In short, the non-stick properties of Polytetrafluoroethylene (PTFE) plugs are critical for ensuring easy installation and removal, preventing cross-contamination between processes, and creating a clean, reliable seal. This unique characteristic is fundamental to their use in sensitive environments like laboratories, chemical processing plants, and industrial piping systems.

The true value of PTFE's non-stick nature is not just convenience; it is a core functional requirement. This property, combined with its extreme chemical and thermal resistance, creates a low-maintenance, high-purity sealing solution that is unmatched in demanding applications.

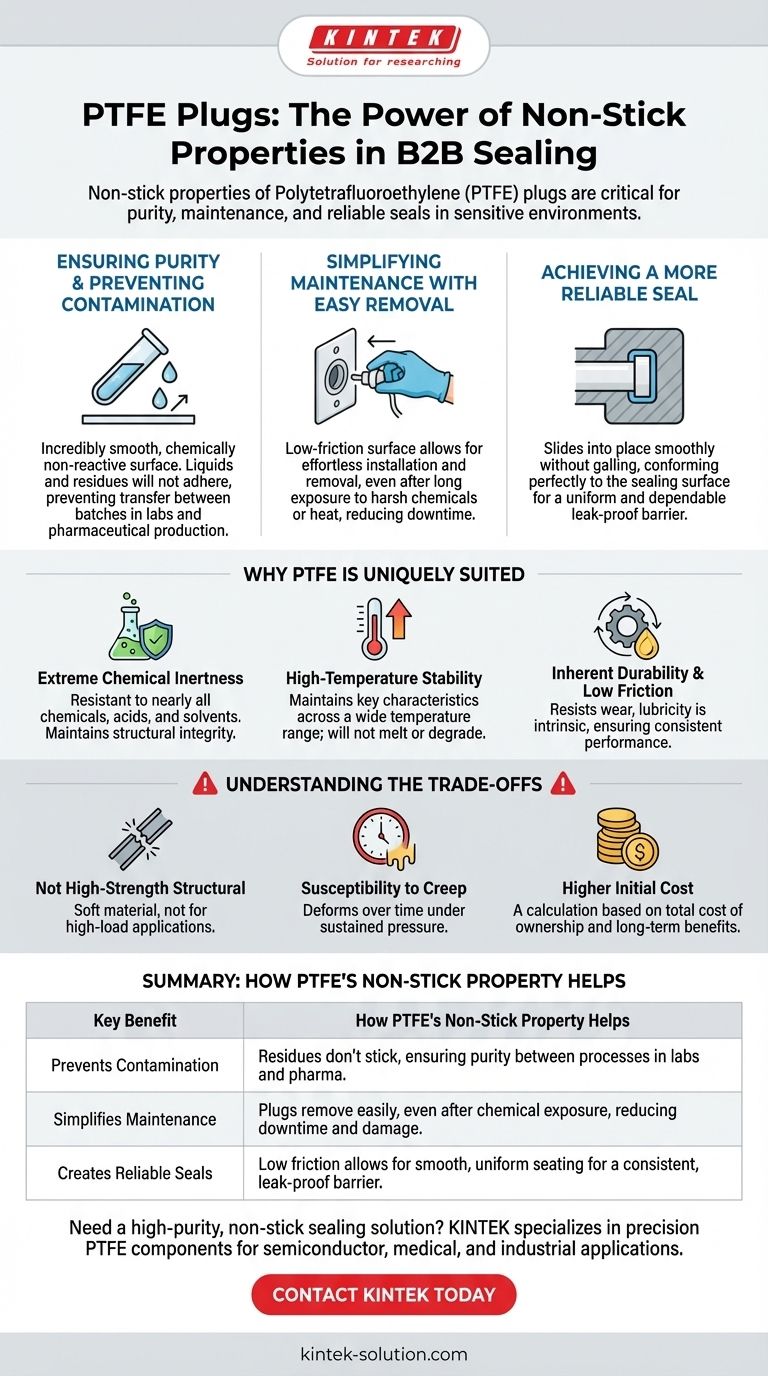

The Role of a Non-Stick Surface in Sealing

A plug's primary job is to create a temporary, leak-proof barrier. The material it's made from dictates how well it performs this job, especially when used repeatedly or with aggressive substances. PTFE's unique surface properties directly address the most common points of failure.

Ensuring Purity by Preventing Contamination

The non-stick surface of a PTFE plug is incredibly smooth and chemically non-reactive. This means that liquids, residues, or reactants from one process will not adhere to the plug's surface.

When the plug is removed, it comes out clean, preventing transfer of materials into the next batch or experiment. This is non-negotiable in pharmaceutical production, food processing, and analytical chemistry, where even trace contamination can ruin results.

Simplifying Maintenance with Easy Removal

Traditional plug materials can bind, swell, or chemically react with the port they are sealing, making them difficult to remove. This often requires excessive force, which can damage both the plug and the expensive equipment it's fitted into.

PTFE's low-friction, non-stick surface ensures it can be installed and removed effortlessly, even after long-term exposure to harsh chemicals or high temperatures. This drastically reduces maintenance time and the risk of equipment damage.

Achieving a More Reliable Seal

The low coefficient of friction allows a PTFE plug to slide into place smoothly without galling or catching. This enables it to conform perfectly to the sealing surface of the port.

The result is a more uniform and dependable seal that is less prone to leaks caused by improper seating.

Why PTFE is Uniquely Suited for This Role

The non-stick characteristic is powerful, but it becomes truly exceptional when combined with PTFE's other inherent properties.

Extreme Chemical Inertness

PTFE is famously resistant to nearly all chemicals, acids, and solvents. A plug that doesn't stick is useless if it dissolves. PTFE's inertness ensures it maintains its structural integrity and non-stick properties when exposed to the most aggressive substances.

High-Temperature Stability

Many industrial and laboratory processes involve extreme heat. PTFE maintains its key characteristics across a wide temperature range, ensuring the plug will not melt, degrade, or become sticky in hot environments.

Inherent Durability and Low Friction

PTFE is a durable material that resists wear from repeated insertion and removal. Its lubricity (low friction) is an intrinsic property, not a coating that can wear off, guaranteeing consistent performance over the plug's entire lifespan.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging the limitations of even a superior material like PTFE.

Not a High-Strength Structural Material

PTFE is relatively soft and is not intended for high-load, structural applications. It excels at sealing and providing a low-friction surface, but it should not be used where high mechanical strength is the primary requirement.

Susceptibility to Creep

Under sustained pressure and temperature, PTFE can slowly deform over time, a phenomenon known as "creep." In high-pressure sealing applications, this must be accounted for in the design of the plug and its housing to ensure a long-term seal.

Higher Initial Cost

As a high-performance polymer, PTFE is typically more expensive upfront than common elastomers or plastics. The decision to use it is a calculation based on total cost of ownership—factoring in reduced contamination, lower maintenance, and greater equipment longevity.

Making the Right Choice for Your Goal

Your specific application will determine which of PTFE's benefits is most critical.

- If your primary focus is purity and preventing cross-contamination: The non-stick surface ensures that no residue is carried from one process to the next, guaranteeing the integrity of your lab results or product batches.

- If your primary focus is process reliability and safety: The combination of chemical inertness and consistent, leak-free sealing makes PTFE the safest choice for handling aggressive or hazardous materials.

- If your primary focus is operational efficiency: The ease of installation and removal reduces downtime, minimizes the risk of equipment damage, and simplifies maintenance protocols.

Choosing the right material is about understanding how its core properties solve your most critical challenges.

Summary Table:

| Key Benefit | How PTFE's Non-Stick Property Helps |

|---|---|

| Prevents Contamination | Residues don't stick, ensuring purity between processes in labs and pharma. |

| Simplifies Maintenance | Plugs remove easily, even after chemical exposure, reducing downtime and damage. |

| Creates Reliable Seals | Low friction allows for smooth, uniform seating for a consistent, leak-proof barrier. |

Need a high-purity, non-stick sealing solution for your application?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and custom plugs. Our expertise ensures your equipment benefits from PTFE's superior non-stick properties, chemical resistance, and thermal stability—critical for semiconductor, medical, laboratory, and industrial applications.

We offer custom fabrication from prototypes to high-volume orders, delivering the reliability and purity your processes demand.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability