughly and is less likely to harbor bacteria, which is critical for maintaining sanitary conditions.

Maintaining a Reliable Physical Seal

While purity is paramount, a gasket's primary function is still to prevent leaks. PTFE provides a tight, reliable seal that contains fluids and pressures within the processing equipment.

This prevents loss of valuable product and protects the external environment from potential spills.

Understanding the Trade-offs of PTFE

No material is perfect. While PTFE is an exceptional choice for sanitary applications, a technical advisor must also acknowledge its mechanical limitations to ensure its proper use.

The Challenge of Creep (Cold Flow)

PTFE's most well-known limitation is its tendency to "creep," or deform over time under sustained pressure and temperature. This can cause the sealing pressure on a flange to decrease, potentially leading to leaks.

This characteristic requires proper installation procedures, including controlled torque and, in some critical applications, periodic re-torquing of bolts.

Lower Elasticity vs. Elastomers

Compared to rubber-based elastomers, PTFE is a much more rigid material. It has very little "springiness" or elastic recovery.

This means it requires smooth, flat, and well-aligned flange surfaces to achieve a perfect seal. It is less forgiving of surface imperfections or equipment vibration than a more flexible elastomeric gasket.

Making the Right Choice for Your Application

Selecting the right gasket involves balancing the need for purity with mechanical performance requirements.

- If your primary focus is absolute purity and chemical resistance: PTFE is the industry-standard starting point, especially for sealing aggressive media or high-purity APIs.

- If your primary focus is sealing older, irregular, or vibrating surfaces: Consider a composite gasket (like PTFE-enveloped elastomer) that combines PTFE's inert surface with a more forgiving core.

- If your primary focus is high-temperature cycling with high pressure: PTFE is an excellent choice, but ensure your team follows strict installation and torque protocols to mitigate the effects of creep.

Ultimately, leveraging PTFE correctly is about understanding its unparalleled purity and accounting for its specific mechanical behavior.

Summary Table:

| Key Property | Benefit in Pharma/Food Industries |

|---|---|

| Chemical Inertness | Prevents reaction with APIs and food products, ensuring product integrity |

| Non-Toxicity | Eliminates contamination risks, meeting strict regulatory standards |

| Temperature & Chemical Resistance | Withstands CIP/SIP procedures and aggressive cleaning agents |

| Non-Stick Surface | Prevents microbial growth and facilitates easy cleaning |

| Reliable Sealing | Maintains leak-free performance in sanitary processing environments |

Ensure your pharmaceutical or food processing applications meet the highest standards of purity and safety with KINTEK's precision PTFE components.

As specialists in manufacturing high-quality PTFE seals, gaskets, liners, and labware, we understand the critical demands of sanitary industries. Our custom fabrication services—from prototypes to high-volume orders—ensure you get reliable, compliant sealing solutions tailored to your specific needs.

Contact us today to discuss how our PTFE expertise can protect your product integrity and streamline your operations!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the two popular material choices for braided packing? PTFE vs. Graphite for Optimal Sealing

- Can PTFE bushes be customized for specific applications? Tailor Geometry, Material, and Surface for Peak Performance

- What are the key properties of PTFE valves? Ensure Purity, Safety, and Reliability in Demanding Processes

- What are the two major subcomponents of PTFE pneumatic valve assemblies? Achieve Reliable Corrosive Fluid Control

- What advantages does the steel backing provide in PTFE-lined bearings? Achieve High Load Capacity & Superior Heat Dissipation

- What are the advantages of Teflon encapsulated o-rings? Superior Chemical & Temperature Resistance

- What are the different forms of PTFE sheet gasket materials? Select the Right PTFE for Your Sealing Needs

- In which industries are PTFE ball valves commonly used? Essential for Chemical Resistance & Purity