At its core, a PTFE bush is a high-performance, non-metallic bearing engineered from Polytetrafluoroethylene. These components, often called line bearings, are specifically used in applications where traditional metal bushes would fail due to high friction, chemical attack, or extreme temperatures. They function as a low-wear, self-lubricating sleeve between moving parts.

PTFE bushes are not just a plastic alternative to metal; they are a strategic solution for engineering challenges that demand exceptional chemical inertness, extremely low friction, and a wide operating temperature range where conventional materials would seize or degrade.

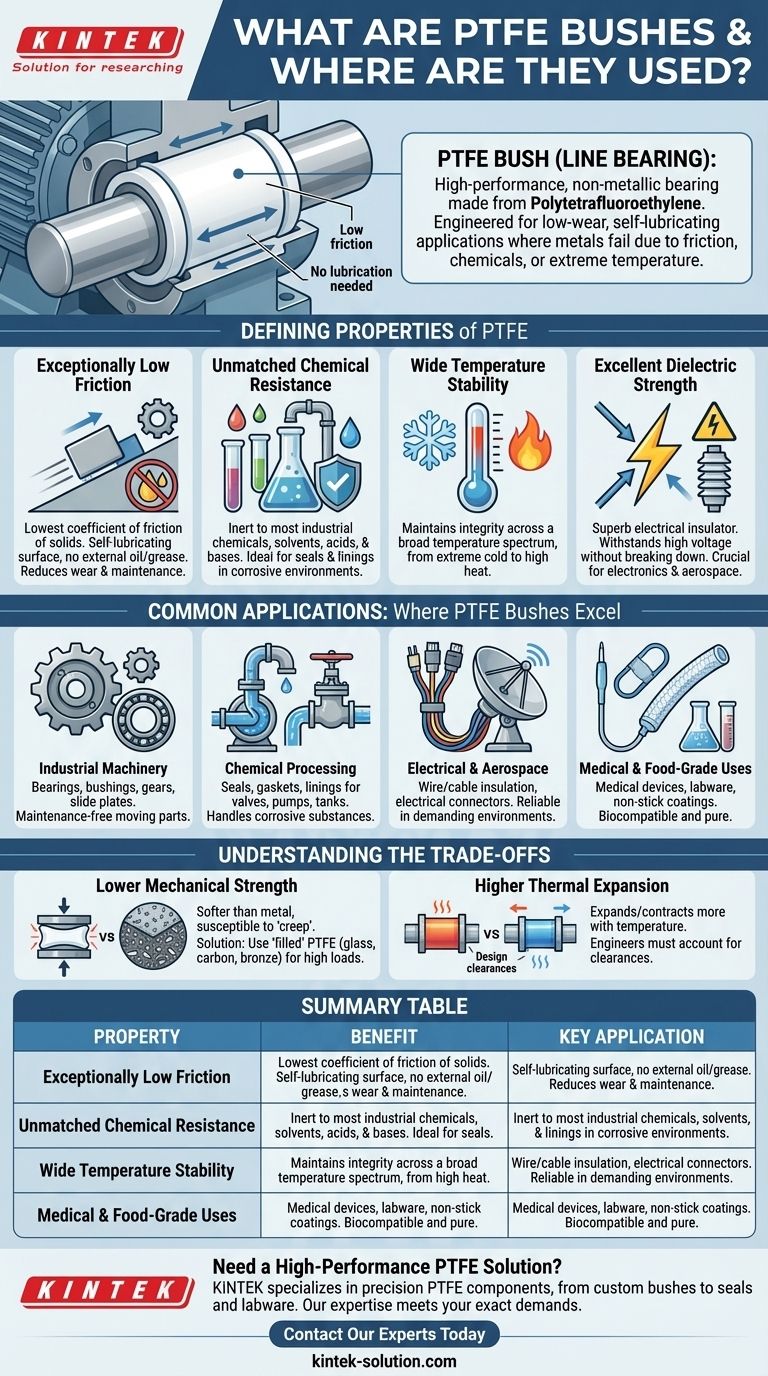

The Defining Properties of PTFE

To understand where to use a PTFE bush, you must first understand the remarkable properties of the material itself. These characteristics are the reason it is chosen for such demanding roles.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This creates a "non-stick" or self-lubricating surface.

In a mechanical assembly, this means moving parts can slide against a PTFE bush with minimal resistance and without the need for external grease or oil, significantly reducing wear and maintenance.

Unmatched Chemical Resistance

PTFE is almost completely inert, meaning it does not react with the vast majority of industrial chemicals, solvents, acids, and bases.

This property makes it the default choice for equipment that handles corrosive materials, such as seals and linings in chemical pumps, valves, and transport pipes.

Wide Temperature Stability

PTFE maintains its integrity and properties across an exceptionally broad temperature spectrum, from cryogenic lows to high-heat environments.

This thermal stability allows PTFE bushes to perform reliably in applications that experience significant temperature fluctuations, from aerospace components to industrial processing equipment.

Excellent Dielectric Strength

PTFE is a superb electrical insulator, meaning it does not conduct electricity. It can withstand a very high voltage before it begins to break down.

This makes it invaluable for insulating high-frequency wires and cables, especially in critical computer and aerospace applications where signal integrity is paramount.

Common Applications: Where PTFE Bushes Excel

The unique combination of these properties makes PTFE bushes and related components essential across several key industries.

Industrial Machinery

In general machinery, PTFE is used for bearings, bushings, gears, and slide plates. Its self-lubricating nature is ideal for creating maintenance-free moving parts that resist wear.

Chemical Processing

Due to its chemical inertness, PTFE is critical for seals, gaskets, and linings for valves, pumps, pipes, and tanks. It ensures the integrity of equipment handling highly corrosive substances.

Electrical and Aerospace

The material's dielectric strength and temperature resistance make it a top choice for wire and cable insulation and electrical connectors, ensuring reliable performance in demanding environments.

Medical and Food-Grade Uses

PTFE is biocompatible and meets stringent purity standards. This allows for its use in medical devices like catheters, surgical grafts, and laboratory containers, as well as for non-stick coatings on cookware.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Lower Mechanical Strength

Compared to metals, PTFE is a relatively soft material. It has lower compressive strength and can be susceptible to "creep," or cold flow, where the material slowly deforms under a constant load.

For high-load structural applications, a metal bearing is often superior. However, this weakness can be mitigated by using "filled" PTFE, which incorporates materials like glass, carbon, or bronze to improve strength and wear resistance.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals do. Engineers must account for this by designing in appropriate clearances to prevent parts from binding or becoming loose.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is reducing friction in a clean environment: A standard, unfilled PTFE bush offers self-lubricating properties that eliminate the need for external lubricants.

- If your primary focus is handling corrosive chemicals: PTFE's unmatched chemical inertness makes it the definitive choice for seals, linings, and components in aggressive media.

- If your primary focus is a high-load or abrasive environment: Consider a filled-PTFE composite, which enhances mechanical strength and wear resistance while retaining key benefits.

- If your primary focus is electrical insulation at extreme temperatures: PTFE's high dielectric strength and thermal stability make it ideal for critical wiring and connectors.

Understanding these core principles allows you to move beyond simply choosing a material and begin engineering a more effective and reliable solution.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Low Friction | Self-lubricating, reduces wear | Bearings, slide plates |

| Chemical Resistance | Inert to most acids, solvents | Seals, valves, pump linings |

| Temperature Stability | Performs from cryogenic to high heat | Aerospace, industrial equipment |

| Dielectric Strength | Excellent electrical insulator | Wire/cable insulation, connectors |

Need a High-Performance PTFE Solution?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom bushes, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your components meet the exact demands of your application.

Contact our experts today to discuss how our custom PTFE fabrication can solve your unique engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- In which applications are anti-static PTFE bellows used? Essential for Static-Sensitive Industries

- What role does chemical stability play in the performance of Teflon gland fillers? Ensure Long-Term Reliability in Harsh Environments

- What are the applications of expanded PTFE? Unlock Versatility for Demanding Seals & Filters

- How should designs account for Teflon's high creep rate? Master PTFE Design for Long-Term Reliability

- How does the manufacturing of PTFE expansion joints accommodate industry-specific needs? Tailor-Made Solutions for Your Application

- Why are PTFE extruded rods used in chemical processing equipment? For Superior Chemical Resistance and Purity

- What are the applications of Teflon bearings in extreme environments? Ensure Reliability from -400°F to +550°F

- What role do PTFE guide strips play in the aerospace industry? Ensure Safety and Reliability in Critical Systems