In short, PTFE/PFA lined ball valves are standard in any industry that handles highly corrosive or high-purity fluids. Their primary applications are found in chemical processing, petrochemicals, pharmaceuticals, water treatment, and metallurgical operations where standard metal valves would quickly corrode and fail.

The core principle is simple: these valves place an inert, chemically resistant barrier between a corrosive fluid and the valve's structural body. This makes them the definitive choice for applications where media purity and equipment longevity are non-negotiable.

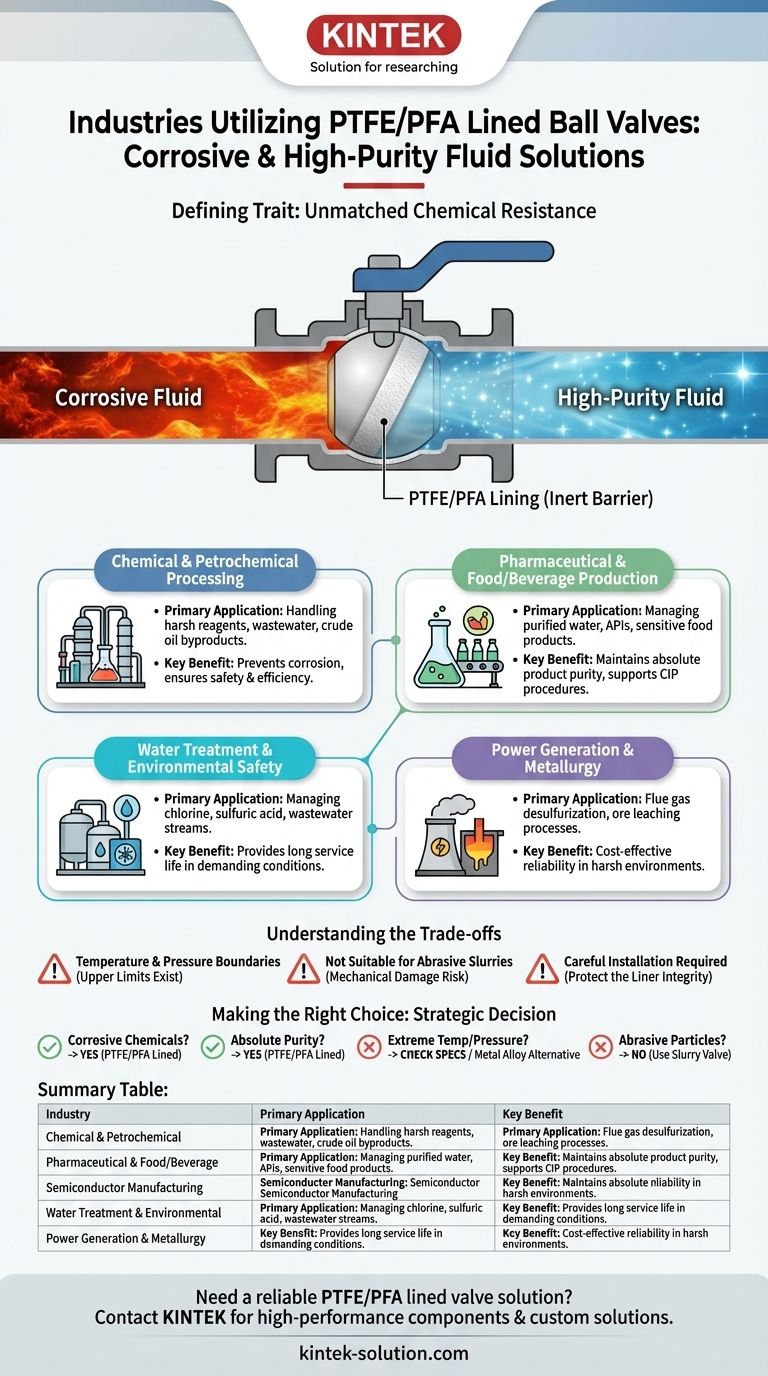

The Defining Trait: Unmatched Chemical Resistance

The selection of a lined valve is almost always driven by the need to manage aggressive media. The fluoropolymer linings, primarily Polytetrafluoroethylene (PTFE) and Perfluoroalkoxy (PFA), are nearly immune to chemical attack.

Why an Inert Lining is Critical

A lined valve's main purpose is to isolate the fluid from the valve's metal body, typically made of carbon steel or stainless steel. This prevents two critical failures: the corrosion of the valve itself and the contamination of the process media.

Handling Aggressive Acids, Bases, and Solvents

Industries like chemical processing, fertilizer production, and pulp and paper routinely use substances that would destroy standard valves in hours. PTFE/PFA linings provide a robust, long-term solution for controlling these media without degradation.

Maintaining Purity in Sensitive Processes

In pharmaceutical, food and beverage, and semiconductor manufacturing, the fluid must remain absolutely pure. The inert nature of the liner ensures that nothing leaches from the valve body into the media, preventing product contamination.

A Breakdown of Key Industrial Applications

While the principle is universal, the specific problems solved by PTFE/PFA lined valves vary by industry.

Chemical and Petrochemical Processing

This is the largest area of use. These valves are essential for managing the flow of harsh reagents, processing wastewater streams, and handling byproducts from crude oil refining. Their reliability is critical for plant safety and efficiency.

Pharmaceutical and Food Production

Hygiene and non-contamination are paramount. Lined valves are used to handle purified water, active pharmaceutical ingredients (APIs), and food products like juices or dairy. The smooth, non-stick surface of the liner also facilitates clean-in-place (CIP) procedures.

Water Treatment and Environmental Safety

Municipal and industrial water treatment facilities rely on strong chemicals like chlorine and sulfuric acid. Lined valves provide the necessary corrosion resistance for a long service life in these demanding applications.

Power Generation and Metallurgy

These heavy industries often use corrosive chemicals for processes like flue gas desulfurization or ore leaching in mining and foundry operations. Lined valves provide a cost-effective and reliable method for fluid control in these harsh environments.

Understanding the Trade-offs

While highly effective, lined valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Boundaries

PTFE and PFA have upper temperature and pressure limits. While suitable for a vast range of applications, they cannot replace high-performance metal alloy valves in extreme high-temperature or high-pressure services.

Not Suitable for Abrasive Slurries

The primary weakness of a polymer lining is its susceptibility to mechanical damage. Fluids containing abrasive solids or slurries can erode or scratch the lining, leading to premature failure. In such cases, a different valve design is required.

Careful Installation is Required

The integrity of the lining is everything. During installation, it is crucial to avoid scratching the liner or over-torquing flange bolts, which can deform the sealing surfaces and cause leaks.

Making the Right Choice for Your Application

Selecting the correct valve depends entirely on the specific demands of your process fluid and operating conditions.

- If your primary focus is managing highly corrosive chemicals: A PTFE/PFA lined valve is almost certainly the correct and most cost-effective choice.

- If your primary focus is maintaining absolute product purity: The inertness of a lined valve makes it a superior option for pharmaceutical, food, or semiconductor applications.

- If your primary focus is extreme temperature or pressure: You must carefully check the valve's specifications and consider specialized metal alloy valves as an alternative.

- If your primary focus is controlling fluids with abrasive particles: A lined valve is likely the wrong choice; you should investigate valves specifically designed for slurry service.

Ultimately, choosing a PTFE/PFA lined valve is a strategic decision to ensure safety, purity, and long-term reliability in challenging chemical environments.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Chemical & Petrochemical | Handling harsh reagents, acids, solvents | Prevents corrosion, ensures safety & efficiency |

| Pharmaceutical & Food/Beverage | Managing purified water, APIs, sensitive products | Maintains absolute product purity, supports CIP |

| Semiconductor Manufacturing | Controlling ultra-pure chemicals | Prevents contamination for high-yield production |

| Water Treatment & Environmental | Managing chlorine, sulfuric acid, wastewater | Provides long service life in demanding conditions |

| Power Generation & Metallurgy | Flue gas desulfurization, ore leaching | Cost-effective reliability in harsh environments |

Need a reliable PTFE/PFA lined valve solution for your corrosive or high-purity application?

At KINTEK, we specialize in manufacturing high-performance PTFE and PFA components, including custom-fabricated seals, liners, and labware. Whether you require a standard design or a custom solution—from prototypes to high-volume orders—our precision production ensures your equipment delivers unmatched chemical resistance and maintains critical fluid purity.

Contact us today to discuss your specific requirements and let our experts help you select or design the perfect valve lining for your application in the semiconductor, medical, laboratory, or industrial sectors. Get in touch via our contact form to get started!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained