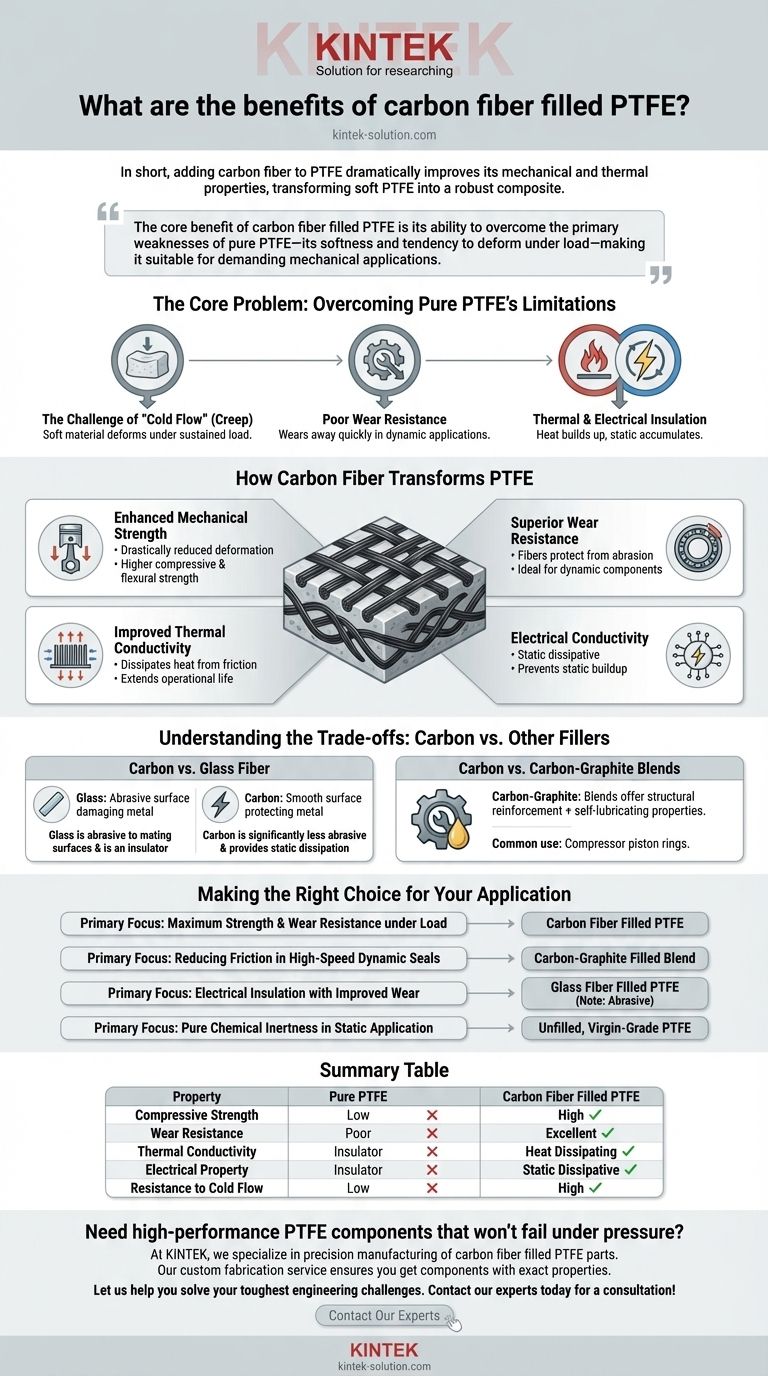

In short, adding carbon fiber to PTFE dramatically improves its mechanical and thermal properties. This enhancement transforms the soft, deformable nature of pure PTFE into a robust composite material with superior strength, wear resistance, and the ability to dissipate heat and static electricity.

The core benefit of carbon fiber filled PTFE is its ability to overcome the primary weaknesses of pure PTFE—its softness and tendency to deform under load—making it suitable for demanding mechanical applications where strength and durability are critical.

The Core Problem: Overcoming Pure PTFE's Limitations

Polytetrafluoroethylene (PTFE) is renowned for its extreme chemical inertness and exceptionally low coefficient of friction. However, in its pure, unfilled state, it suffers from several key weaknesses that limit its use in mechanical systems.

The Challenge of "Cold Flow"

Pure PTFE is a relatively soft material. When subjected to a sustained load, especially at elevated temperatures, it has a tendency to deform permanently, a phenomenon known as "cold flow" or creep.

Poor Wear Resistance

While it is very slick, PTFE's softness means it wears away quickly in dynamic applications like bearings, seals, or wear rings. This results in a short service life and diminished performance over time.

Thermal and Electrical Insulation

PTFE is an excellent thermal and electrical insulator. In applications involving friction, this means heat builds up at the contact surface, which can accelerate wear and degradation. Its insulating nature also allows static electricity to accumulate.

How Carbon Fiber Transforms PTFE

Adding carbon fiber as a filler directly addresses these limitations. The fibers act as a reinforcing skeleton within the softer PTFE matrix, fundamentally changing the material's behavior under stress.

Enhanced Mechanical Strength

Carbon fibers provide a significant boost to the composite's structural integrity. This results in drastically reduced deformation under heavy loads and much higher compressive strength and flexural strength.

The material becomes more rigid and better suited for load-bearing applications.

Superior Wear Resistance

The hard carbon fibers protect the softer PTFE from abrasion. This creates a composite with excellent wear resistance, making it ideal for components like piston rings, bearings, and dynamic seals that experience constant movement.

Improved Thermal Conductivity

Unlike pure PTFE, carbon is an effective thermal conductor. This property allows the composite to dissipate heat away from friction points, preventing overheating and extending the operational life of the component.

Electrical Conductivity

Carbon's conductive nature makes the resulting composite static dissipative. This is a critical feature in applications where a buildup of static electricity could be hazardous or interfere with sensitive electronics.

Understanding the Trade-offs: Carbon vs. Other Fillers

Carbon is a high-performance filler, but it's important to understand how it compares to other common options, such as glass fiber.

Carbon vs. Glass Fiber

Glass fiber also improves wear resistance and reduces cold flow. However, glass is highly abrasive and can damage the mating surfaces (like metal shafts) it runs against.

Carbon is significantly less abrasive than glass, making it a better choice for preserving the integrity of the entire mechanical system. Furthermore, glass is an electrical insulator, whereas carbon provides the benefit of static dissipation.

Carbon vs. Carbon-Graphite Blends

For applications where lubricity is the absolute priority, a carbon-graphite blend is often used. Graphite is an excellent dry lubricant that further reduces the coefficient of friction.

This blend combines the structural reinforcement of carbon with the enhanced self-lubricating properties of graphite, making it a common choice for components like compressor piston rings.

Making the Right Choice for Your Application

Selecting the right material requires matching the filler's properties to the specific demands of your environment.

- If your primary focus is maximum strength and wear resistance under load: Standard carbon fiber filled PTFE is the superior choice for its high compressive strength and durability.

- If your primary focus is reducing friction in high-speed, dynamic seals: A carbon-graphite filled blend often provides the best balance of wear resistance and self-lubrication.

- If your primary focus is electrical insulation with improved wear: Glass fiber filled PTFE is a viable option, but you must account for its abrasive nature on mating parts.

- If your primary focus is pure chemical inertness in a static application: Unfilled, virgin-grade PTFE remains the ideal material when mechanical properties are not a concern.

Ultimately, choosing the right filler transforms PTFE from a specialized sealing material into a versatile and robust engineering plastic.

Summary Table:

| Property | Pure PTFE | Carbon Fiber Filled PTFE |

|---|---|---|

| Compressive Strength | Low | High |

| Wear Resistance | Poor | Excellent |

| Thermal Conductivity | Insulator | Heat Dissipating |

| Electrical Property | Insulator | Static Dissipative |

| Resistance to Cold Flow | Low | High |

Need high-performance PTFE components that won't fail under pressure?

At KINTEK, we specialize in precision manufacturing of carbon fiber filled PTFE parts for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication service, from prototypes to high-volume orders, ensures you get components with the exact mechanical and thermal properties your application requires.

Let us help you solve your toughest engineering challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability