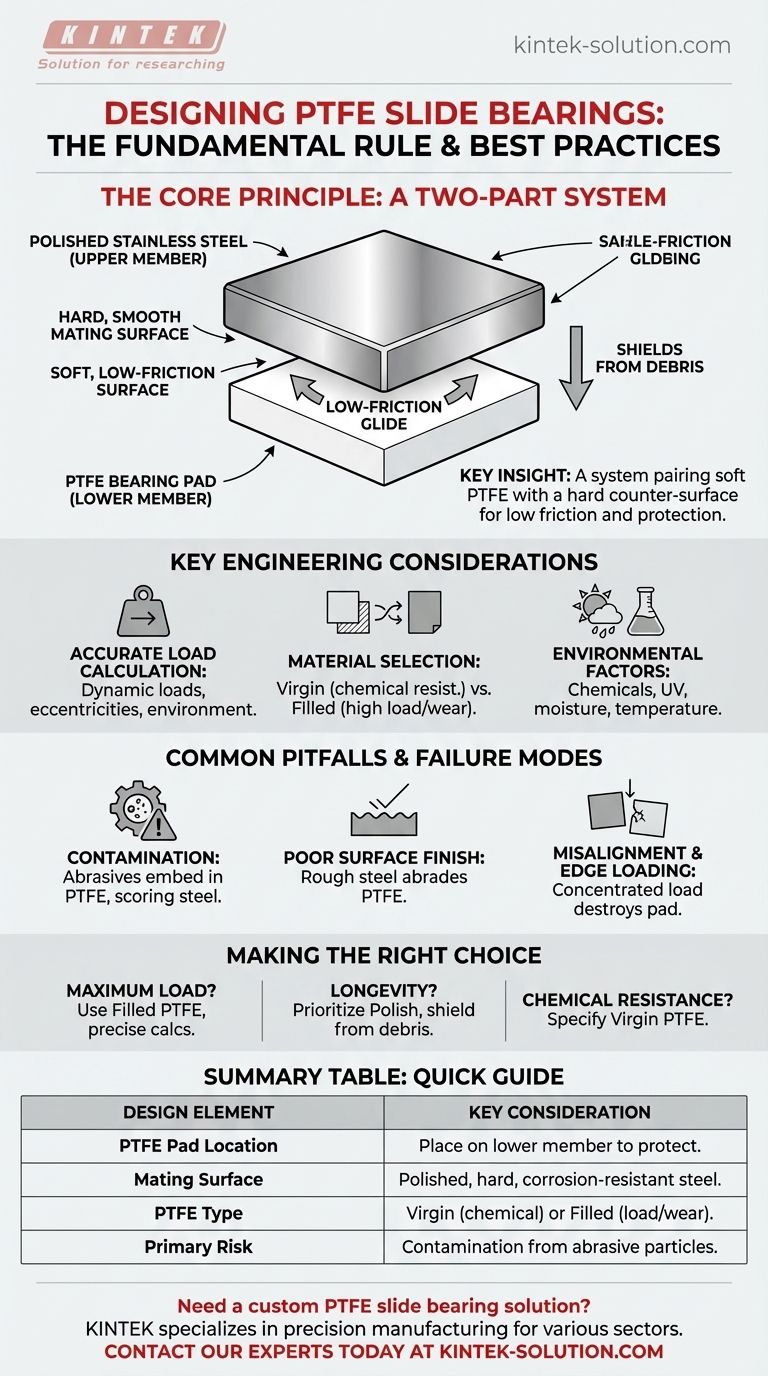

To correctly design a slide bearing using white PTFE, the fundamental rule is to place the PTFE bearing pad on the lower member of the assembly only. This PTFE surface must then mate with an upper member made of polished stainless steel to create a functional, low-friction system.

The core insight is that a PTFE slide bearing is not just a material choice, but a two-part system. The design succeeds by pairing the soft, low-friction PTFE with a hard, smooth, and corrosion-resistant counter-surface, and orienting them to protect the system from contamination and wear.

The Core Principle: A System of Two Surfaces

A successful PTFE slide bearing relies on the interaction between two distinct materials. Understanding why each is chosen and where it is placed is critical to achieving the desired performance and longevity.

Why PTFE is Placed on the Lower Member

Placing the softer PTFE pad on the bottom member is a deliberate design choice for protection.

This orientation shields the PTFE from falling debris, dust, and other environmental contaminants. If placed on top, the PTFE could collect abrasive particles that would damage the opposing steel surface.

Why Polished Stainless Steel is Used for the Upper Member

The upper member must be a hard, exceptionally smooth, and corrosion-resistant material.

Polished stainless steel provides the ideal mating surface, allowing the PTFE to glide with its characteristic minimal friction. Any roughness or imperfection on this surface would rapidly abrade the softer PTFE, increasing friction and causing premature failure.

Key Engineering Considerations

Beyond the core configuration, several factors must be analyzed to ensure the bearing is specified correctly for its intended use.

Accurate Load Calculation

You must calculate the load on the bearing based on its actual operating conditions, not just static weight. Consider dynamic loads, potential eccentricities, and environmental pressures.

Material Selection: Virgin vs. Filled PTFE

Not all PTFE is the same. Virgin PTFE offers the highest chemical resistance and is an excellent electrical insulator.

For applications with higher loads or a need for greater wear resistance, reinforced or filled PTFE (e.g., glass-filled, carbon-filled) is often the superior choice.

Environmental Factors

Assess the operating environment carefully. The design must account for exposure to chemicals, UV radiation, moisture, and temperature extremes, as these can affect not just the PTFE but the entire assembly, including the steel and adhesives.

Common Pitfalls and Failure Modes

Even a correctly specified bearing can fail if certain risks are not mitigated. The configuration is designed to minimize these known failure points.

The Critical Risk of Contamination

The single greatest threat to a PTFE slide bearing is contamination.

If hard, abrasive particles like sand or weld spatter get between the two surfaces, they will embed into the soft PTFE. This turns the bearing pad into a piece of sandpaper, which will then score and destroy the polished stainless steel surface with every movement.

The Impact of Poor Surface Finish

Using a steel surface that is not sufficiently smooth or polished is a common mistake. This creates a high-friction interface that will tear and wear away the PTFE pad, leading to a rapid loss of performance.

Misalignment and Edge Loading

Improper installation that leads to misalignment can concentrate the entire load onto a small edge of the PTFE pad. This "edge loading" creates immense pressure that will destroy the bearing material and cause a complete system failure.

Making the Right Choice for Your Goal

Select and specify your bearing design based on the most critical performance requirement for your project.

- If your primary focus is maximum load capacity: Use a reinforced or filled PTFE and ensure your load calculations are precise and account for all dynamic forces.

- If your primary focus is longevity and low maintenance: Prioritize a high-quality polish on the stainless steel surface and design the surrounding structure to shield the bearing from environmental debris.

- If your primary focus is extreme chemical resistance: Specify virgin PTFE, as it offers the highest degree of chemical inertness.

By treating the bearing as a complete system, you can engineer a solution that delivers reliable, low-friction performance for its entire design life.

Summary Table:

| Design Element | Key Consideration |

|---|---|

| PTFE Pad Location | Must be placed on the lower member to protect from debris. |

| Mating Surface | Requires a polished, hard, corrosion-resistant material like stainless steel. |

| PTFE Type | Virgin PTFE for chemical resistance; filled PTFE (glass, carbon) for higher loads/wear resistance. |

| Primary Risk | Contamination from abrasive particles is the leading cause of failure. |

Need a custom PTFE slide bearing solution for your application?

KINTEK specializes in the precision manufacturing of PTFE components, including seals, liners, and custom bearings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your slide bearing system is designed correctly from the start, with the right material selection and specifications to maximize performance and longevity.

We offer custom fabrication from prototypes to high-volume orders. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What should be considered when choosing a manufacturer for PTFE-lined bearings? Ensure Long-Term Reliability and Performance

- Are Teflon PTFE sheets safe for food-related uses? Ensuring Food Safety with Pure PTFE

- Why is surface treatment necessary for PTFE sheets used in tank linings? Ensuring a Secure and Reliable Bond

- What is the primary function of PTFE expansion bellows? Solve Movement and Corrosion Challenges

- What electrical properties do PTFE-coated O-rings possess? Superior Surface Insulation for Static Seals

- How did PTFE lined butterfly valves address corrosion resistance challenges? Provide a Robust Barrier Against Corrosive Media

- What applications are suitable for bronze-filled PTFE? Enhance High-Load Performance with Durable PTFE

- In what applications are PTFE balls highly functional? Ideal for Corrosive, Self-Lubricating Systems