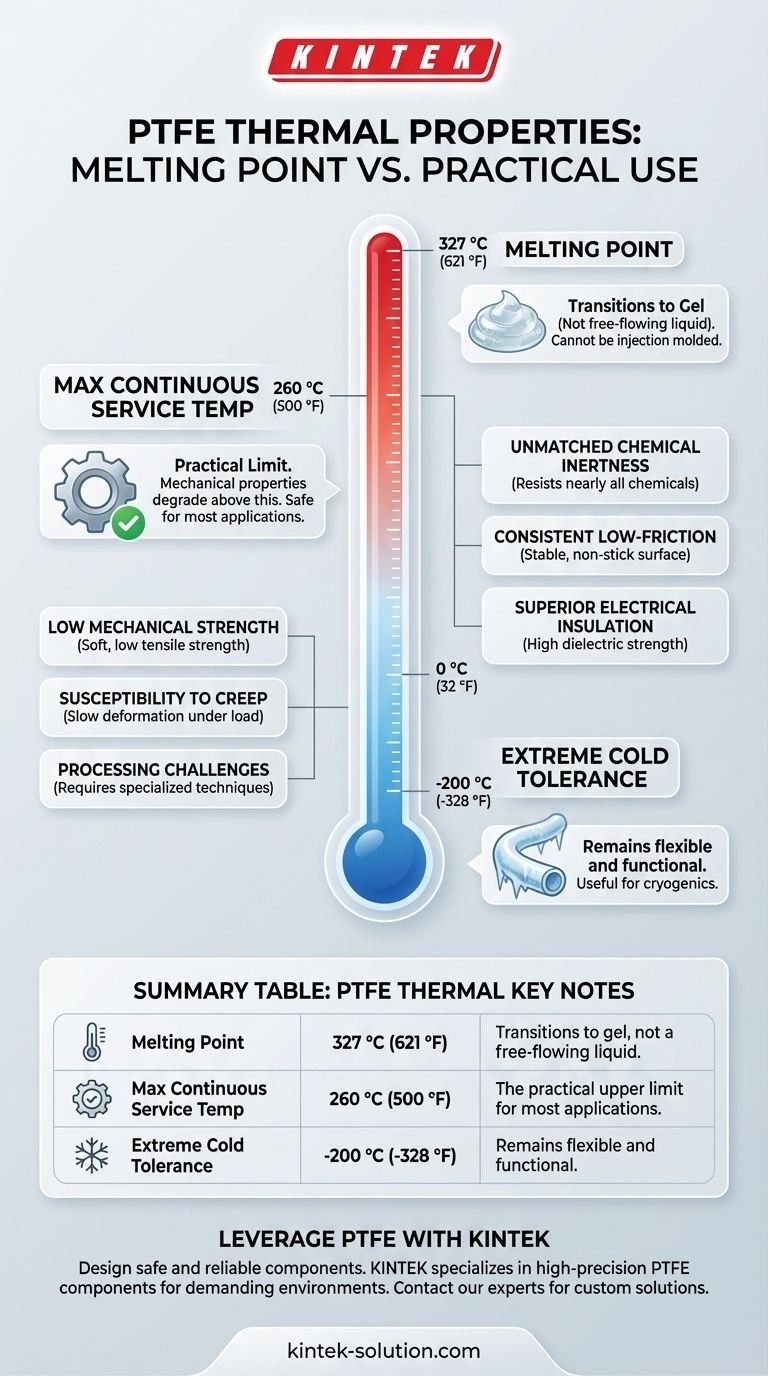

In short, Polytetrafluoroethylene (PTFE) has a melting point of approximately 327 °C (621 °F). However, its practical maximum continuous service temperature—the limit for most real-world applications—is significantly lower, around 260 °C (500 °F). This distinction is critical for safe and effective engineering design.

The true value of PTFE is not just its high melting point, but its unique combination of extreme thermal stability, chemical inertness, and low friction that it maintains across an exceptionally wide and useful temperature range.

Deconstructing PTFE's Thermal Performance

Understanding the difference between a material's melting point and its practical service temperature is fundamental. For PTFE, these two figures tell very different stories about its capabilities.

The Melting Point: A Technical Threshold

The widely cited melting point for PTFE is 327 °C (621 °F). Unlike many plastics that transition to a free-flowing liquid, PTFE does not.

Instead, at this temperature, it becomes a translucent, high-viscosity gel. It does not flow easily, which is why it cannot be processed using conventional melt-processing techniques like injection molding.

The Continuous Service Temperature: The Practical Limit

For engineers and designers, the most important number is the maximum continuous service temperature, which is 260 °C (500 °F).

Above this temperature, PTFE begins to lose its mechanical properties, even though it has not yet melted. The material softens, its tensile strength decreases, and it becomes more susceptible to wear and deformation under load.

Extreme Cold Tolerance: A Unique Advantage

PTFE's performance is equally impressive at the other end of the spectrum. It remains highly functional and flexible down to cryogenic temperatures of approximately -200 °C (-328 °F).

This ability to resist becoming brittle at extreme cold makes it a valuable material for aerospace and low-temperature industrial applications.

Why Temperature is Only Part of the Story

PTFE's thermal stability is the foundation for its other elite properties. The strong carbon-fluorine bonds that give it heat resistance are also responsible for its other signature characteristics.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents across its entire operating temperature range. This makes it an ideal choice for seals, gaskets, and linings in aggressive chemical environments, from freezing cold to 260 °C.

Consistent Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any known solid. This non-stick, low-friction behavior is stable across its temperature range, making it essential for high-temperature bearings, non-stick coatings, and low-resistance seals.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. Its ability to maintain these insulating properties without degrading at high temperatures makes it a critical material in high-performance wiring, cables, and electronic components.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's thermal and chemical properties are world-class, its mechanical properties introduce important design constraints.

Low Mechanical Strength

PTFE is a relatively soft material with low tensile strength and rigidity compared to engineering plastics like PEEK or nylon. It is not suitable for applications requiring high structural loads.

Susceptibility to Creep

Under a constant compressive load, especially at elevated temperatures, PTFE is prone to "creep," or slow deformation over time. This must be accounted for in the design of seals and gaskets to prevent eventual failure.

Processing Challenges

The same thermal stability that makes PTFE so useful also makes it difficult to process. Its high viscosity at its melting point means it cannot be injection molded, requiring specialized and often more costly manufacturing techniques like compression molding and sintering.

Making the Right Choice for Your Application

Selecting the right material requires balancing its strengths and weaknesses against the demands of your specific goal.

- If your primary focus is high-temperature stability: Design around the continuous service limit of 260 °C (500 °F), not the melting point.

- If your primary focus is chemical resistance: PTFE is a reliable choice across its entire usable temperature range, from cryogenic lows to its upper service limit.

- If your application involves significant mechanical load: Consider "filled" grades of PTFE (e.g., glass- or carbon-filled) to improve strength and creep resistance, or evaluate other high-performance polymers.

Understanding these thermal nuances is key to leveraging PTFE's remarkable properties for safe and reliable performance in the most demanding environments.

Summary Table:

| Property | Value | Key Note |

|---|---|---|

| Melting Point | 327 °C (621 °F) | Transitions to a gel, not a free-flowing liquid |

| Max Continuous Service Temp | 260 °C (500 °F) | The practical upper limit for most applications |

| Extreme Cold Tolerance | -200 °C (-328 °F) | Remains flexible and functional |

Leverage PTFE's Exceptional Thermal Properties for Your Project

Understanding the precise thermal limits of PTFE is crucial for designing safe and reliable components. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine deep material expertise with precision production and custom fabrication services, from prototypes to high-volume orders, ensuring your components perform flawlessly in demanding thermal and chemical environments.

Ready to design with confidence? Contact our experts today to discuss your specific requirements and how our PTFE solutions can bring unmatched thermal stability, chemical inertness, and low friction to your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What material is ideal for rotary shaft lip seals and why? PTFE Offers Superior Performance

- Why is ePTFE a good choice for fragile or damaged flanges? Protect Your Flanges with Low-Stress Sealing

- Why is selecting the right PTFE packing important? Ensure Reliable Sealing & Prevent Costly Failures

- What long-term benefits do Teflon bearings provide? Slash Maintenance Costs & Boost Reliability

- What are the benefits of using PTFE lined pipes? Achieve Unmatched Chemical Resistance and Flow Efficiency

- How does PTFE impregnated with silicone oil improve gland packing performance? Enhance Sealing with Low Friction

- How is Teflon coating applied in the construction industry? Enhancing Safety and Durability in Building Components

- What are the common applications of PTFE bars? Key Uses in High-Performance Industries