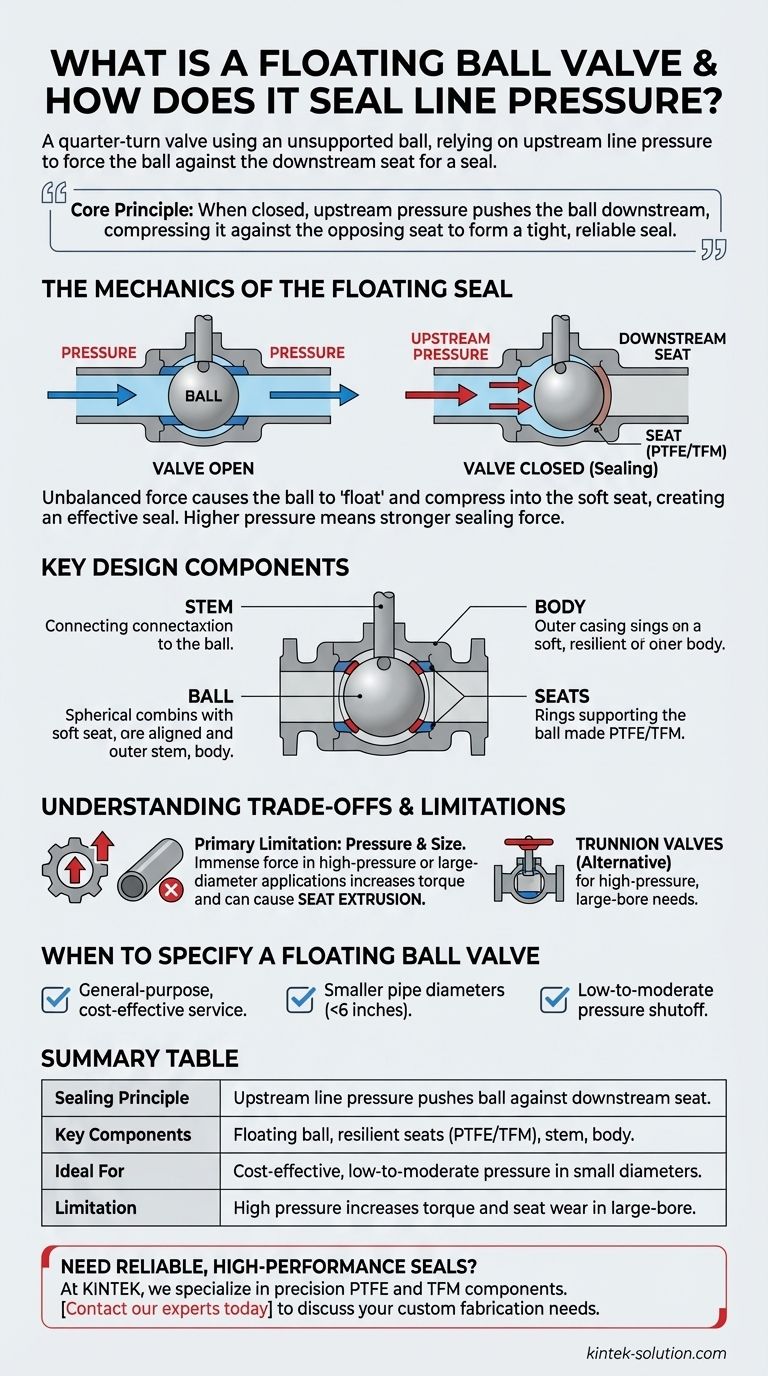

A floating ball valve is a quarter-turn valve that uses an unsupported ball to create a seal. Unlike designs where the ball is mechanically anchored, this valve relies on the upstream line pressure itself to force the free-floating ball against the downstream seat. This simple, pressure-actuated mechanism is what effectively shuts off the flow.

The core principle of a floating ball valve is its use of the process fluid's own force. When closed, upstream pressure pushes the ball downstream, compressing it against the opposing seat to form a tight, reliable seal.

The Mechanics of the Floating Seal

To understand a floating ball valve, you must understand how it leverages system pressure. The design is elegantly simple but relies on a precise interaction between the ball, the seats, and the fluid.

The Role of the Valve Seats

The two valve seats are the critical components that support the ball. They are typically made from soft, resilient materials like PTFE (Teflon) or modified versions like TFM.

These seats perform two functions: they hold the ball in position within the valve body and provide the soft surface needed to create a bubble-tight seal.

How Upstream Pressure Creates the Seal

When the valve is open, pressure is equal on both sides of the ball. However, once the valve is turned to the closed position, this balance is interrupted.

The upstream line pressure now exerts force across the entire exposed surface of the ball, creating a significant net force pushing it in the direction of the flow.

The "Floating" Action in Detail

This unbalanced force causes the ball to "float" or move a very small distance within the valve cavity. It travels until it makes firm contact with the downstream seat.

The force of the line pressure then compresses the ball into this soft seat material, creating an extremely effective seal. The higher the line pressure, the stronger the sealing force becomes.

Key Design Components

The effectiveness of a floating ball valve comes from the synergy of a few core parts working together.

The Ball

The central component is a spherical ball with a hole, or bore, through the center. When the bore is aligned with the pipe, flow is unimpeded. When turned 90 degrees, the solid wall of the ball blocks the flow.

The Seats

As mentioned, the seats are typically rings made of a polymer like PTFE. They are essential for both supporting the ball and providing the sealing surface.

The Stem and Body

The stem connects to the top of the ball, allowing an external handle or actuator to rotate it. The body is the outer casing that contains all the components and withstands the line pressure.

Understanding the Trade-offs

While effective and widely used, the floating ball valve design has inherent limitations that are important to recognize.

The Primary Limitation: Pressure and Size

The reliance on line pressure to seal is also the design's main constraint. In high-pressure or large-diameter applications, the force pushing the ball into the downstream seat can become immense.

This immense force can dramatically increase the torque required to operate the valve. It can also cause premature seat wear or damage, a phenomenon known as seat extrusion. For this reason, floating ball valves are most common in smaller sizes and for moderate pressures.

Comparison to Trunnion Valves

For high-pressure and large-bore applications, a trunnion-mounted ball valve is often used instead. In a trunnion design, the ball is mechanically anchored by top and bottom supports (the trunnion), and the seats are energized to move and seal against the fixed ball. This design manages high forces far more effectively.

When to Specify a Floating Ball Valve

Choosing the correct valve depends entirely on the application's demands.

- If your primary focus is general-purpose, cost-effective service: The simple design and lower component count of a floating ball valve make it an economical and reliable choice for standard, lower-pressure systems.

- If you are working with smaller pipe diameters (e.g., under 6 inches): Floating ball valves are the industry standard for smaller lines where high operating torque from line pressure is not a significant concern.

- If your application requires low-to-moderate pressure shutoff: This design excels in environments where the line pressure is sufficient to create a strong seal but not so high that it damages the seats or makes operation difficult.

By understanding this pressure-actuated sealing principle, you can confidently specify and apply these valves in the scenarios where their design truly excels.

Summary Table:

| Feature | Description |

|---|---|

| Sealing Principle | Upstream line pressure pushes the floating ball against the downstream seat. |

| Key Components | Floating ball, resilient PTFE/TFM seats, stem, and valve body. |

| Ideal For | Cost-effective, low-to-moderate pressure applications in smaller diameters (typically < 6 inches). |

| Limitation | High pressure can increase operating torque and cause seat wear in large-bore applications. |

Need reliable, high-performance seals for your critical valves?

The sealing surfaces inside a valve are paramount to its performance. At KINTEK, we specialize in manufacturing precision PTFE and TFM components—including custom valve seats—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures a bubble-tight seal and long-lasting durability.

Contact our experts today to discuss your custom fabrication needs.

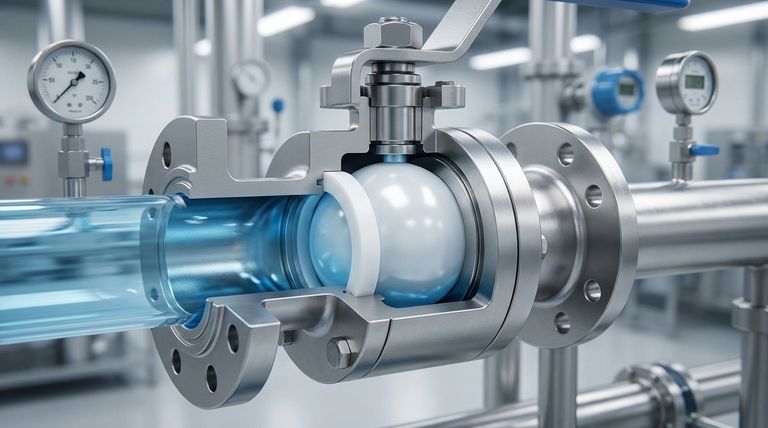

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits