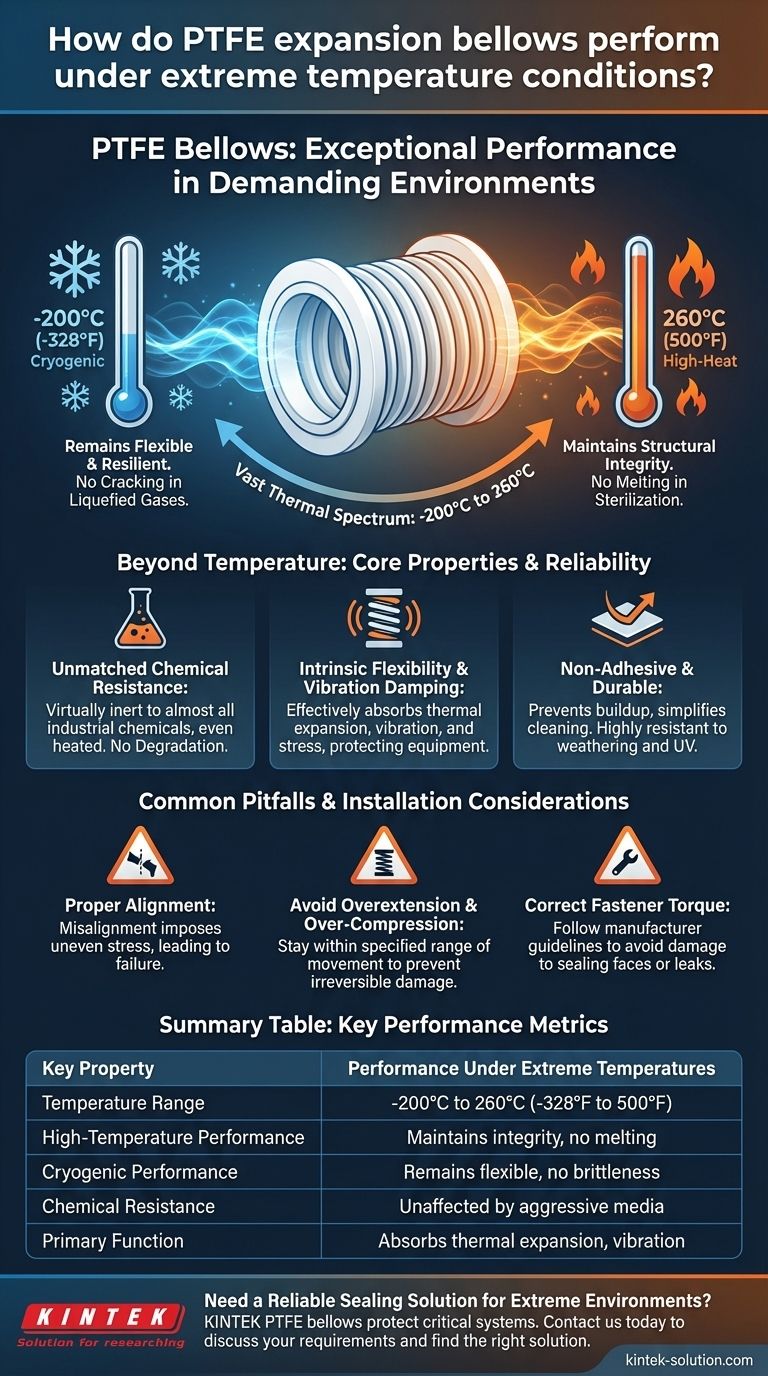

In demanding industrial environments, Polytetrafluoroethylene (PTFE) expansion bellows exhibit exceptional performance under extreme temperature conditions. They are engineered to operate reliably across a vast thermal spectrum, from cryogenic lows of -200°C (-328°F) to high-heat applications reaching 260°C (500°F). This stability ensures they do not crack, melt, or lose their essential flexibility within this specified range.

The true value of PTFE bellows lies not just in their wide temperature tolerance, but in their unique ability to maintain elite chemical resistance and mechanical flexibility at those temperature extremes. This combination is what makes them a definitive solution for ensuring system integrity and safety.

Why PTFE Excels in Extreme Temperatures

The material science of PTFE is central to its performance. Unlike many polymers that become brittle in the cold or degrade with heat, PTFE’s molecular structure is uniquely stable.

The Operational Temperature Range

PTFE bellows are rated for a continuous service range from -200°C to 260°C (-328°F to 500°F). This capability covers the majority of industrial thermal cycling requirements.

Performance at High Temperatures

At the upper end of its range, PTFE maintains its structural integrity without melting or deteriorating. This makes it ideal for applications like high-temperature sterilization in pharmaceutical production, where other materials would fail.

Performance at Cryogenic Temperatures

At the lower end, PTFE avoids the brittleness that causes other materials to crack or fracture. Its ability to remain flexible in cryogenic conditions is critical for applications involving liquefied gases and other super-cooled media.

Beyond Temperature: Core Properties That Ensure Reliability

Temperature tolerance alone is not enough. The reliability of PTFE bellows comes from a combination of properties that work in concert.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This resistance is not compromised by temperature, ensuring that the bellow will not degrade when handling aggressive media, even when heated.

Intrinsic Flexibility and Vibration Damping

The primary function of an expansion bellow is to absorb movement. PTFE’s flexibility allows it to effectively accommodate thermal expansion, vibration, and system stress, protecting rigid piping and connected equipment from damage.

Non-Adhesive Surface

PTFE has a non-stick surface, which is a significant advantage in many processes. This property prevents material buildup and blockages, simplifies cleaning, and is essential in sanitary applications.

Environmental Durability

PTFE is highly resistant to weathering and UV radiation. This ensures a long shelf life and consistent performance, even when installed in harsh outdoor or challenging environmental conditions.

Common Pitfalls and Installation Considerations

While PTFE is a robust material, the performance of an expansion bellow is heavily dependent on proper installation and operation within its design limits.

The Criticality of Proper Alignment

Misalignment between the bellow and the connecting pipelines is a primary cause of premature failure. This imposes uneven stress on the convolutions, leading to fatigue and wear.

Avoiding Overextension and Over-Compression

Every expansion bellow has a specified range of movement. Extending or compressing it beyond these manufacturer guidelines will cause irreversible damage and compromise its integrity.

Correct Fastener Torque

During installation, it is crucial to follow the manufacturer's guidelines for torquing the fasteners. Overtightening can damage the bellow's sealing faces, while under-tightening can lead to leaks.

Making the Right Choice for Your Application

To leverage PTFE bellows effectively, align their specific strengths with your primary operational goal.

- If your primary focus is high-purity or sanitary processes: The combination of high-temperature tolerance for sterilization and a non-adhesive surface makes PTFE the ideal choice.

- If your primary focus is handling aggressive chemicals: PTFE's unmatched chemical inertness across its entire temperature range ensures maximum safety and system longevity.

- If your primary focus is managing vibration and thermal cycling: The material's inherent flexibility is crucial for absorbing system movement and preventing stress-related failures in your piping.

By understanding both its exceptional properties and its installation requirements, you can confidently specify PTFE expansion bellows to build a more resilient and reliable system.

Summary Table:

| Key Property | Performance Under Extreme Temperatures |

|---|---|

| Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| High-Temperature Performance | Maintains structural integrity without melting |

| Cryogenic Performance | Remains flexible, avoiding brittleness and cracking |

| Chemical Resistance | Unaffected by aggressive media across the entire range |

| Primary Function | Absorbs thermal expansion, vibration, and system stress |

Need a Reliable Sealing Solution for Extreme Environments?

PTFE expansion bellows from KINTEK are engineered to protect your critical systems in the semiconductor, medical, laboratory, and industrial sectors. We combine precision manufacturing with deep material expertise to deliver components that ensure safety, purity, and longevity—even under the most demanding thermal and chemical conditions.

Whether you require a standard product or a custom-fabricated solution from prototype to high-volume production, we are here to help you build a more resilient system.

Contact KINTEK today to discuss your application requirements and discover the right PTFE bellow solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Does carbon fiber-filled PTFE damage shafts? Ensure Longevity with Proper Material Pairing

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why are PTFE O-rings suitable for high-temperature applications? Unmatched Thermal & Chemical Stability

- What industries benefit from the high-temperature and high-pressure resistance of PTFE bellows? Ensure System Integrity in Demanding Applications

- What is the significance of biocompatibility in PTFE fasteners for medical devices? Ensure Patient Safety and Device Reliability

- Why are PTFE Lip Seals considered a game-changer in rotary applications? Unlock Unmatched Performance & Reliability

- In which industries are EPTFE gaskets commonly used? Critical Sealing Solutions for Demanding Environments

- Are PTFE encapsulated O-rings compliant with industry standards? Ensure Purity & Performance in Critical Applications