The defining thermal properties of PTFE that make it an exceptional material for seals are its incredibly wide operating temperature range, a high melting point, and its inherent stability against thermal degradation. This unique combination allows PTFE seals to maintain their physical integrity and sealing performance in extreme conditions where most other materials would quickly fail.

The core reason PTFE excels in thermal sealing applications is not just its tolerance for high and low temperatures, but its ability to resist physical breakdown and property changes when cycled between those extremes, ensuring consistent, long-term reliability.

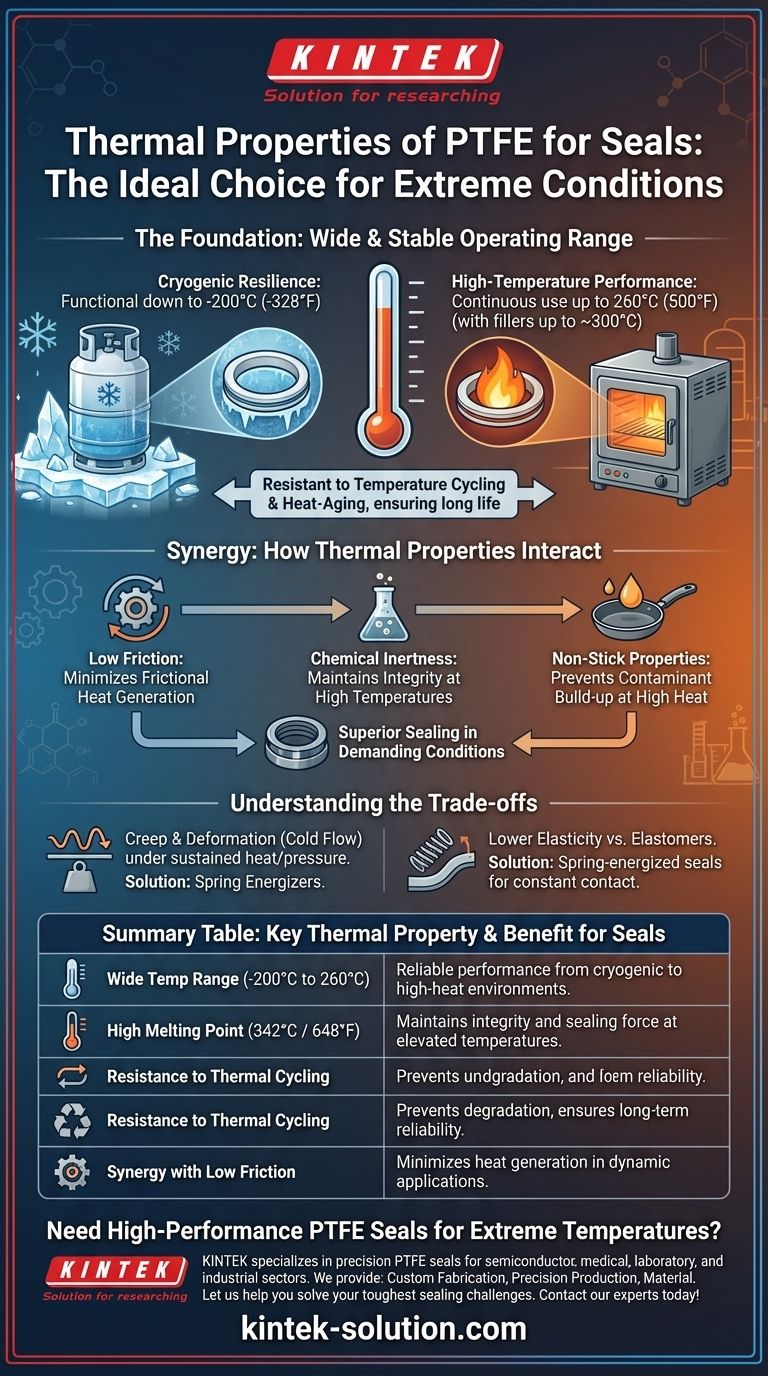

The Foundation: A Wide and Stable Operating Range

The primary thermal advantage of PTFE stems from its ability to function reliably across a vast temperature spectrum, from cryogenic lows to significant industrial heat.

High-Temperature Performance

PTFE has a very high melting point of 342°C (648°F). This allows seals made from virgin PTFE to be used continuously in environments up to 260°C (500°F).

When enhanced with specific fillers, this continuous operating temperature can be extended even further, approaching 300°C (572°F). This makes it ideal for automotive, aerospace, and oil and gas applications.

Cryogenic Resilience

On the other end of the spectrum, PTFE maintains its properties in extremely cold conditions, remaining functional down to -200°C (-328°F).

Unlike many elastomers and plastics that become brittle and crack at low temperatures, PTFE retains enough flexibility to provide a reliable seal in cryogenic applications.

Stability Across Temperature Cycles

A critical, often overlooked property is PTFE's resistance to heat-aging and degradation from temperature cycling.

The material does not harden, crack, or lose its essential sealing characteristics even after repeated exposure to fluctuating temperatures. This ensures a long and predictable service life.

How Thermal Properties Interact with Other Key Characteristics

PTFE's thermal stability does not exist in a vacuum. It works in synergy with its other unique properties to create a superior sealing solution, especially under demanding conditions.

The Role of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating characteristic is crucial because it minimizes frictional heat generation in dynamic or rotary applications.

This prevents the seal from contributing to its own thermal failure, a common problem with higher-friction materials.

Chemical Inertness at High Temperatures

Many materials lose their chemical resistance as temperatures rise. PTFE, however, maintains its exceptional chemical inertness even at elevated temperatures.

This allows it to seal aggressive acids, solvents, and bases in high-temperature chemical processing or industrial environments without degrading.

Maintaining Non-Stick Properties

PTFE's non-stick surface prevents contaminants, sludge, or process media from adhering to the seal lip. At high temperatures, this property is vital because it stops materials from "baking on" to the seal, which could compromise its function and lead to leaks.

Understanding the Trade-offs

While its thermal properties are exceptional, PTFE is not a universal solution. Understanding its limitations is key to successful implementation.

The Impact of Fillers

Using fillers to boost high-temperature performance can be effective, but it can also alter other properties. A filler that increases heat resistance might slightly decrease chemical compatibility or increase the coefficient of friction. The formulation must be matched to the specific application.

Creep and Deformation

Under a combination of high heat and sustained pressure, PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time. Proper seal design, often incorporating spring energizers, is critical to counteract this tendency and maintain a consistent sealing force.

Lower Elasticity vs. Elastomers

Compared to rubber or other elastomers, PTFE has very little "memory" or elasticity. It does not rebound to its original shape as readily. This is why many PTFE seals are spring-energized to ensure the seal lip stays in constant contact with the sealing surface, especially during temperature fluctuations that cause materials to expand and contract.

Making the Right Choice for Your Application

Selecting the right seal material requires matching its properties to your primary operational challenge.

- If your primary focus is an extreme temperature range (hot or cold): PTFE is an unparalleled choice due to its operational stability from -200°C to 260°C.

- If your application involves aggressive chemicals at high temperatures: PTFE's combined thermal stability and chemical inertness provide a level of reliability that few other materials can match.

- If you need long-term reliability with frequent temperature fluctuations: PTFE's resistance to heat-aging and thermal cycling ensures a long service life without degradation of its sealing properties.

Ultimately, PTFE's thermal characteristics provide a robust foundation for creating seals that remain reliable and effective under the most demanding conditions.

Summary Table:

| Key Thermal Property | Benefit for Seals |

|---|---|

| Wide Temp Range (-200°C to 260°C) | Reliable performance from cryogenic to high-heat environments. |

| High Melting Point (342°C / 648°F) | Maintains integrity and sealing force at elevated temperatures. |

| Resistance to Thermal Cycling | Prevents degradation and ensures long-term reliability. |

| Synergy with Low Friction | Minimizes heat generation in dynamic applications. |

Need High-Performance PTFE Seals for Extreme Temperatures?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals deliver unmatched reliability, chemical resistance, and long-term performance, even under the most demanding thermal cycles.

We provide:

- Custom Fabrication: From prototypes to high-volume production.

- Precision Production: Ensuring exact specifications for critical applications.

- Material Expertise: Optimizing PTFE and filler formulations for your specific needs.

Let us help you solve your toughest sealing challenges. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions