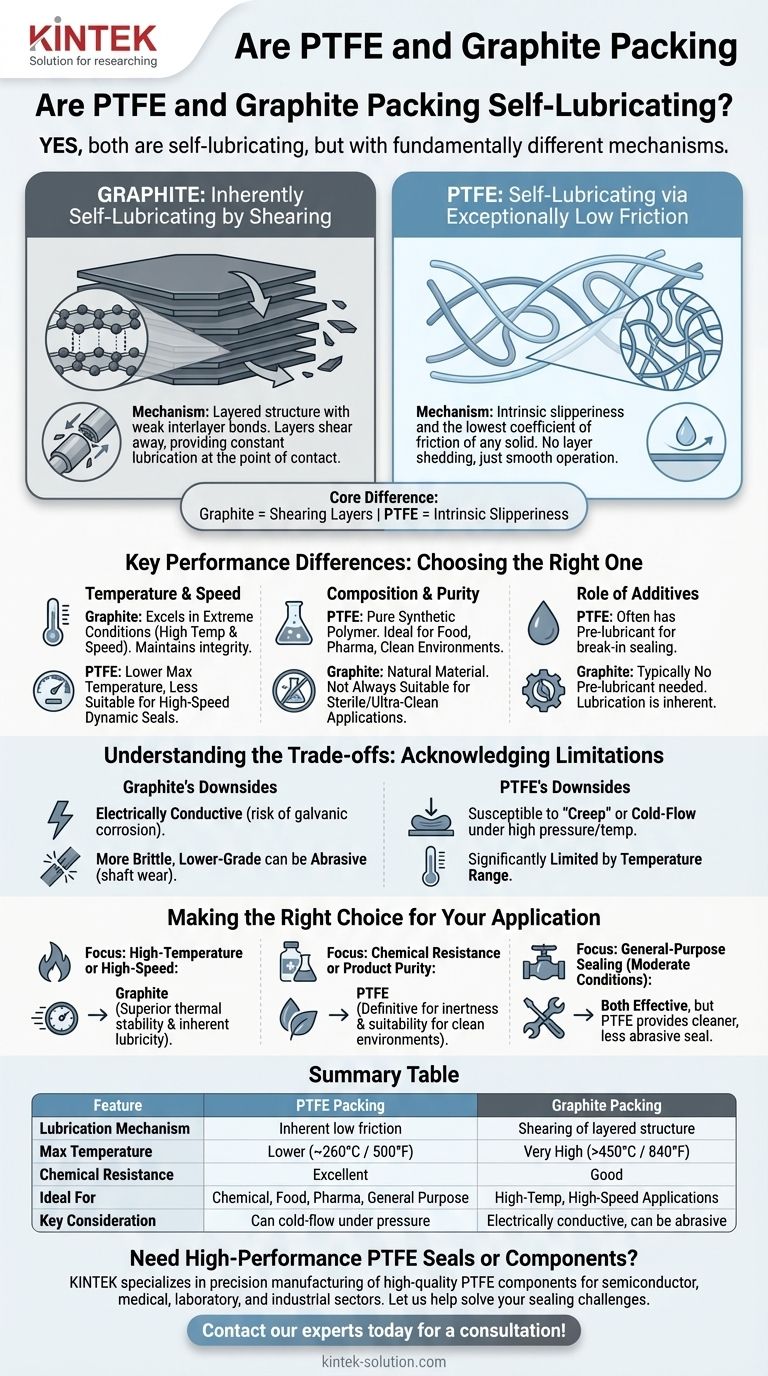

Yes, both PTFE and graphite packing are considered self-lubricating, but their properties and the mechanisms behind their low friction are fundamentally different. Graphite is inherently self-lubricating due to its physical structure, while PTFE's self-lubricating nature comes from its exceptionally low coefficient of friction.

The core difference is this: Graphite's lubrication comes from its layered structure shearing away, while PTFE's comes from its inherent "slipperiness," which makes it one of the lowest-friction solid materials known.

The Nature of Self-Lubrication

Understanding how each material achieves its low-friction properties is key to choosing the right one for your application. The mechanisms are distinct and lead to different performance characteristics.

How Graphite Works

Graphite is a natural, inorganic form of pure carbon. Its atoms are arranged in layers.

These layers are weakly bonded and can easily slide over one another, a process known as shearing. This shearing action provides constant lubrication at the point of contact, making graphite inherently self-lubricating.

How PTFE Works

PTFE (polytetrafluoroethylene) is a synthetic polymer, widely known by the brand name Teflon®. It does not rely on shedding layers.

Instead, its self-lubricating property comes from having the lowest coefficient of friction of any known solid material. This intrinsic slipperiness prevents sticking and ensures smooth operation without the need for external lubricants.

Key Performance Differences

While both reduce friction, their other properties dictate where they are best used. The choice between them is rarely just about lubrication.

Temperature and Speed

Graphite excels in extreme conditions. It maintains its integrity and lubricating properties at very high temperatures and high shaft speeds where PTFE would fail.

PTFE has a much lower maximum operating temperature and can be less suitable for high-speed dynamic seals.

Composition and Purity

PTFE packing is a pure synthetic polymer, making it ideal for applications where contamination is a concern, such as in food processing or pharmaceutical industries.

Graphite is a natural material. While it can be highly refined, it is not always suitable for sterile or ultra-clean environments.

The Role of Additives

While inherently low-friction, PTFE packing is often manufactured with a pre-lubricant. This break-in lubricant helps with initial sealing and reduces friction until the packing has fully seated.

Graphite packing typically does not require this, as its lubricating mechanism is part of its core structure.

Understanding the Trade-offs

Neither material is a perfect solution for every scenario. Acknowledging their limitations is critical for reliable performance.

Graphite's Downsides

Graphite is electrically conductive, which can be an issue in applications where galvanic corrosion is a risk.

It can also be more brittle than PTFE, and lower-grade graphite can be abrasive, potentially causing shaft or stem wear over time.

PTFE's Downsides

The primary limitation of PTFE is its tendency to "creep" or cold-flow under high pressure and temperature, which can lead to a loss of sealing force over time.

Its performance is also significantly limited by temperature compared to graphite.

Making the Right Choice for Your Application

Your operational environment is the deciding factor. Base your decision on the specific demands of the equipment.

- If your primary focus is high-temperature or high-speed performance: Graphite is the superior choice due to its thermal stability and inherent lubricity under extreme conditions.

- If your primary focus is chemical resistance or product purity: PTFE is the definitive option for its chemical inertness and suitability for clean environments like food, beverage, or pharma.

- If your primary focus is general-purpose sealing in moderate conditions: Both materials can be effective, but PTFE often provides a cleaner and less abrasive seal for common pump and valve applications.

Ultimately, selecting the correct packing material depends on a clear understanding of your system's temperature, pressure, speed, and chemical environment.

Summary Table:

| Feature | PTFE Packing | Graphite Packing |

|---|---|---|

| Lubrication Mechanism | Inherent low friction | Shearing of layered structure |

| Max Temperature | Lower (~260°C / 500°F) | Very High (>450°C / 840°F) |

| Chemical Resistance | Excellent | Good |

| Ideal For | Chemical, Food, Pharma, General Purpose | High-Temp, High-Speed Applications |

| Key Consideration | Can cold-flow under pressure | Electrically conductive, can be abrasive |

Need High-Performance PTFE Seals or Components?

Choosing the right packing material is critical for your system's efficiency and longevity. KINTEK specializes in the precision manufacturing of high-quality PTFE components, including seals, liners, and custom labware.

We serve the specialized needs of the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise ensures you get a component perfectly suited to your application's temperature, pressure, and chemical environment.

Let us help you solve your sealing challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE an excellent choice for gaskets, rings, and bearings? Unlock Unmatched Reliability with KINTEK PTFE

- Why are PTFE lined valves considered a reliable choice for industrial processes? Achieve Unmatched Chemical Resistance & Longevity

- What are the properties of stainless steel-reinforced PTFE? A High-Performance Composite for Demanding Seals

- What alternative material is gaining popularity for hydrogenerator thrust bearings? PTFE for Superior Performance & Reliability

- What are the key benefits of PTFE V-rings? Achieve Superior Sealing in Extreme Conditions

- What are the key differences between PTFE and EPDM valve seats? Choose the Right Material for Your Application

- What are the advantages of Teflon square bars? Solve Extreme Engineering Challenges

- What makes PTFE lined valves suitable for handling aggressive media? Superior Chemical Resistance for Harsh Fluids