The suitability of Polytetrafluoroethylene (PTFE) for structural bearings is rooted in a rare combination of properties that solve two conflicting engineering demands simultaneously. Its extremely low coefficient of friction allows for nearly unimpeded movement, while its high compressive strength enables it to support immense vertical loads. Coupled with its self-lubricating nature and environmental resilience, PTFE becomes an ideal material for these critical components.

PTFE resolves the core challenge of structural engineering: how to support the immense, static weight of a structure while also accommodating dynamic movements like thermal expansion, contraction, and seismic shifts, all without requiring ongoing maintenance.

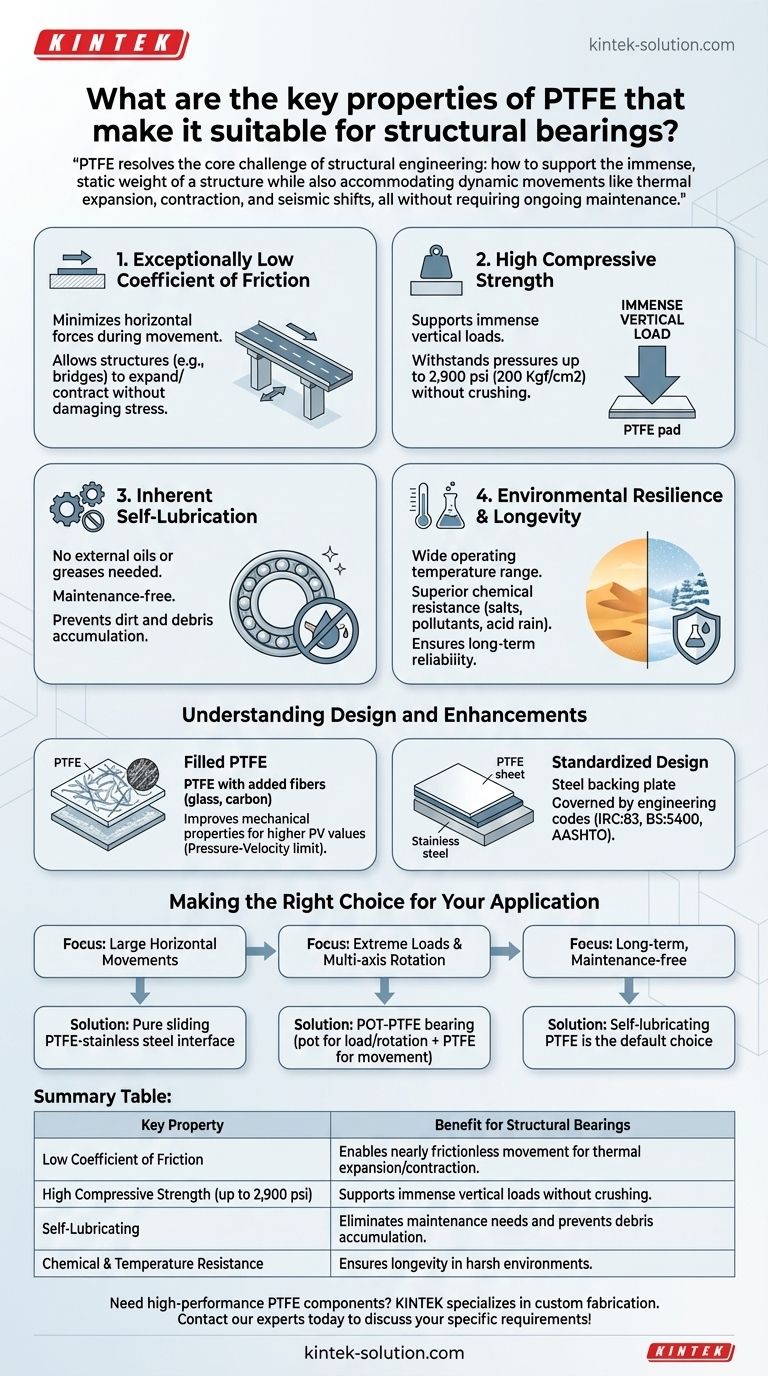

The Core Functional Properties of PTFE Bearings

A structural bearing's primary job is to transfer massive loads while allowing for controlled movement. The material properties of PTFE are uniquely suited to meet these dual requirements.

Exceptionally Low Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. This property is paramount for a structural bearing.

It minimizes the horizontal forces that are transferred between the structure and its foundation during movement. When paired with a polished stainless steel plate, as is common in bearing design, this friction is reduced even further.

This allows massive structures like bridges to expand and contract with temperature changes without building up damaging stress in the structural elements.

High Compressive Strength

While it enables movement, the bearing must first and foremost support the structure's weight. PTFE exhibits excellent compressive strength, capable of withstanding pressures up to 2,900 psi (200 Kgf/cm2).

This capacity allows a relatively small bearing pad to safely transfer enormous vertical loads from the superstructure (e.g., the bridge deck) to the substructure (the piers).

This strength ensures the material will not crush or deform under the constant, immense pressure of the structure it supports.

Inherent Self-Lubrication

PTFE is inherently self-lubricating, meaning it does not require any external oils or greases to maintain its low-friction properties.

This is a critical advantage for infrastructure, where bearings are often installed in locations that are difficult or impossible to access for regular maintenance.

The absence of external lubricants also prevents the attraction and accumulation of dirt and debris, which could otherwise compromise the bearing's performance and shorten its lifespan.

Environmental Resilience and Longevity

Structural bearings are exposed to the elements for decades. PTFE's material stability ensures it can perform its function reliably over the entire life of the structure.

Wide Operating Temperature Range

PTFE remains stable and maintains its key properties across a very wide spectrum of temperatures.

This ensures the bearing will perform consistently and predictably, whether it is installed in a hot desert climate or a region with freezing winters.

Superior Chemical Resistance

PTFE is chemically inert and highly resistant to attack from nearly all chemicals, including salts, pollutants, and acid rain.

This resilience prevents material degradation over time, ensuring the bearing's longevity and structural integrity even in harsh or corrosive industrial and marine environments.

Understanding Design and Enhancements

While pure PTFE is highly effective, its properties can be enhanced, and its application is governed by strict engineering standards.

The Role of Fillers

For especially demanding applications, filled PTFE is used. By adding reinforcing agents like glass fiber, carbon, or bronze to the PTFE resin, its mechanical properties are improved.

Specifically, filled PTFE can handle a much higher PV value (Pressure-Velocity limit), which is the measure of a bearing's ability to withstand a combination of high loads and movement speeds.

Standardized Design and Construction

PTFE bearings are not simply blocks of material. In a typical sliding bearing, a thin sheet of PTFE is bonded to a steel backing plate.

This assembly slides against a polished stainless-steel plate, which is welded to the opposing structural element, creating the low-friction interface that accommodates movement.

The design and implementation of these components are governed by rigorous engineering codes, such as IRC:83, BS:5400, and AASHTO, to ensure safety and reliability.

Making the Right Choice for Your Application

Your specific structural goal will determine how you leverage PTFE's properties.

- If your primary focus is accommodating large horizontal movements: The pure sliding action of a PTFE-stainless steel interface is the most direct and effective solution.

- If your primary focus is supporting extreme vertical loads with multi-axis rotation: A POT-PTFE bearing, which combines a high-capacity pot bearing for load and rotation with a PTFE slider for movement, is the superior choice.

- If your primary focus is long-term, maintenance-free performance: The self-lubricating and chemically inert nature of PTFE makes it the default choice for critical infrastructure designed to last for decades.

Ultimately, PTFE's unique material profile provides engineers with a reliable, durable, and efficient solution to the complex challenge of managing structural loads and movements.

Summary Table:

| Key Property | Benefit for Structural Bearings |

|---|---|

| Low Coefficient of Friction | Enables nearly frictionless movement for thermal expansion/contraction. |

| High Compressive Strength (up to 2,900 psi) | Supports immense vertical loads without crushing. |

| Self-Lubricating | Eliminates maintenance needs and prevents debris accumulation. |

| Chemical & Temperature Resistance | Ensures longevity in harsh environments. |

Need high-performance PTFE components for your structural or industrial application? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders, ensuring your project benefits from PTFE's unique properties. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications