At its core, a PTFE lined butterfly valve solves corrosion challenges by creating a complete, chemically inert barrier. This design uses a thick Polytetrafluoroethylene (PTFE) lining to completely isolate the corrosive fluid from all metal parts of the valve, combining the structural strength of metal with the superior chemical resistance of a fluoropolymer.

The fundamental advantage is not in making the valve from a better material, but in intelligently shielding a cost-effective structural material. This provides an economical and highly durable solution for controlling the flow of aggressive media that would quickly degrade traditional valves.

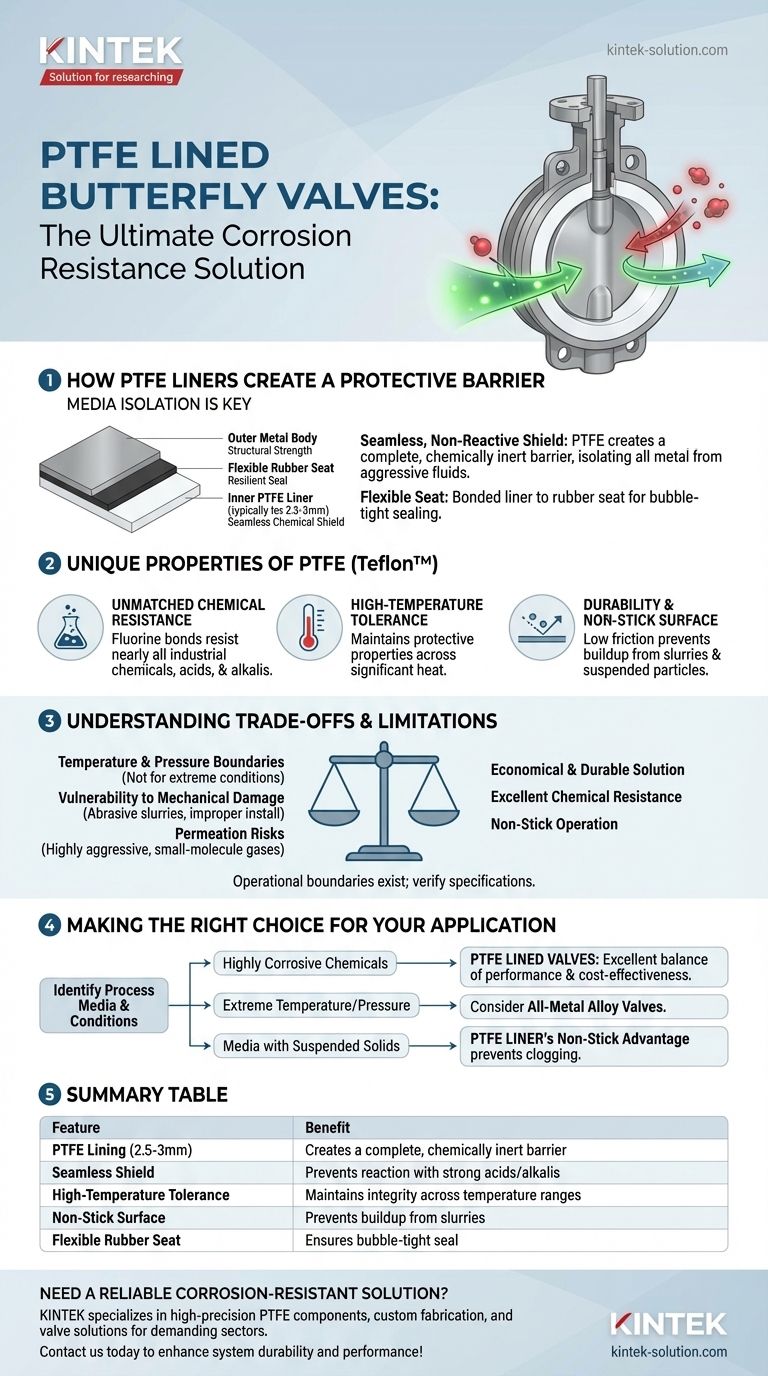

How PTFE Liners Create a Protective Barrier

The primary strategy of a PTFE lined valve is media isolation. The design ensures that the liquid or gas flowing through the pipe never makes physical contact with the valve's metal body or core components.

The Anatomy of the Liner

A thick layer of PTFE, typically 2.5-3mm, is molded to the interior of the valve body. This lining also extends to cover the face of the valve disc, which is the component that rotates to control flow.

A Seamless, Non-Reactive Shield

This seamless coating acts as a complete shield. Because PTFE is one of the most chemically inert substances known, it does not react with strong acids, alkalis, or other harsh chemicals.

The Role of the Seat

The PTFE liner is often bonded to a flexible rubber seat. This backing provides the resilience needed to create a bubble-tight seal when the valve is closed, ensuring both internal and external protection.

The Unique Properties of PTFE

PTFE, widely known by the brand name Teflon, is not just coincidentally good for this application; its molecular structure makes it uniquely suited for hostile environments.

Unmatched Chemical Resistance

The fluorine atoms in PTFE's molecular structure create an incredibly strong and stable bond. This makes the material resistant to nearly all industrial chemicals and solvents.

High-Temperature Tolerance

PTFE maintains its integrity and protective properties across a wide range of temperatures, allowing these valves to be used in processes that involve significant heat.

Durability and Non-Stick Surface

Beyond chemical resistance, PTFE is a durable material with a very low coefficient of friction. This non-stick quality is highly beneficial when the media contains suspended particles or slurries, as it prevents buildup and ensures smoother operation.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. Understanding their operational boundaries is critical for proper application.

Temperature and Pressure Boundaries

Every liner has specific temperature and pressure limits. Exceeding these can cause the liner to deform, lose its seal, or fail. While robust, they typically cannot handle the extreme temperatures and pressures that specialized all-metal alloy valves can.

Vulnerability to Mechanical Damage

The effectiveness of the valve is entirely dependent on the integrity of the liner. Abrasive slurries with sharp particles or improper installation can scratch or gouge the liner, creating a weak point for a corrosive attack on the underlying metal.

Permeation Risks

With certain highly aggressive, small-molecule gases or chemicals, permeation through the liner can occur over long periods. This is a specialized concern but important for applications involving substances like chlorine gas or hydrogen fluoride.

Making the Right Choice for Your Application

Selecting the correct valve hinges on a clear understanding of your process media and operational conditions.

- If your primary focus is handling highly corrosive chemicals: PTFE lined valves offer an excellent balance of performance and cost-effectiveness by completely isolating the media.

- If your primary focus is extreme temperature or pressure: You must verify the valve's specifications or consider an all-metal valve constructed from a suitable exotic alloy.

- If you are managing media with suspended solids: The non-stick properties of the PTFE liner provide a distinct advantage, reducing the risk of clogging and ensuring reliable operation.

Ultimately, using a PTFE liner is an elegant engineering solution that provides a robust and economical defense against corrosion for a vast range of demanding industrial processes.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Lining (2.5-3mm) | Creates a complete, chemically inert barrier isolating media from metal parts |

| Seamless Shield | Prevents reaction with strong acids, alkalis, and harsh chemicals |

| High-Temperature Tolerance | Maintains integrity across wide temperature ranges |

| Non-Stick Surface | Prevents buildup from slurries and suspended particles |

| Flexible Rubber Seat | Ensures bubble-tight seal when valve is closed |

Need a reliable corrosion-resistant valve solution for your demanding applications? KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware for semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get valves that perfectly match your chemical resistance and operational requirements. Contact us today to discuss your specific needs and discover how our PTFE expertise can enhance your system's durability and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems