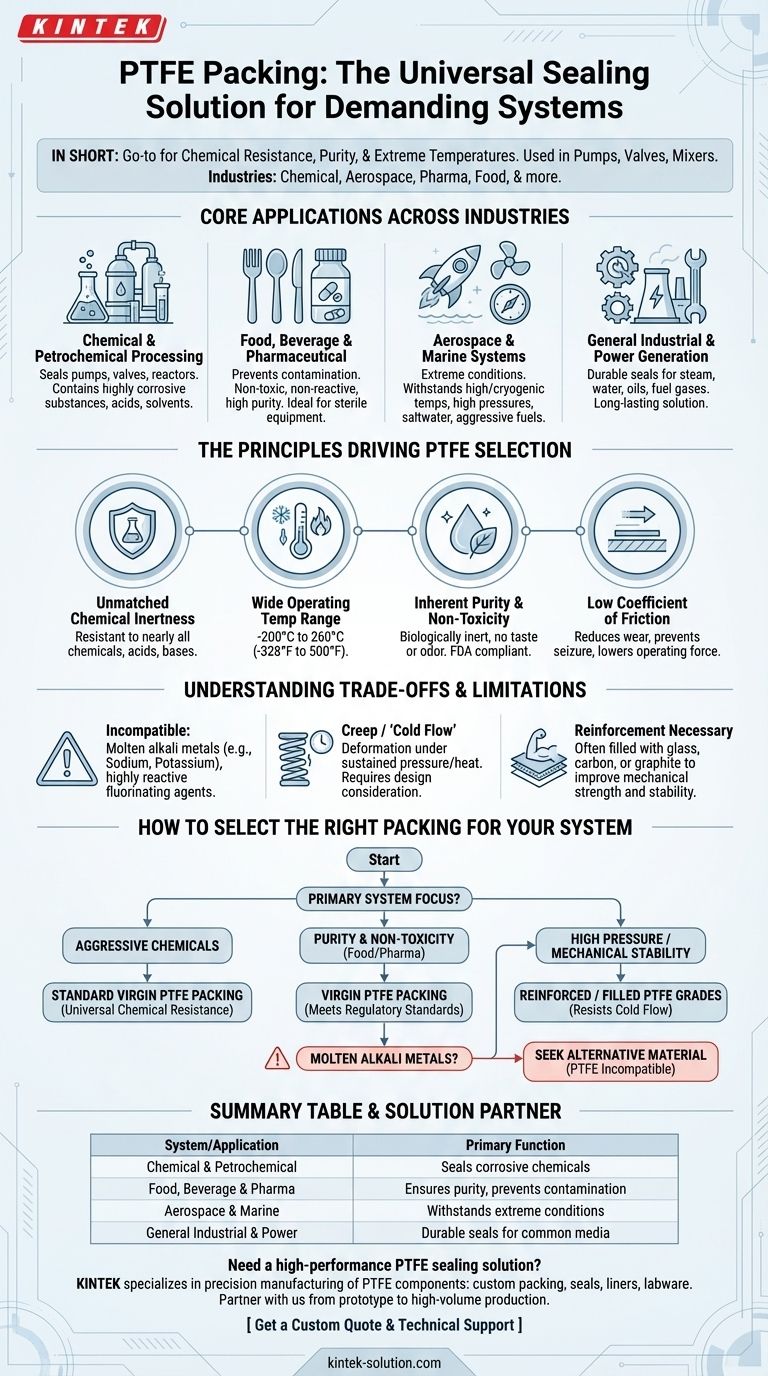

In short, PTFE packing is the go-to sealing solution for systems demanding exceptional chemical resistance, purity, and performance under extreme temperatures. It is found across a vast range of industries, from chemical processing and aerospace to pharmaceutical and food manufacturing, where it is used in equipment like pumps, valves, and mixers to handle aggressive or sensitive media.

The decision to use PTFE packing is fundamentally about managing chemical compatibility and environmental extremes. Its near-universal inertness makes it a default choice for corrosive substances, while its purity and stability make it essential for sensitive applications in the food and medical sectors.

Core Applications Across Industries

PTFE's unique properties make it indispensable in several demanding fields. The application determines the specific form and grade of the material used.

Chemical and Petrochemical Processing

PTFE packing is a cornerstone of the chemical industry. It is used to create reliable seals in pumps, valves, reactors, and mixers.

Its primary function is to contain highly corrosive substances, strong chemicals, oxidizers, solvents, and effluents that would degrade most other sealing materials.

Food, Beverage, and Pharmaceutical Manufacturing

In these industries, preventing contamination is the highest priority. PTFE is non-toxic, non-reactive, and can be manufactured to a high degree of purity.

This makes it ideal for sealing processing equipment where the material will come into contact with consumables or pharmaceutical products, ensuring sterile and safe conditions.

Aerospace and Marine Systems

Aerospace and marine applications subject components to extreme conditions. PTFE seals are used in actuators, landing gear, fuel systems, and cryogenic valves.

It is specified for its ability to withstand extreme temperatures (both high and cryogenic), high pressures, and corrosive environments like saltwater and aggressive fuels.

General Industrial and Power Generation

Beyond specialized fields, PTFE packing is widely used in general manufacturing and power plants for more common applications.

This includes sealing pumps and valves that handle steam, water, mineral and synthetic oils, and fuel gases, providing a durable and long-lasting sealing solution.

The Principles Driving PTFE Selection

The choice of PTFE is not arbitrary; it is based on a distinct set of material properties that solve specific engineering challenges.

Unmatched Chemical Inertness

PTFE is resistant to nearly all chemicals, acids, and bases. This makes it one of the most reliable materials for handling aggressive media without degrading or leaching.

Wide Operating Temperature Range

PTFE maintains its integrity and properties across a vast temperature spectrum, from cryogenic applications around -200°C (-328°F) up to 260°C (500°F).

Inherent Purity and Non-Toxicity

Virgin PTFE is inherently pure and biologically inert. It imparts no taste, odor, or contaminants, making it compliant with strict food and medical regulations.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is invaluable in dynamic applications like valve stems and rotating pump shafts, as it reduces wear, prevents seizure, and lowers the force needed for operation.

Understanding the Trade-offs and Limitations

While incredibly versatile, PTFE is not a universal solution. Understanding its limitations is critical for proper application.

Incompatibility with Specific Elements

PTFE's legendary chemical resistance has a few exceptions. It is not suitable for use with molten alkali metals (like sodium or potassium) or highly reactive fluorinating agents.

Tendency to Creep or "Cold Flow"

Under sustained pressure, especially at elevated temperatures, standard PTFE can deform over time. This phenomenon, known as creep or cold flow, can lead to a loss of seal integrity if not accounted for in the design.

Material Reinforcement is Often Necessary

To counteract its tendency to creep, PTFE is often filled or reinforced with other materials like glass fiber, carbon, or graphite. These filled grades offer improved mechanical strength and dimensional stability but may alter the material's chemical resistance or purity.

How to Select the Right Packing for Your System

Choosing the correct PTFE packing requires matching the material grade to the system's primary demand.

- If your primary focus is handling aggressive chemicals: Standard virgin PTFE packing is an excellent choice due to its near-universal chemical resistance.

- If your primary focus is purity and non-toxicity (food/pharma): Virgin PTFE packing is ideal, as it meets stringent regulatory standards for contact with consumables.

- If your primary focus is high-pressure or mechanical stability: Consider reinforced or filled PTFE grades, which are specifically designed to resist cold flow and deformation under load.

- If your system involves molten alkali metals: You must seek an alternative material, as PTFE is chemically incompatible and will fail.

Ultimately, understanding both PTFE's exceptional strengths and its specific limitations is the key to engineering a reliable and long-lasting sealing solution.

Summary Table:

| System / Application | Primary Function of PTFE Packing |

|---|---|

| Chemical & Petrochemical Processing | Seals pumps, valves, and reactors handling corrosive chemicals and solvents. |

| Food, Beverage & Pharmaceutical | Ensures purity and prevents contamination in sterile processing equipment. |

| Aerospace & Marine Systems | Withstands extreme temperatures, high pressures, and corrosive environments. |

| General Industrial & Power Generation | Provides durable seals for steam, water, oils, and fuel gases. |

Need a high-performance PTFE sealing solution for your system?

KINTEK specializes in the precision manufacturing of PTFE components, including custom packing, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we deliver the chemical resistance, purity, and thermal stability your application demands.

We partner with you from prototype to high-volume production to ensure a perfect fit and reliable performance. Contact us today to discuss your specific requirements and let our experts provide a solution tailored to your needs.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the melting point of PTFE and its usable temperature range? Master the Thermal Limits for Your Application

- What are PTFE bushes and where are they commonly used? Solve Friction, Chemical, and Temperature Challenges

- Are PTFE and graphite packing self-lubricating? Choose the Right Seal for Your Application

- In which industries are PTFE/PFA lined ball valves commonly used? Essential for Corrosive & High-Purity Fluids

- What are the thermal properties of PTFE that make it ideal for seals? Ensuring Reliability in Extreme Conditions

- What are the non-stick properties of PTFE plugs useful for? Ensuring Purity & Easy Maintenance

- What is PTFE and why is it suitable for O-rings? Achieve Unmatched Chemical & Temperature Resistance

- How do PTFE expansion bellows perform under extreme temperature conditions? Ensure System Integrity from -200°C to 260°C