PTFE balls are foundational components in a range of demanding industries. Their use is most common in chemical processing, food and pharmaceutical manufacturing, and specialized filtering applications where material purity and resilience are non-negotiable.

The widespread use of PTFE balls is a direct result of their unique combination of chemical inertness, high-temperature stability, and extremely low friction. These properties make them one of the few materials that can operate reliably in harsh, sensitive, or high-purity environments.

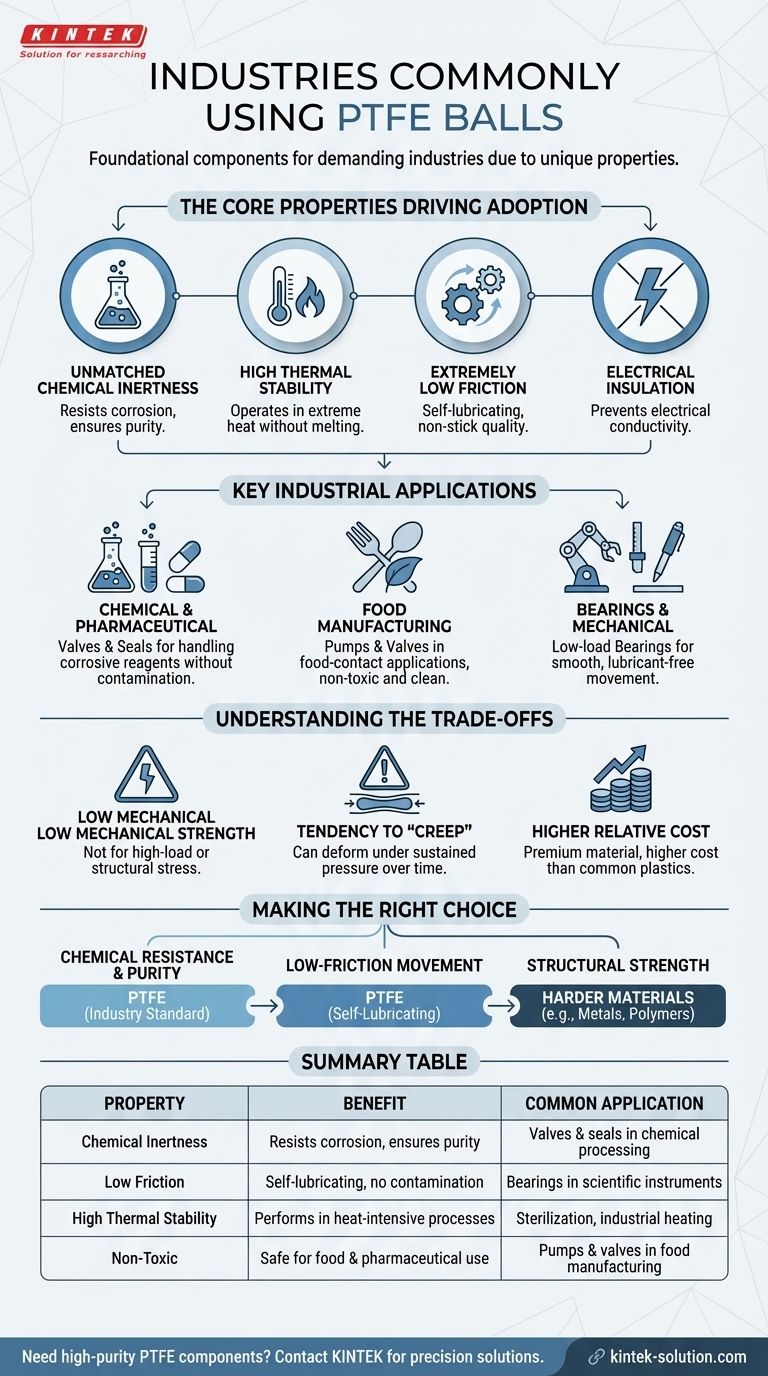

The Core Properties Driving Adoption

To understand why these specific industries rely on Polytetrafluoroethylene (PTFE), we must first look at its fundamental material characteristics.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This means it will not react with, corrode, or contaminate the substances it contacts.

This property is the primary reason for its adoption in aggressive chemical processing and high-purity pharmaceutical work.

High Thermal Stability

This material maintains its integrity and properties across a wide temperature range. It can operate in conditions where many other plastics would melt or become brittle.

This makes it suitable for industrial processes involving heat, such as sterilization or chemical reactions.

Extremely Low Friction (Lubricity)

PTFE has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" or self-lubricating quality.

This is critical for applications like bearings, seals, and valve components, where smooth, repeatable movement is required without external lubricants.

Electrical Insulation

As an excellent electrical insulator, PTFE is also valuable in scientific instruments or specialized industrial equipment where preventing electrical conductivity is necessary.

Key Industrial Applications Explained

These properties translate directly into specific, high-value uses across several sectors.

Chemical and Pharmaceutical Processing

In these fields, purity is paramount. PTFE balls are used in valves and seals to handle highly corrosive reagents and solvents without degrading or leaching impurities into the final product.

Food Manufacturing

The non-toxic and non-stick nature of PTFE makes it ideal for food-contact applications. It is used in valves and pumps that handle food products, ensuring clean operation and preventing contamination.

Bearings and Mechanical Systems

For scientific instruments and industrial machinery, PTFE balls serve as low-load bearings. Their self-lubricating nature reduces wear and eliminates the need for oil or grease that could contaminate a system.

Understanding the Trade-offs

No material is perfect. To make an informed decision, you must be aware of PTFE's limitations.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load or structural applications where it would be subject to significant physical stress or impact.

Tendency to "Creep"

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as creep, must be accounted for in component design.

Higher Relative Cost

Compared to common plastics like polypropylene or nylon, PTFE is a premium material with a higher cost. Its use is justified when its unique properties are essential for performance and safety.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary goal.

- If your primary focus is chemical resistance and purity: PTFE is an industry-standard choice for handling aggressive substances in pharma, chemical, and food-grade systems.

- If your primary focus is low-friction movement: Its self-lubricating properties make it excellent for low-load bearings, valve seats, and seals where smooth operation is key.

- If your primary focus is structural strength under high load: You should evaluate harder materials like metals or specialized engineering polymers, as PTFE's softness is a significant limitation.

Understanding these core properties and trade-offs allows you to specify PTFE balls with confidence where they will truly excel.

Summary Table:

| Property | Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists corrosion, ensures purity | Valves & seals in chemical processing |

| Low Friction | Self-lubricating, no contamination | Bearings in scientific instruments |

| High Thermal Stability | Performs in heat-intensive processes | Sterilization, industrial heating |

| Non-Toxic | Safe for food & pharmaceutical use | Pumps and valves in food manufacturing |

Need high-purity PTFE components for your specialized application?

At KINTEK, we manufacture precision PTFE balls, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get components that meet exact specifications for chemical resistance, purity, and performance.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance your system's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide